Automatic bed material adding system

A bed material and automatic technology, applied in the field of automatic bed material adding system, can solve the problems of high labor intensity and serious dust.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019]In order to make the objects, technical solutions, and advantages of the present invention, the present invention will be further described in detail below with reference to the accompanying drawings. It should be understood that these descriptions are merely exemplary and are not to limit the scope of the invention. Further, in the following description, a description of known structures and techniques is omitted to avoid unnecessary obscuring the concepts of the present invention.

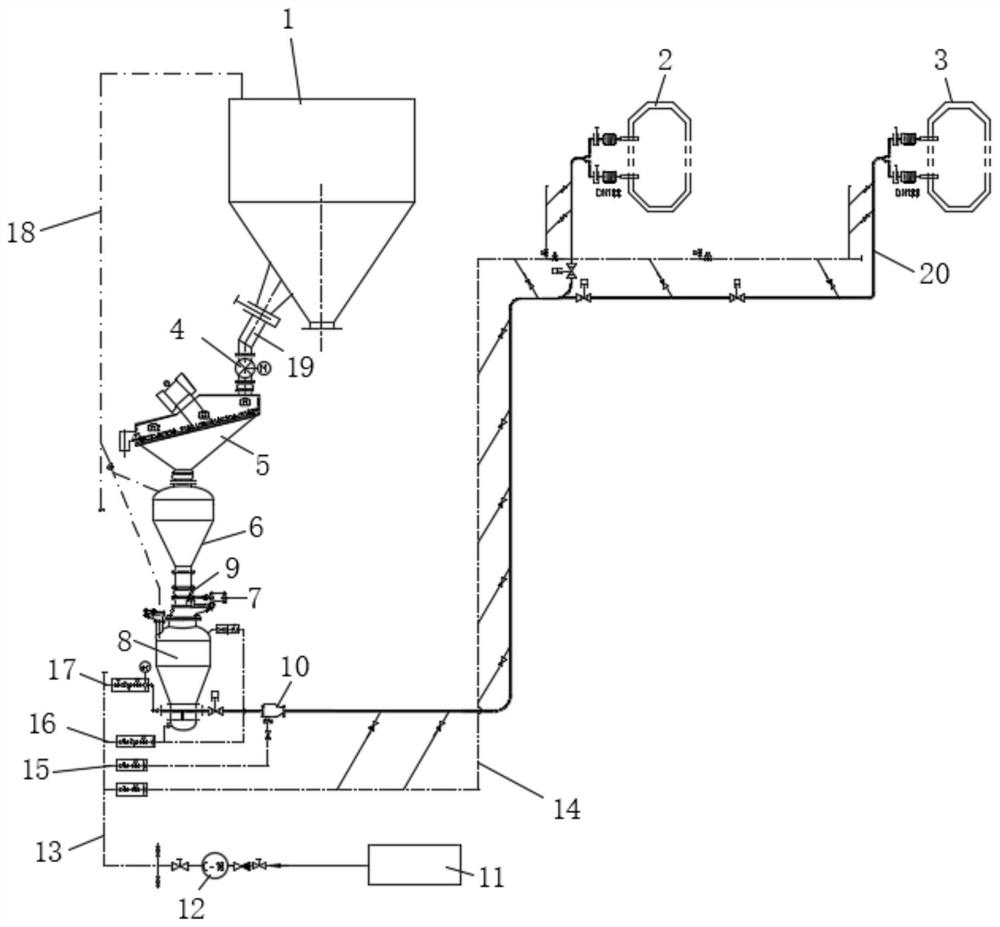

[0020]Such asfigure 1As shown, the animal bed adding system proposed by the present invention includes a slag bin 1, a first boiler 2, a second boiler 3, a variable frequency electric feeder 4, a vibrating screen 5, a buffer position 6, a transmitting device 8, and a conveying pipe 20. The bottom of the slag bun 1 is fixed to the discharge tube 19, and the bottom portion of the discharge tube 19 is mounted, and the bottom connection of the variable frequency electric feeder 4 has a vibrating screen ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com