Normal temperature solidified titania sol

A titanium dioxide, room temperature curing technology, applied in the direction of titanium dioxide, chemical instruments and methods, titanium oxide/hydroxide, etc., can solve the problems of high price of organic titanium raw materials, agglomeration of nanoparticles, etc., to achieve low raw material cost, low operating temperature, Stable and transparent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Add 5ml of metatitanic acid solution with a concentration (based on titanium dioxide content) of 80g / l into the container, heat it to 55°C, adjust the pH value to 3.0 with a NaOH solution with a concentration of 90g / l, and then keep it warm for 0.5 Hours, the seed crystal transparent sol was obtained; after the obtained seed crystal transparent sol was continued to be heated to 80° C., 20 ml of 80 g / l metatitanic acid solution was added to the seed crystal transparent sol, and the reaction system was continued to be heated to 140 Boiling at ℃ for 1 hour, a white precipitate was obtained, which was filtered and washed to obtain a white filter cake; the obtained white filter cake was completely dispersed in 20ml of 3M HCl solution, and degummed at 25℃ for 8 hours to obtain a light blue transparent normal temperature Cured titanium dioxide sol.

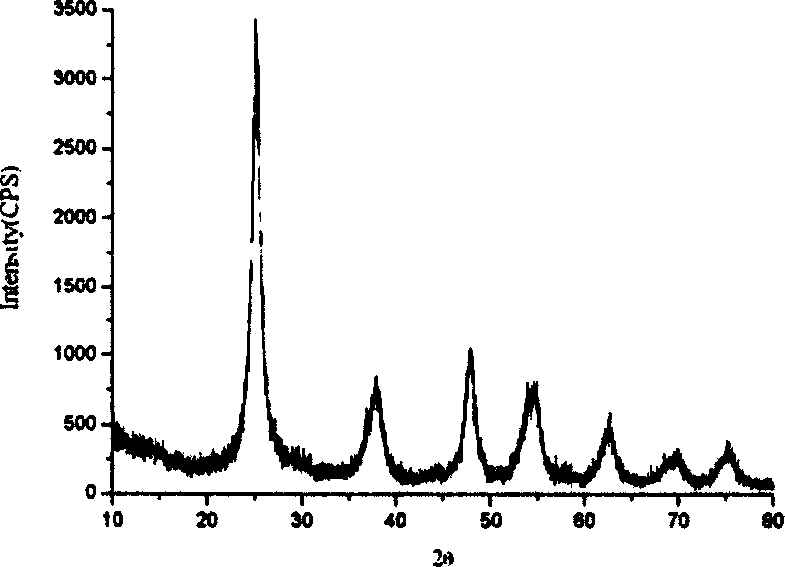

[0034] Get a small amount of the above-mentioned white filter cake, after drying at normal temperature, the XRD test shows that ...

Embodiment 2

[0037]Add 3ml of titanyl sulfate solution with a concentration (based on titanium dioxide content) of 200g / l into the container, heat it to 28°C, adjust the pH value to 2.5 with a KOH solution with a concentration of 98g / l, and stir the above mixed solution for 30 Minutes later, the reaction system was heated to 35° C., and kept under stirring for 180 minutes to obtain a seed crystal transparent sol; then 30 ml of a 200 g / l titanyl sulfate solution was added to the prepared seed crystal transparent sol, and The reaction system was continued to be heated to 100°C and reacted for 5 hours. The resulting white precipitate was filtered and washed with 3% ammonia and water to obtain a white filter cake; the resulting filter cake was divided into two and dispersed in 10 and 20ml of 1.5 M HNO 3 In the solution, degumming at a temperature of 60° C. for 4 hours can obtain light blue transparent titanium dioxide sols with concentrations of 200 g / l and 100 g / l respectively.

[0038] Acco...

Embodiment 3

[0040] Add 10ml of titanium tetrachloride solution with a concentration (in terms of titanium dioxide content) of 200g / l into the container, heat it to 50°C, and adjust the pH value to 3.0 with a NaOH solution with a concentration of 140g / l, and then the reaction The system was heated to 85° C. and kept under stirring for 40 minutes; then the reaction system was further heated to 105° C. and reacted for 0.5 hour. The obtained white precipitate was filtered and washed repeatedly to obtain 10 g of filter cake. This 10 g filter cake was added to 30 ml concentration of 0.05M H 3 PO 4 The solution was degelized at 85° C. for 5 hours to obtain a light blue transparent titanium dioxide sol.

[0041] According to the measurement method of Example 1, the white filter cake titanium dioxide crystal form obtained in this example is anatase type; the particle size distribution is narrow and uniform, and the range is 30-80nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com