Super-hydrophobic material and preparation method thereof

A super-hydrophobic and super-hydrophobic technology, which is applied in the direction of pretreatment surface, special surface, and device for coating liquid on the surface, etc., can solve the problems of limitation, poor strength and durability of super-hydrophobic materials, and damage to micro-nano structures, etc., to achieve good The effect of self-cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1 (1) AZ31 magnesium alloy pretreatment: select the magnesium alloy of 3cm * 3cm * 2cm to be substrate, after polishing with sandpaper, in acetone, dehydrated alcohol, ultrasonic cleaning removes the oxide film and greasy dirt on magnesium alloy surface, finally uses Rinse with ionized water and dry with a hair dryer for later use.

[0029] (2) Prepare ZIF-8 powder, configure 0.04mol / L zinc nitrate methanol solution, 0.08mol / L 2-methylimidazole methanol solution, mix and stir them in equal volume for 5min, stir for 2h, centrifuge three times with methanol, 60 ℃ dried overnight to obtain ZIF-8 powder.

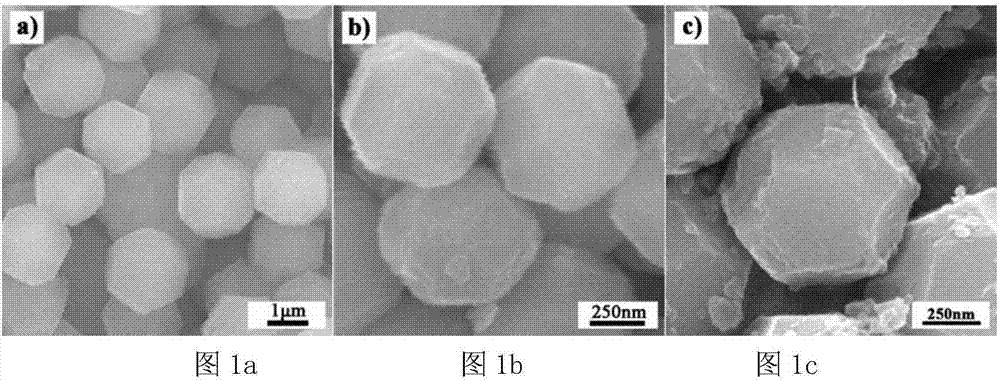

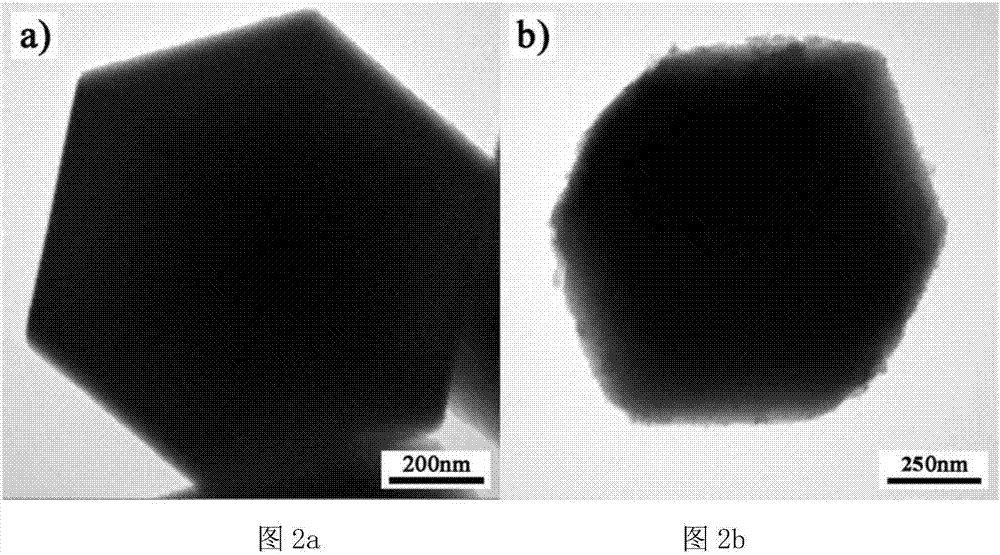

[0030] (3) To prepare ZIF-8@SiO2 powder, dissolve 80mg of ZIF-8 powder and 10mg of cetyltrimethylammonium bromide (CTAB) in 80ml of absolute ethanol, and stir for 5min. Take another small beaker, add 0.5ml of tetraethyl orthosilicate (TEOS) and 1ml of absolute ethanol for 10 minutes of ultrasonication, add 0.4ml of ammonia water to the above solution under sti...

Embodiment 2

[0035] The method for material preparation of this embodiment example is basically the same as embodiment 1, and the difference is that the stirring time for preparing ZIF-8 is 4h.

