Variable volume condenser for capillary pumped loop

A technology of condenser and capillary pump, applied in the field of variable volume condenser, can solve the problems such as the capillary pump ring cannot be started smoothly, the internal volume cannot be adjusted, the boiling point of liquid rises, etc., so as to improve the operation safety and service life, maintain the pressure Stabilizing and reducing the effect of internal pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

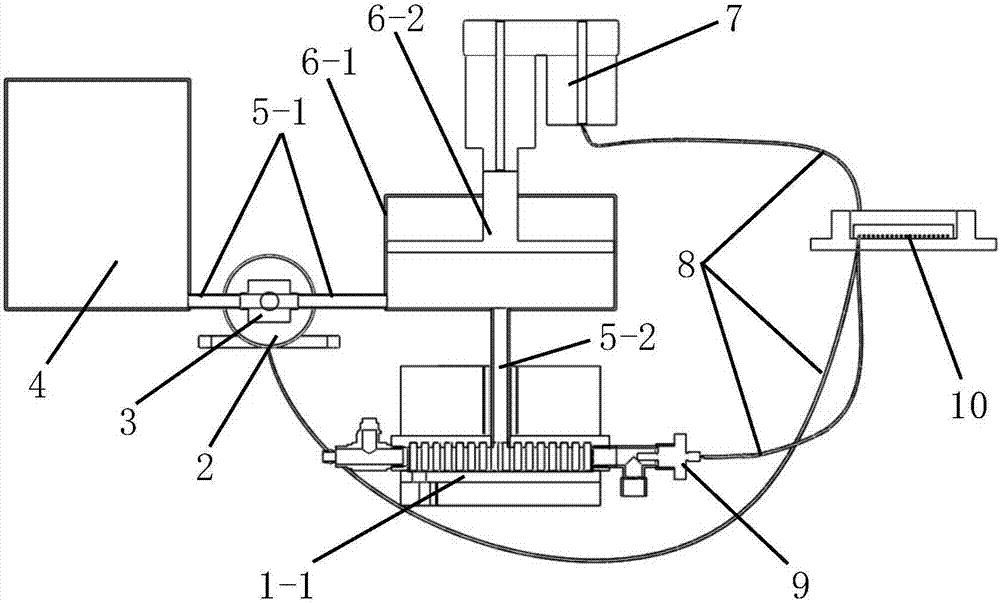

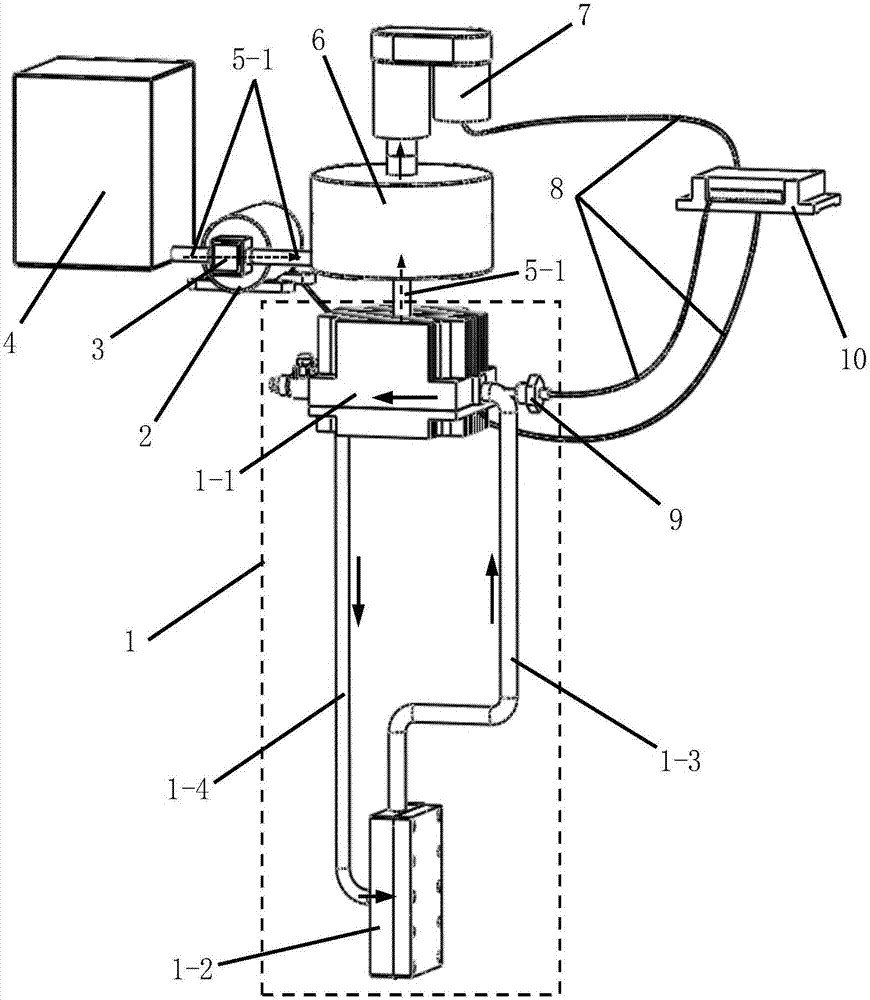

[0027] Such as Figure 1~4 A variable volume condenser applied to a capillary pump ring is shown, including a capillary pump ring system 1, a water pump 2, a solenoid valve 3, a liquid storage chamber 4, a cylinder 6, a linear motor 7, a cable 8, a pressure sensor 9, Single-chip microcomputer 10 and other components. The capillary pump ring system 1 includes a condenser 1-1, an evaporator 1-2, a steam pipe 1-3, and a liquid pipe 1-4. The cylinder 6 includes a cylinder wall 6-1 and a piston 6-2. The bottom of the cylinder 6 and the top of the condenser 1-1 each have an opening and are sealed and connected by the second copper pipe 5-2. The electromagnetic valve 3 is installed at the inlet of the water pump 2, and the water flow of the water pump 2 controls the opening and closing of the electromagnetic valve 3, so as to realize the synchronous operation of the water pump 2 and the electromagnetic valve 3, and ensure the air tightness inside the capillary pump ring system 1. ...

Embodiment 2

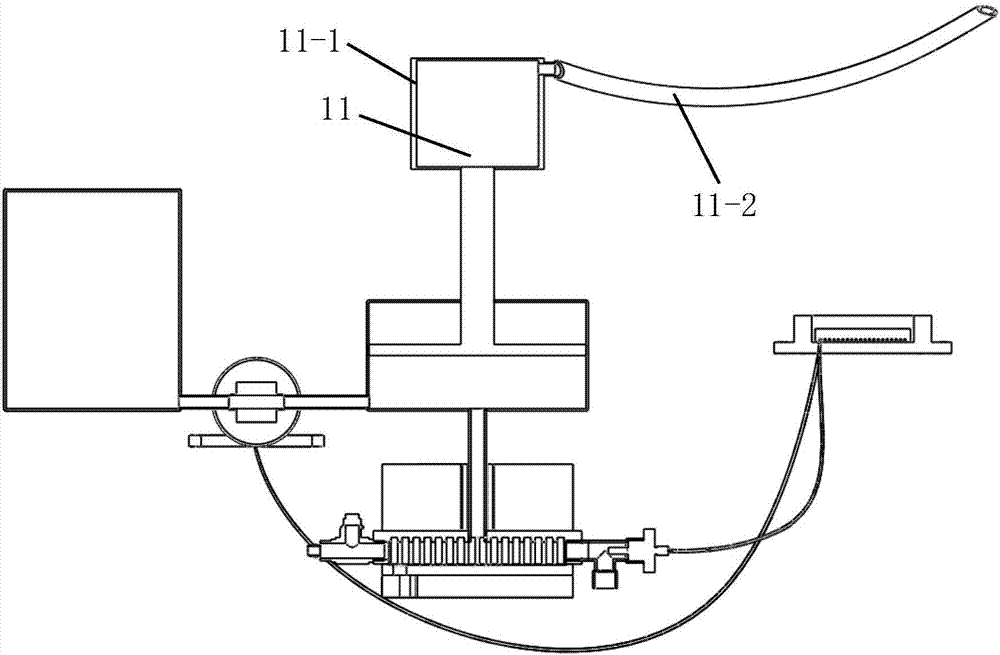

