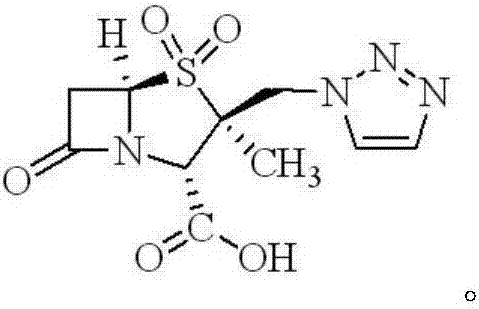

Synthetic method of tazobactam acid

A technology for the synthesis of tazobactam acid, applied in the direction of organic chemistry, etc., can solve the problems of long synthesis process steps, many by-products, complicated process, etc., and achieve the goal of improving yield and quality, improving quality, and reducing reaction temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

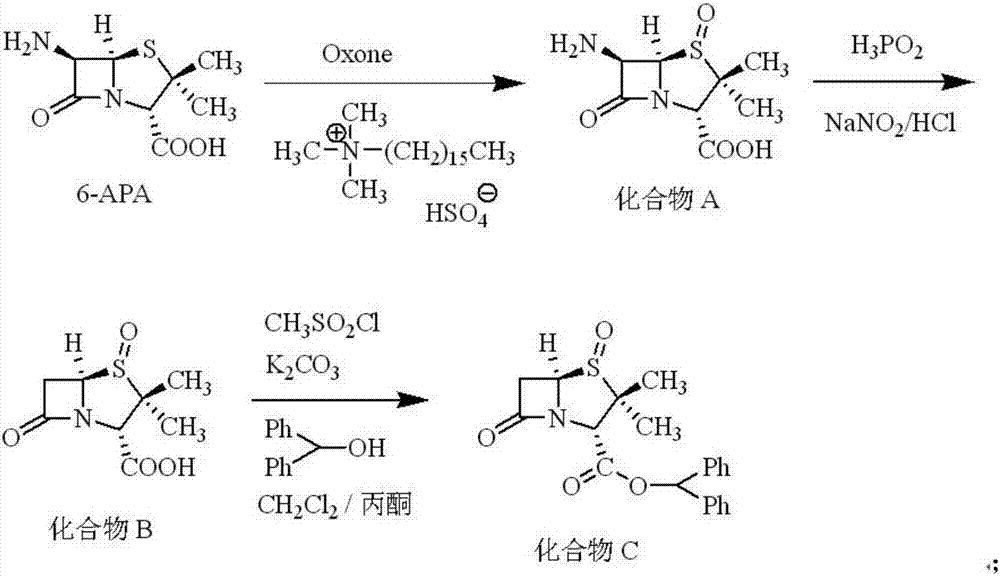

Embodiment 1

[0031] The synthesis of embodiment 1 compound C

[0032] Put 300mL of water, 100mL of acetone, 21.63g (0.10mol) of 6-APA, 3.82g (0.01mol) of hexadecyltrimethylammonium bisulfate into a 1000mL four-necked bottle, stir and cool down to 0-5°C, time-consuming Add 33.81g (0.055mol) Oxone (2KHSO 5 ·KHSO 4 ·K 2 SO 4 compound salt), reacted at 0-5° C. for 2 h, and when the residual 6-APA detected by HPLC was less than 1%, the reaction was terminated to obtain compound A.

[0033] The above reaction system was cooled to -20~-10°C, 50g of hydrochloric acid with a mass fraction of 36% was added, and 26.4g of an aqueous solution of hypophosphorous acid (0.20mol of hypophosphorous acid) with a mass fraction of 50% was added dropwise. The g mass fraction is 30% sodium nitrite aqueous solution (sodium nitrite is 0.20 mol), after dripping, keep warm for 2 hours, when the remaining compound A is less than 1% as detected by HPLC, the reaction is terminated to obtain compound B.

[0034]Hea...

Embodiment 2

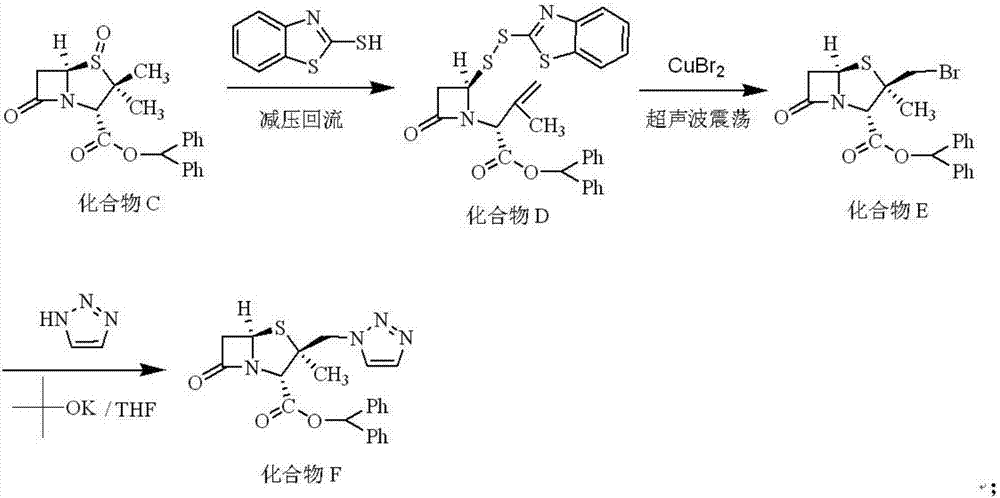

[0037] The synthesis of embodiment 2 compound F

[0038] Install a water separator on the 500mL four-necked bottle with a serpentine condenser, install a vacuum tube connected to the vacuum pump and a valve for adjusting the pumping volume on the upper part of the serpentine condenser, and put 200mL into the four-necked bottle Toluene, 38.35g (0.10mol) of compound C, 16.73g (0.10mol) of 2-mercaptobenzothiazole, by adjusting the pumping volume, the internal temperature is controlled at 70-80°C, and the pressure is refluxed for 3h, and the residue of compound C is detected by HPLC. 1%, end the reaction. Concentrate to dryness under reduced pressure, add 200mL tetrahydrofuran and stir to dissolve, filter off the insoluble matter, and concentrate the filtrate to dryness under reduced pressure to obtain compound D as a white foam.

[0039] Dissolve compound D in 200mL of dichloromethane, insert an ultrasonic vibrating rod into the reaction bottle, add 23.46g (0.105mol) copper brom...

Embodiment 3

[0050] The synthesis of embodiment 3 tazobactamic acid

[0051] 100mL methylene chloride, 50mL acetone, 43.45g (0.10mol) compound F, 16.33g mass fraction of 50% hydrogen peroxide (hydrogen peroxide is 0.24mol), 0.024g sodium polyphosphate (which is 50 % hydrogen peroxide weight of 0.15%), cooled to -5 ~ 0 ℃, dropwise added 24.50g (0.24mol) acetic anhydride, exothermic, temperature control 0 ~ 5 ℃, after dropping, keep warm for 4h, when HPLC detects that the compound F residue is less than 1%, end the reaction. Add 200 mL of 5% sodium sulfite aqueous solution to the reaction system, stir for 10 min, let stand to separate layers, extract the water layer with 100 mL of dichloromethane, combine the dichloromethane layers to about 300 mL, and obtain a dichloromethane solution of compound G.

[0052] Transfer the dichloromethane solution of compound G from the previous step into a 1000 mL four-necked flask, add 100 mL of methanol, cool down to -15 to -10 °C, add 100 mL of trifluoro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com