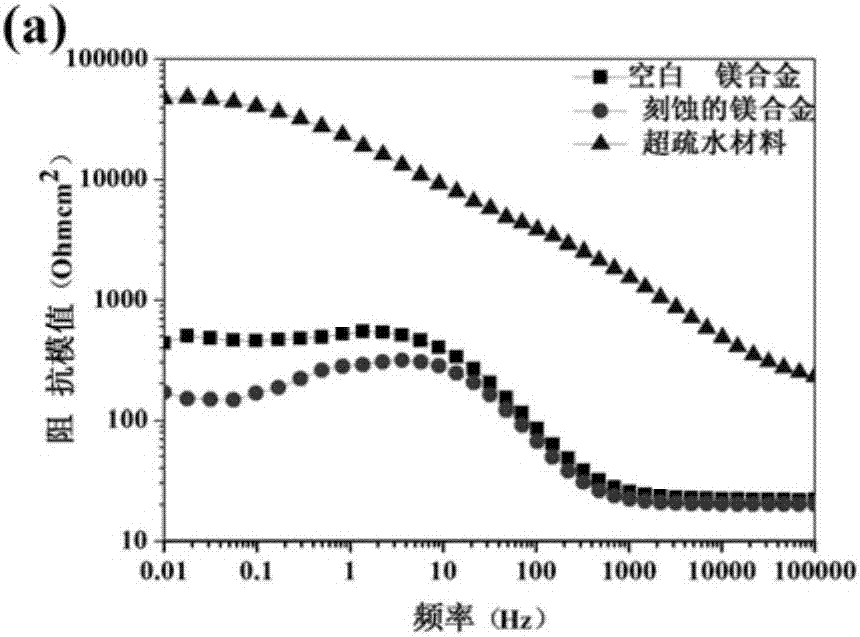

[0036] A superhydrophobic surface with a special micro-nano structure is obtained by combining the micron structure constructed by chemical etching and dip coating method. The obtained nano ZIF-8 particles are regular, with a size of about 250nm, and the final surface contact angle reaches 151°, which has good self-cleaning properties. properties and good corrosion resistance, after soaking in 3.5wt.% NaCl solution for 3 hours, the impedance modulus can still reach 7500Ωcm 2 , At the same time, the material has good wear resistance, and the friction coefficient is still 0.388 after grinding for 20 minutes.

Embodiment 3

[0038] The method for preparing the material of this embodiment is basically the same as that of Embodiment 1, except that the preparation of ZIF-8 was left standing for 24 hours.

[0039]The finally obtained ZIF-8 particles are uniformly dispersed, and the size is about 500nm, and the test contact angle reaches 150°C. The hydrophobic material still has good self-cleaning property and good corrosion resistance. After 3h, the impedance modulus can reach 8000Ωcm 2 , significantly better than the impedance modulus of the blank magnesium alloy. At the same time, the material has good wear resistance. After grinding the steel material for 20 minutes, the friction coefficient is 0.388, which is lower than that of the blank magnesium alloy.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface contact angle | aaaaa | aaaaa |

| Surface contact angle | aaaaa | aaaaa |

| Coefficient of friction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com