[0031] In this embodiment, a constant pressure pneumatic cylinder 11 is used instead of the linear motor 7 . The constant pressure pneumatic cylinder includes a constant pressure cylinder 11-1 and a constant pressure pipe 11-2. The constant pressure tube 11-2 is externally connected to a constant pressure source, and the constant pressure is set as P 0 . Constant pressure cylinder 11-1 is fixedly connected with piston 6-2. When the thermal load of the electronic chip rises, the internal pressure of the capillary pump ring system 1 rises, exceeding the set constant pressure P 0, 6-2 The piston pushes the constant pressure cylinder 11-1 to move upward, and the internal volume of the capillary pump ring system 1 expands; when the heat load of the electronic chip decreases, the internal pressure of the capillary pump ring system 1 drops and is lower than the set constant pressure P 0 , the constant pressure cylinder 11-1 pushes the piston 6-2 to move down, and the internal volu...

Embodiment 3

[0033] In this embodiment, the air bag 12 is used instead of the cylinder 6 . The bottom of the airbag 12 is sealed to the condenser 1-1 through the second copper tube 5-2, the left side of the airbag 12 is sealed to the water pump 2 through the first copper tube 5-1, and the top of the airbag 12 is connected to the straight line through the tappet 12-1. The motor 7 is rigidly connected. When the pressure of the capillary pump ring system 1 changes, the single-chip microcomputer 10 issues instructions to control the linear motor 7 to drive the tappet 12-1 to move up and down to realize the compression or expansion of the air bag, thereby changing the internal volume of the capillary pump ring system 1 . Other actions are the same as in Embodiment 1.

[0034] The invention can adjust the internal volume of the capillary pump ring to adapt to different heat load working conditions, ensure that the internal pressure and liquid filling rate remain unchanged, improve the heat tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com