Grain boundary engineering

A grain, average grain size technology, applied in metal processing equipment, magnetic objects, magnets, etc., can solve problems such as limited resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

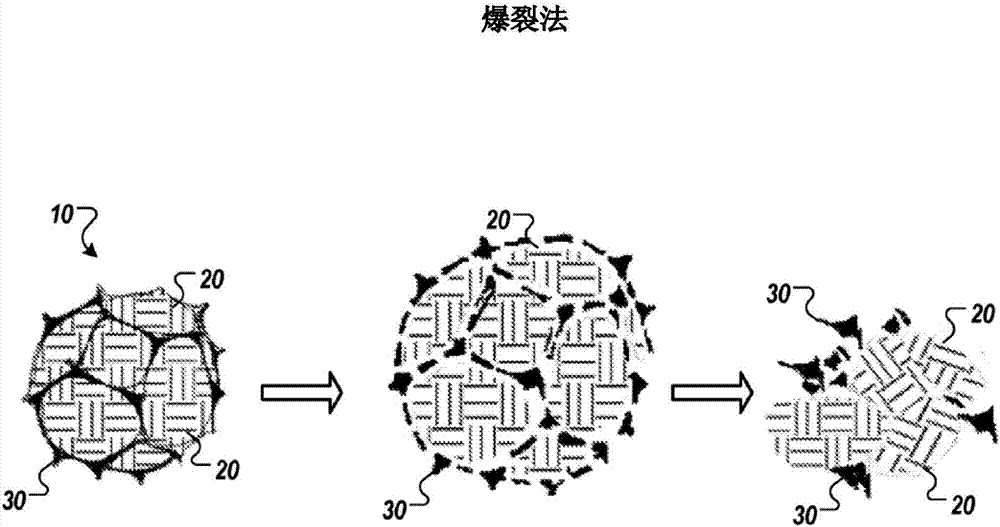

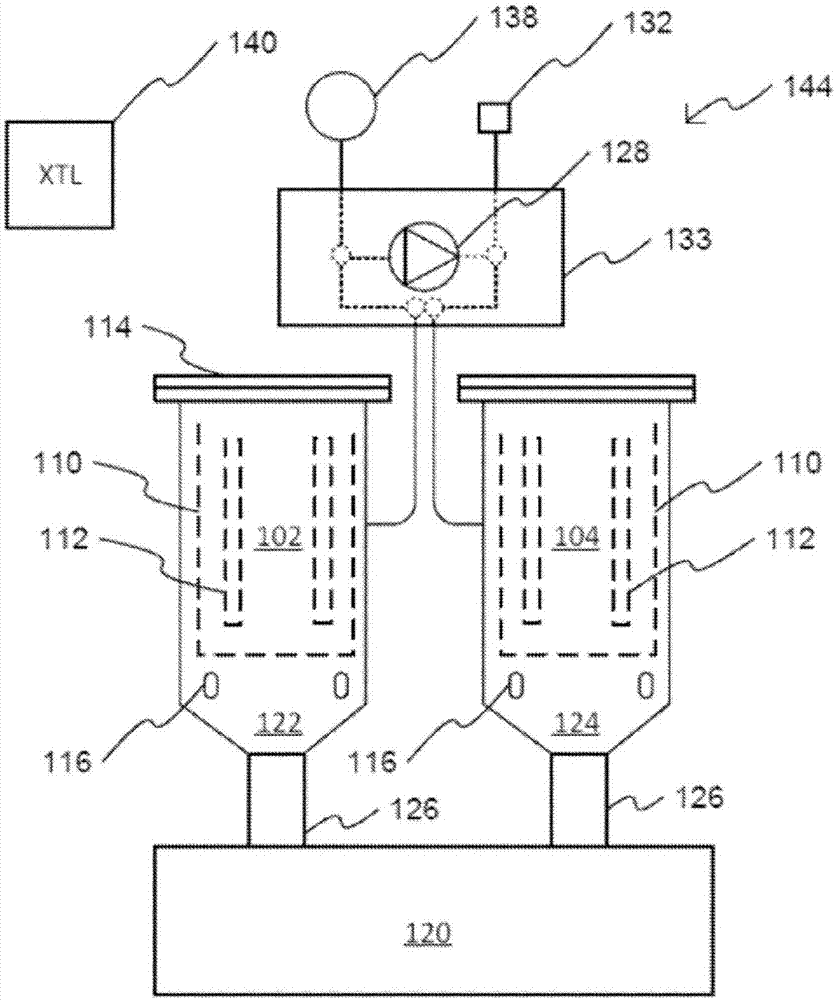

Method used

Image

Examples

Embodiment 1

[0115] These examples show that the GBE method can be used to improve the overall magnetic properties of permanent magnets with minimal dopants. For example, GBE method can lead to 27% increase in coercivity and 0% decrease in remanence (such as Image 6 As shown in), or 83% increase in coercivity and 6% decrease in remanence (as Figure 7 As shown in), or 60% increase in coercivity and 3% decrease in remanence (as Figure 8 Shown in). E.g, Image 6 An example of a variant of a high-energy Nd-Fe-B type sintered magnet with an additive of 0.5 atomic% (for example, Nd or Dy) is shown. The final magnet with 0.5 atomic% additives has a remanence (Br) of 1.423T, a coercivity (iHc) of 1042kA / m and 391kJ / m 3 The energy product (BHmax). Figure 7 An example of a variant of an Nd-Fe-B type sintered magnet with a 3 atomic% additive (for example Dy) that produces a high coercivity suitable for high temperature applications is shown. The final magnet with 0.3 atomic% additives has a remane...

Embodiment 2

[0175] Magnets produced using GBE technology have improved temperature performance. For example, magnets produced using GBE technology have improved thermal stability and improved magnetic properties. Recycled magnets (such as, for example, Nd-Fe-B recycled bodies from end-of-life products) can have improved thermal stability compared to input materials (e.g., pure materials) processed to produce recycled Nd-Fe-B magnets . Magnets made of imported nascent or mostly nascent Nd-Fe-B magnetic materials and processed by GBE technology can have improved thermal stability compared to magnets made by other methods.

[0176] Table 5 shows the ICP composition of two starting magnets (starting magnet 1 and starting magnet 2) and two final magnets (final magnet 1 and final magnet 3) made from the starting magnet. The final magnet 1 contains 0.5 atomic% of additive material added using GBE technology, and the final magnets 2 and 3 respectively contain 2 atomic% and 3 atomic% of additive ma...

Embodiment 3

[0192] In some instances, GBE technology can be used to dispose of waste magnets. For example, the GBE system can generate magnets (eg, using steps 902 to 908), which includes generating discarded magnets. In some instances, another method can be used to generate scrap magnets or the scrap magnets can be received from another system through the GBE system.

[0193] The GBE system uses the above steps 910 to 918 to process scrap magnets. In some embodiments, discarded magnets and recycled magnets can have similar properties to those described in Table 8 below. As described above, for each different discarded magnet, the amount and type of elements contained in the additive material can be adjusted to obtain a final magnet with the same properties. In some examples, 1 atomic% of Nd / Pr is added to the particles formed from each waste magnet.

[0194]

[0195] The remanence (Br) of the final magnet can be 1.25T. The coercivity (iHc) of the final magnet can be 1710 kA / m. The energy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com