A through-type cooling channel ultra-high molecular weight polyethylene sheet forming mold

An ultra-high molecular weight, cooling water channel technology, applied in the field of ultra-high molecular weight polyethylene sheet production equipment, can solve the problems affecting processing accuracy and product quality, uneven shrinkage of sheet edges, uneven cooling of molds, etc., to achieve uniform cooling And fast, eliminate warpage, eliminate the effect of adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following will further analyze the through-type cooling water channel ultra-high molecular weight polyethylene sheet forming mold according to the present invention according to the specific embodiments and the accompanying drawings.

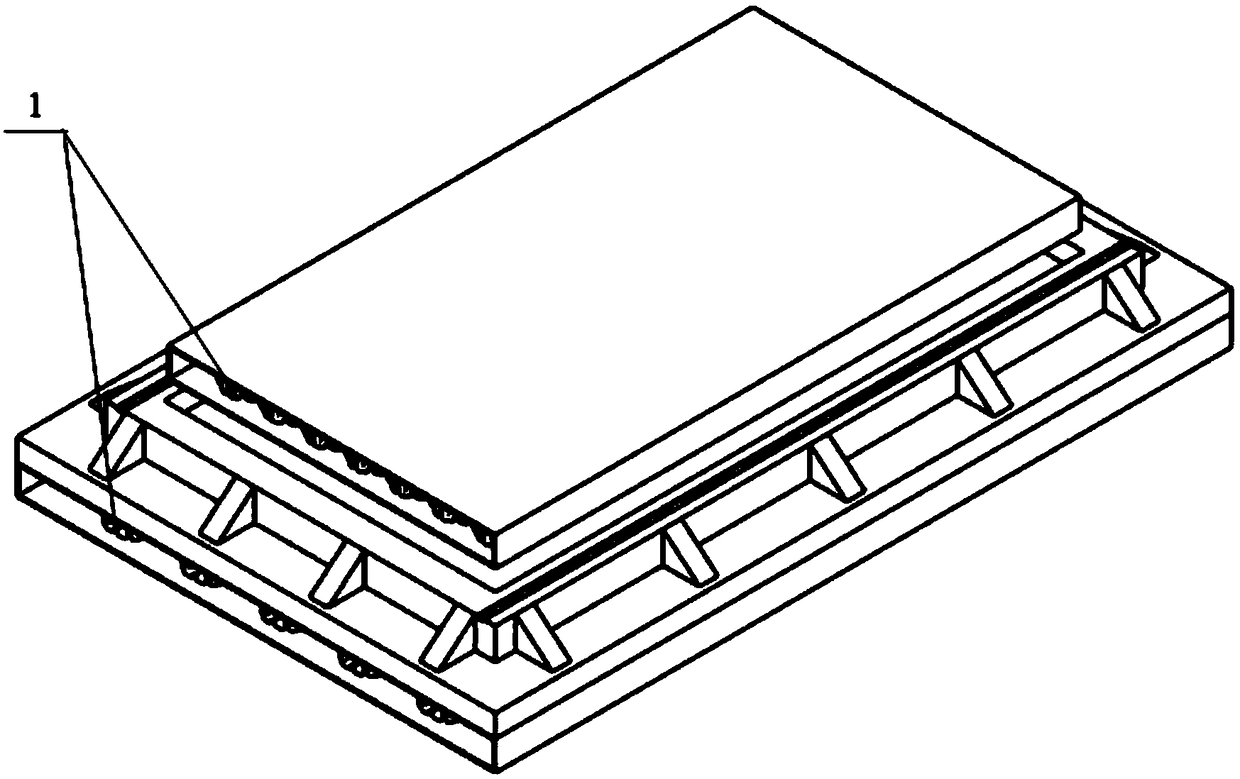

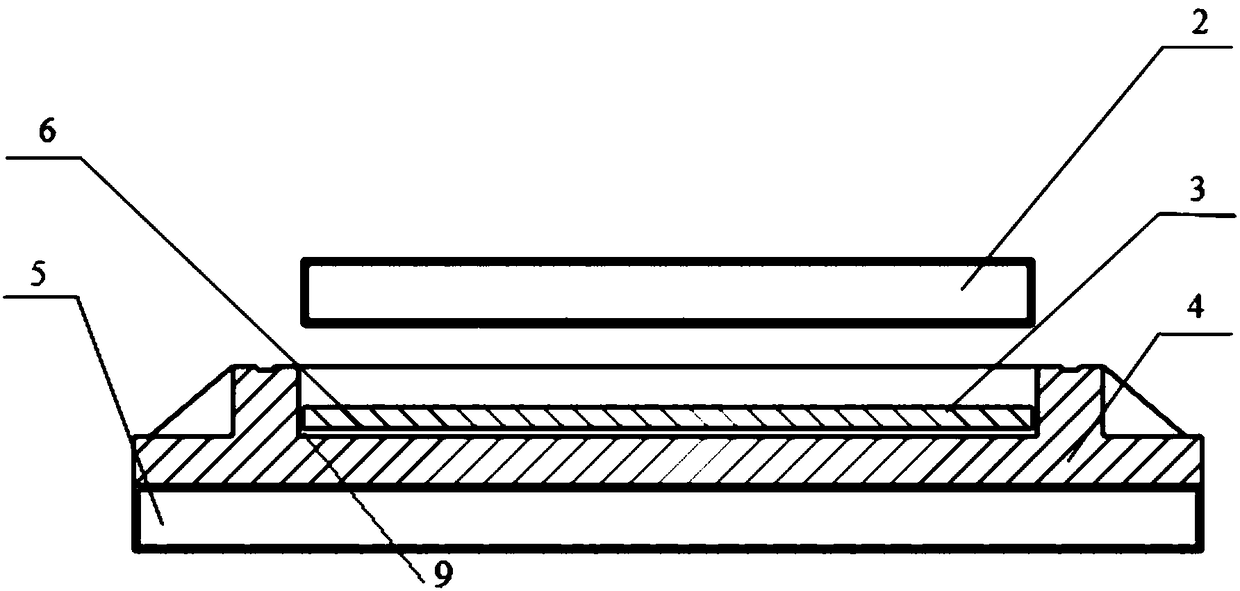

