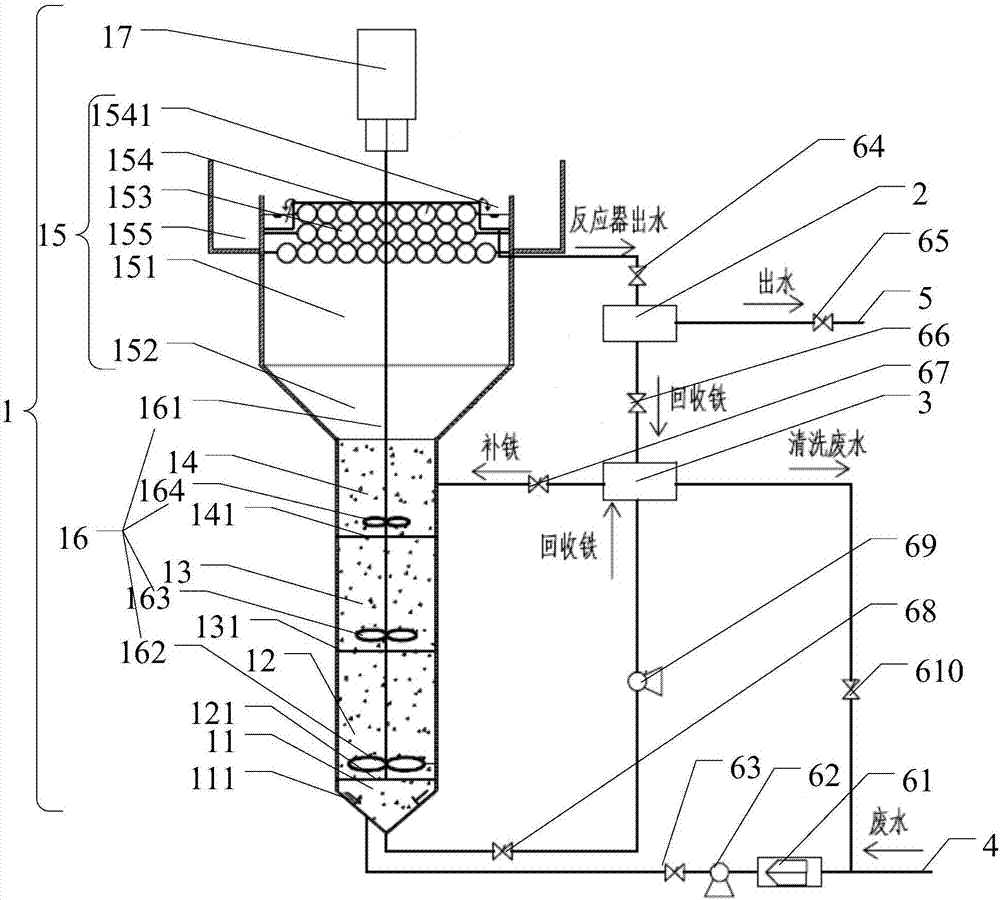

System for waste water treatment by utilizing fluidized state partition iron powder

A technology for treating wastewater and fluidized state, applied in filtration treatment, sedimentation treatment, water/sewage treatment, etc., can solve the problems of increased treatment cost, affecting service life and treatment effect, and high cost of nano-zero-valent iron

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0175] Wastewater from a pharmaceutical factory, after necessary pretreatment, the COD concentration in the wastewater is about 8000mg / L, the content of chlorinated organic matter is about 340mg / L, and the pH value is about 4.5.

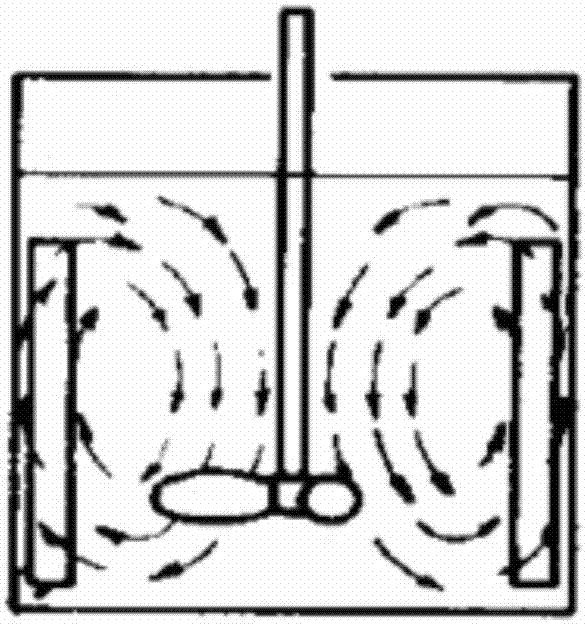

[0176]The treatment process of pharmaceutical wastewater is as follows: first, open the water inlet control valve and the water inlet lift pump, so that the waste water flows into the water inlet of the reactor's mud scraping area from the waste water inlet pipe, and adjust the water inlet flow through the water inlet lift pump during this process. And measured by the water flow meter. After the waste water flows into the mud scraping area, it flows into the primary reaction area through the first water distribution plate, flows into the primary intensified reaction area through the second water distribution plate, and flows into the secondary intensified reaction area through the third water distribution plate. During the flow process, driven by the...

Embodiment 2

[0182] Wastewater from a chemical plant, after necessary pretreatment, the COD concentration in the wastewater is about 7600mg / L, the chloroform content is 500mg / L, and the pH value is about 3.8.

[0183] The treatment process of chemical wastewater is as follows: first, open the water inlet control valve and the water inlet lift pump, so that the waste water flows into the water inlet of the reactor's mud scraping area from the waste water inlet pipe, and adjust the water inlet flow through the water inlet lift pump during this process. And measured by the water flow meter. After the waste water flows into the mud scraping area, it flows into the primary reaction area through the first water distribution plate, flows into the primary intensified reaction area through the second water distribution plate, and flows into the secondary intensified reaction area through the third water distribution plate. During the flow process, driven by the stirring motor, the axial flow propul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com