Hyperbranched polyamide modified polypropylene composite material and preparation method thereof

A technology of hyperbranched polyamide and composite materials, which is applied in the field of hyperbranched polyamide modified polypropylene composite materials and its preparation, can solve problems such as the application and reports of hyperbranched polymers that have not been seen, and achieve easy control of glass fiber content, The effect of good impact toughness and low raw material cost advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

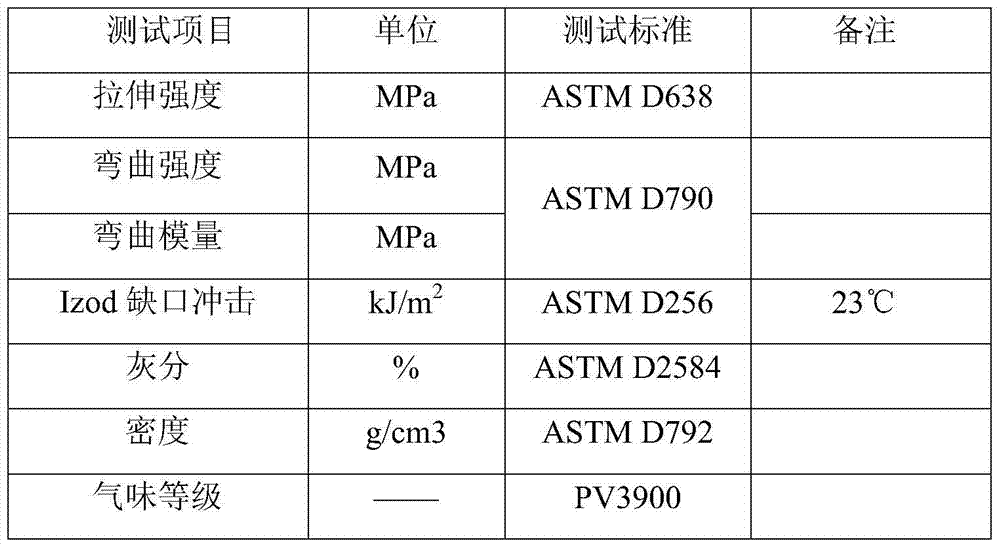

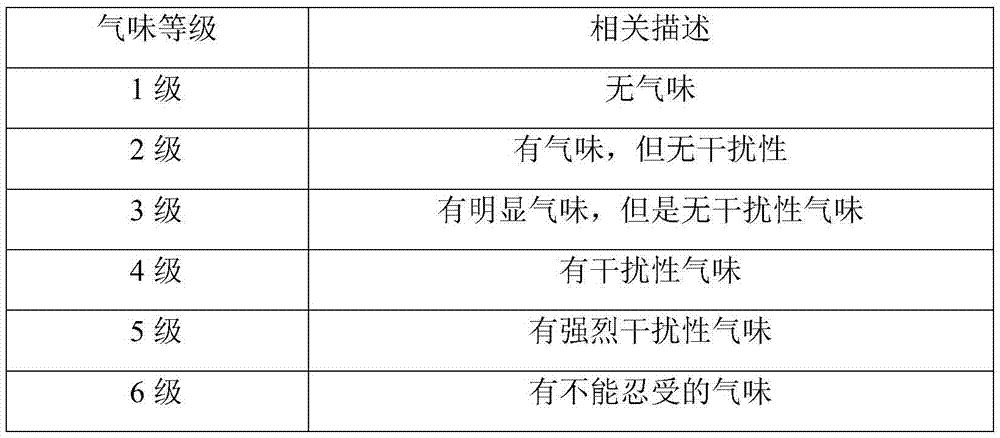

Method used

Image

Examples

Embodiment 1

[0038]65 parts of homopolypropylene (melt index 12g / 10min, test condition 230°C / 2.16Kg), 0.6 parts of alkyl-terminated hyperbranched polyamide, 0.5 parts of silane coupling agent KH550 (γ-aminopropyltriethoxy Silane), 0.02 part of antioxidant 1010, 0.04 part of antioxidant 168, 0.5 part of ethylene bisstearamide, 0.5 part of maleic anhydride grafted polypropylene, are added to the high mixer successively, and the mixing temperature is controlled at 40 ℃, mix the mixture for 3 minutes and set aside.

[0039] Preparation of polypropylene composite material: using continuous fiber-reinforced thermoplastic material impregnation equipment, adopting melt impregnation pultrusion process, adding the above mixture into the hopper of a twin-screw extruder for heating and melting, wherein the screw diameter of the twin-screw extruder is 20mm, The length-to-diameter ratio of the screw is 40:1, and the mixing and melting temperature is set as: the first section 170°C, the second section 18...

Embodiment 2

[0041] 60 parts of copolymerized polypropylene (melt index 15g / 10min, test condition 230°C / 2.16Kg), 0.5 parts of terminal alkyl hyperbranched polyamide, 1.5 parts of silane coupling agent KH550 (γ-aminopropyltriethoxysilane ), 0.01 part of antioxidant 1076, 0.01 part of antioxidant 1098, 0.03 part of antioxidant 168, 0.02 part of antioxidant 618, 0.3 part of calcium stearate, 0.3 part of polyethylene wax, 1.5 part of maleic anhydride graft Polypropylene is sequentially added into the high mixer, the mixing temperature is controlled at 40°C, and the mixture is set aside after 3 minutes.

[0042] Preparation of polypropylene composite material: using continuous fiber-reinforced thermoplastic material impregnation equipment, adopting melt impregnation pultrusion process, adding the above mixture into the hopper of a twin-screw extruder for heating and melting, wherein the screw diameter of the twin-screw extruder is 35mm, The length-to-diameter ratio of the screw is 40:1, and the...

Embodiment 3

[0044] 25 parts of homopolypropylene (melt index 5g / 10min, test condition 230°C / 2.16Kg), 30 parts of copolymerized polypropylene (melt index 8g / 10min, test condition 230°C / 2.16Kg), 0.4 part of terminal alkyl overbranch Polyamide, 2.5 parts of γ-2,3 glycidoxy-propyltrimethoxysilane, 0.01 part of antioxidant 1010, 0.01 part of antioxidant 1098, 0.01 part of antioxidant 1076, 0.03 part of antioxidant 168 , 0.03 part of antioxidant 618, 0.3 part of ethylene bisstearamide, 0.2 part of calcium stearate, 0.2 part of pentaerythritol stearate, and 2.5 parts of maleic anhydride grafted polypropylene are added to the high mixer in sequence, The temperature of the mixture is controlled at 60° C., and it is set aside after 4 minutes of mixing.

[0045] Preparation of polypropylene composite material: using continuous fiber-reinforced thermoplastic material impregnation equipment, adopting melt impregnation pultrusion process, adding the above mixture into the hopper of a twin-screw extrude...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com