Polyester composition and its preparation method

A composition and polyester technology, applied in the field of materials, can solve problems such as unsatisfactory crystallization performance, influence on tensile strength, rigid thermal deformation temperature, impact resistance, creep resistance, crystallization rate, etc., and achieve short molding time , increase the crystallization rate, and have excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

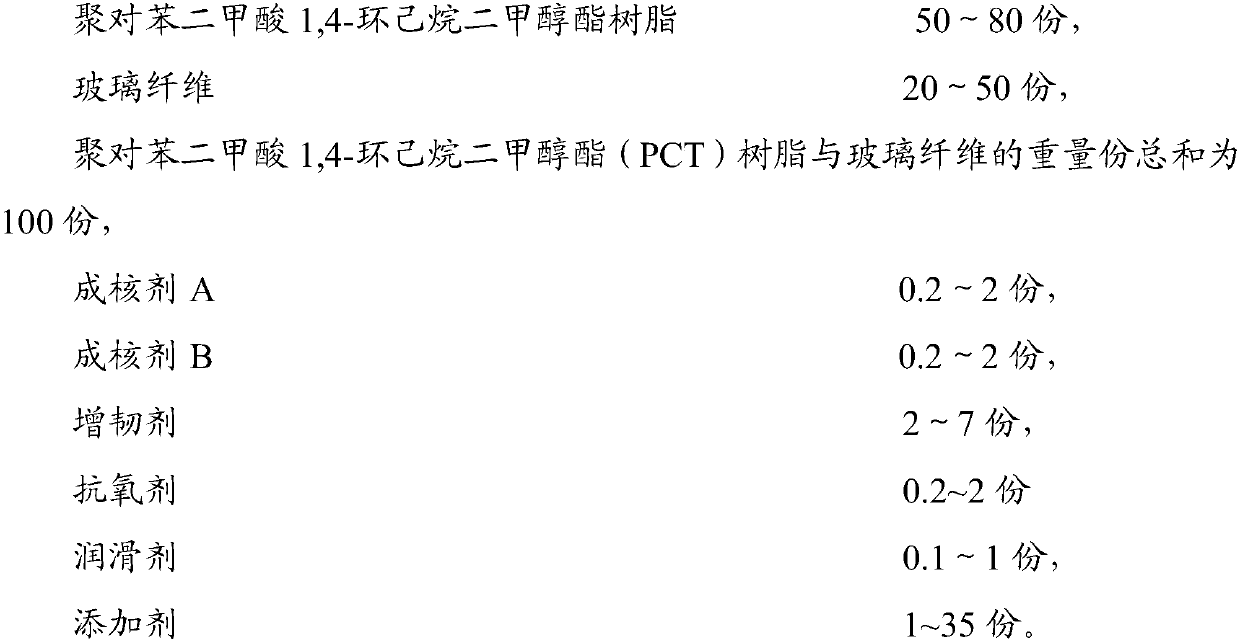

[0053] A polyester composition of the present embodiment is prepared from the following raw materials:

[0054]

