Super-hydrophobic epoxy solid buoyancy material, and preparation method thereof

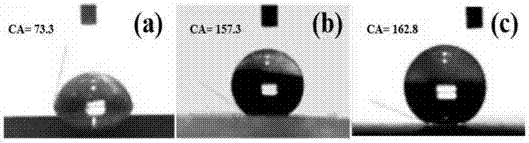

A solid buoyancy, epoxy-based technology, applied in the field of super-hydrophobic epoxy-based solid buoyancy materials and their preparation, can solve the problems of rare solid buoyancy materials, and achieve the effects of good self-cleaning, good reproducibility and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A superhydrophobic epoxy-based solid buoyancy material, calculated in parts by mass, the material comprises the following components: 100 parts of epoxy resin, 15 parts of diluent, 10 parts of toughening agent, 60 parts of curing agent, 1 part of catalyst, 40 parts of hollow microspheres, 15 parts of fluorinated acrylic prepolymer.

[0025] Described epoxy resin is epoxy resin E51.

[0026] Described diluent is ethylene glycol diglycidyl ether type epoxy diluent.

[0027] The toughening agent is an acrylonitrile-butadiene-styrene copolymer (ABS) toughening agent.

[0028] The curing agent is maleic anhydride.

[0029] The catalyst is diethylenetriamine.

[0030] The hollow microspheres are hollow glass microspheres K37 treated with KH560 surface.

[0031] The fluorinated acrylic prepolymer is fluorinated acrylic prepolymer A.

[0032] Prepare materials according to the above formula, and then use the following process to prepare:

[0033] (1) Surface treatment of ...

Embodiment 2

[0040] A superhydrophobic epoxy-based solid buoyancy material, calculated in parts by mass, the material comprises the following components: 100 parts of epoxy resin, 15 parts of diluent, 10 parts of toughening agent, 60 parts of curing agent, 1 part of catalyst, 40 parts of hollow microspheres, 15 parts of fluorinated acrylic prepolymer.

[0041] Described epoxy resin is epoxy resin E51.

[0042] Described diluent is ethylene glycol diglycidyl ether type epoxy diluent.

[0043] The toughening agent is an acrylonitrile-butadiene-styrene copolymer (ABS) toughening agent.

[0044] The curing agent is maleic anhydride.

[0045] The catalyst is diethylenetriamine.

[0046] The hollow microspheres are hollow glass microspheres K37 treated with KH560 surface.

[0047] The fluorinated acrylic prepolymer is fluorinated acrylic prepolymer C.

[0048] Prepare materials according to the above formula, and then use the following process to prepare:

[0049] (1) Surface treatment of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com