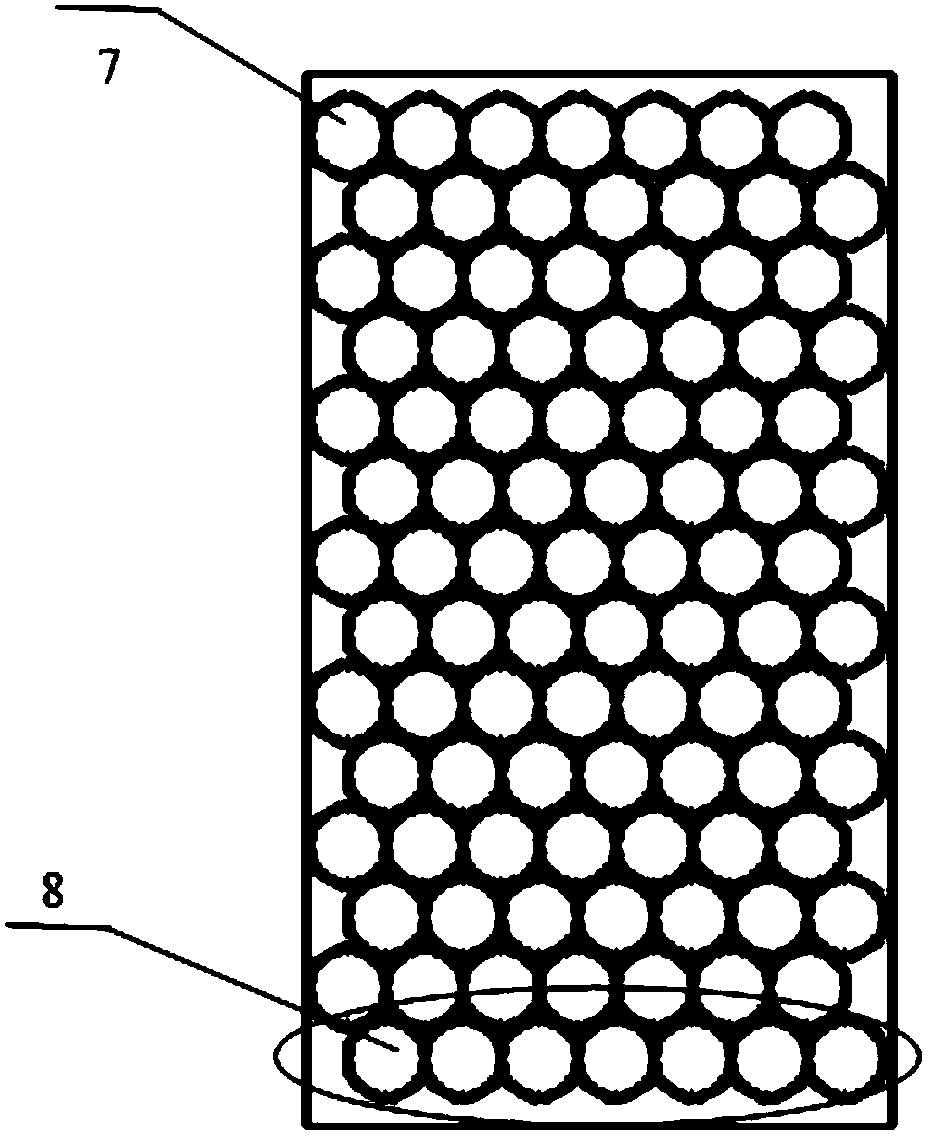

[0030] combined with figure 1 , figure 2 As shown, the through-type cooling channel ultra-high molecular weight polyethylene sheet molding mold in this example includes a honeycomb structure support device 1 , an upper cooling device 2 , an upper mold 3 , a lower mold 4 , and a lower cooling device 5 . The upper surface of the lower mold 4 is provided with a chute 9, and the feeding device slides in the chute 9 to ensure that the high molecular weight polyethylene powder 6 is evenly laid on the bottom of the cavity of the lower mold 4 . The lower mold 4 is installed on the lower cooling device 5, the length and width of the lower cooling device 5 are the same as the bottom of the lower mold 4, and the wall thickness of the lower coo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com