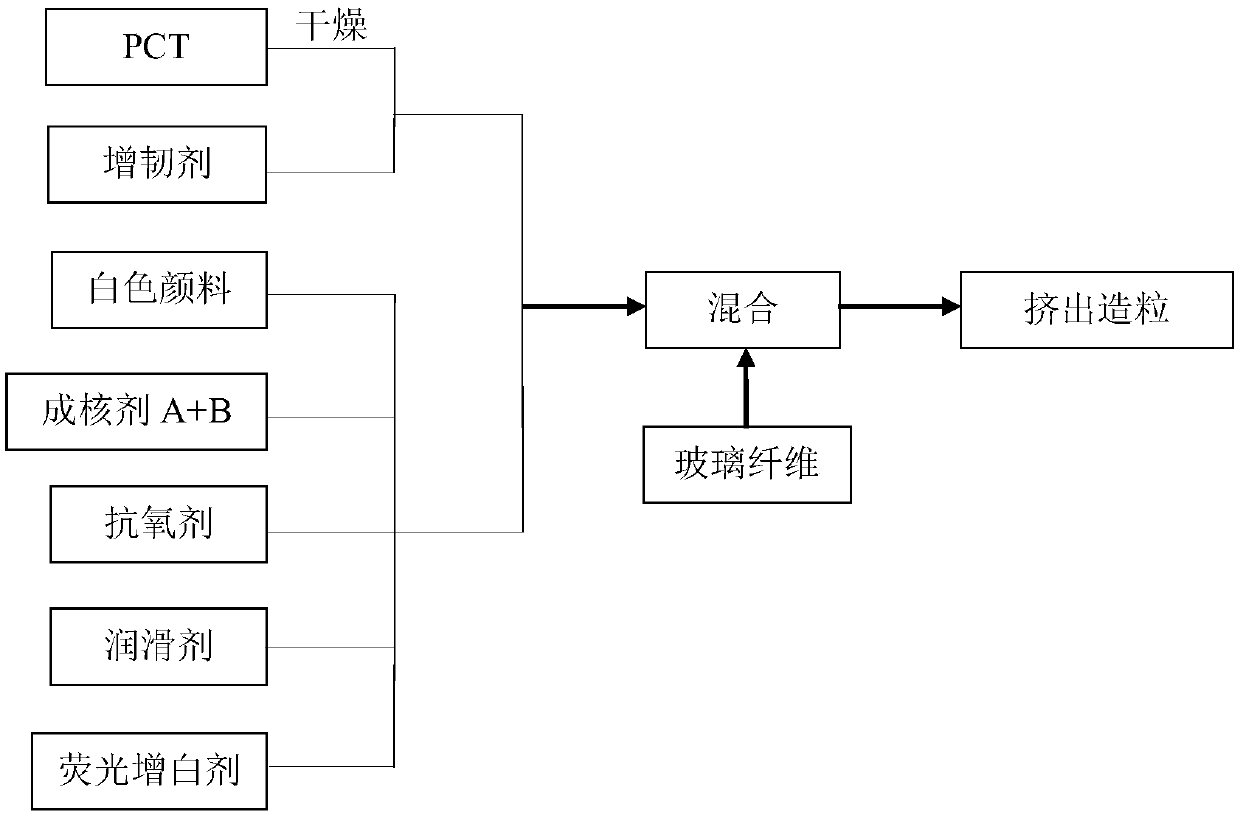

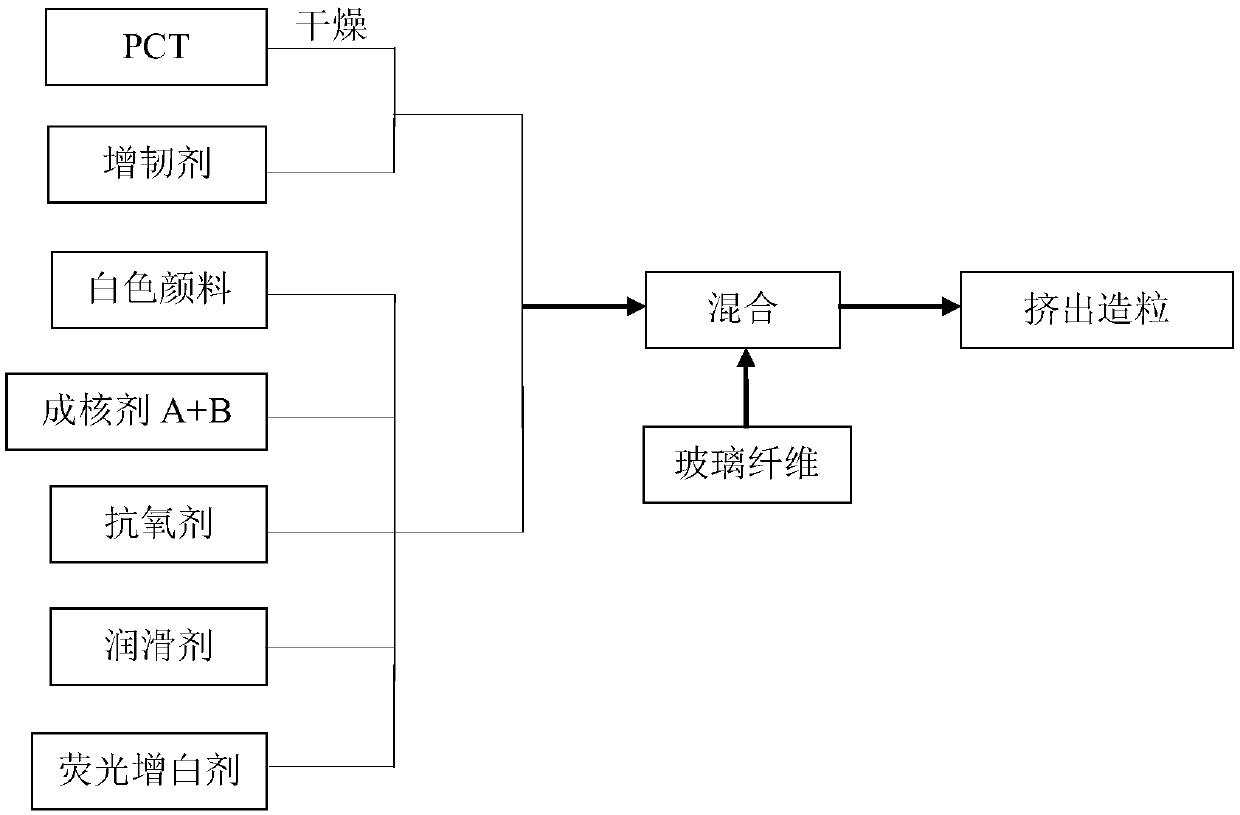

[0055] The preparation method of above-mentioned polycarbonate composition, comprises the following steps:

[0056] (1) Place the PCT resin at 110° C., dry it for 6 hours, and cool it. Add the cooled PCT resin and the toughening agent into a high-speed mixer for pre-mixing;

[0057] (2) Add the white pigment, nucleating agent A, nucleating agent B, hindered phenolic antioxidant, phosphite antioxidant, lubricant and optical brightener to another high-speed mixer Mix, then join the obtained mixture in the high-speed mixer described in step (1) and mix;

[0058] (3) The mixture mixed in step (2) is placed in a parallel twin-screw extruder, and the glass fiber is added from the side feed of the parallel twin-screw extruder to melt and extrude, and granulate , the process parameters are as follows: the temperature of the first zone is 300°C, the temperature of the ...

Embodiment 2

[0061] A polyester composition of the present embodiment is prepared from the following raw materials:

[0062]

[0063] The preparation method of above-mentioned polycarbonate composition, comprises the following steps:

[0064] (1) Place the PCT resin at 110° C., dry it for 6 hours, and cool it. Add the cooled PCT resin and the toughening agent into a high-speed mixer for pre-mixing;

[0065] (2) Add white pigment, nucleating agent A, nucleating agent B, hindered phenolic antioxidant, phosphite antioxidant, lubricant and optical brightener to another high-speed mixer and mix, Then the mixture obtained is added to the high-speed mixer described in step (1) and mixed;

[0066] (3) The mixture mixed in step (2) is placed in a parallel twin-screw extruder, and the glass fiber is added from the side feed of the parallel twin-screw extruder to melt and extrude, and granulate , the process parameters are as follows: the temperature of the first zone is 295°C, the temperature o...

Embodiment 3

[0069] A polyester composition of the present embodiment is prepared from the following raw materials:

[0070]

[0071] The preparation method of above-mentioned polycarbonate composition, comprises the following steps:

[0072] (1) Place the PCT resin at 110°C, dry it for 6 hours, cool it, and add the cooled PCT resin and toughening agent into a high-speed mixer for pre-mixing;

[0073] (2) Add the white pigment, nucleating agent A, nucleating agent B, hindered phenolic antioxidant, phosphite antioxidant, lubricant and optical brightener to another high-speed mixer Mix, then join the obtained mixture in the high-speed mixer described in step (1) and mix;

[0074] (3) The mixture mixed in step (2) is placed in a parallel twin-screw extruder, and the glass fiber is added from the side feed of the parallel twin-screw extruder to melt and extrude, and granulate , the process parameters are as follows: the temperature of the first zone is 300°C, the temperature of the second...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com