Integral type catalyst, and preparation method and application thereof

A monolithic catalyst and catalyst technology, applied in chemical instruments and methods, heterogeneous catalyst chemical elements, physical/chemical process catalysts, etc., can solve problems such as difficult separation, solid-liquid separation, and less research on catalysts, and achieve the goal of staying Effects of long time, improved efficiency, and good chemical and biological stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] (1) Cut the honeycomb cordierite into a cylindrical cordierite substrate with a diameter of 30mm and a height of 20mm, soak 16.1g of the substrate in 10wt% nitric acid solution, heat it in a constant temperature water bath at 80°C for 5h, and then wash it with deionized water Wash 4 times, then dry the cordierite in a 70°C drying oven for 4 hours, and finally place the cordierite in a muffle furnace, increase the temperature to 450°C at a rate of 5°C / min, keep the temperature for 5 hours, and then cool down to 80°C Then, it was taken out to obtain 15.5 g of acid-treated cordierite A1 carrier.

[0058] (2) At 20°C, the Ce(NO 3 ) 3 Put 1000 g of the solution into a beaker, place it on a magnetic stirrer, add 27 wt% ammonia water to adjust the pH to 9.0, make it completely precipitate, and filter out the precipitate with a suction filter. Rinse the precipitate several times with deionized water until the pH of the remaining water is 8. Take 100 g of the precipitate and ...

Embodiment 2

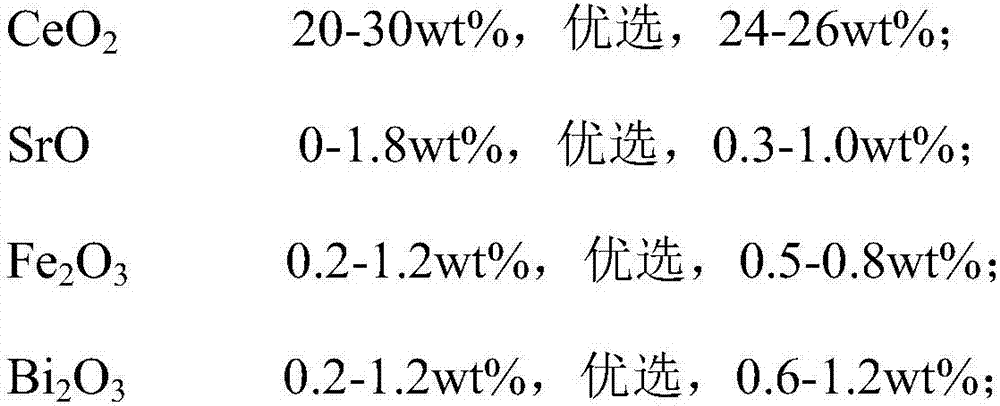

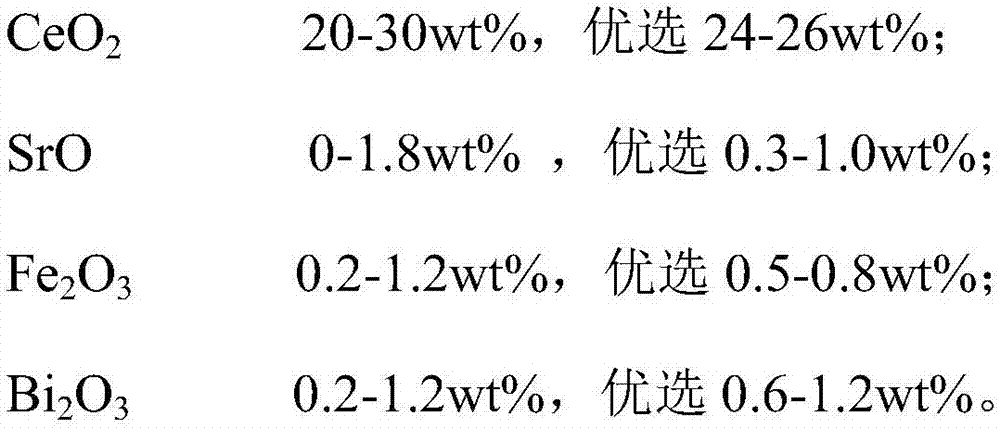

[0063] (1) At 25°C, prepare Ce(NO 3 ) 3 and Sr(NO 3 ) 2 Solution 1000g, wherein Ce(NO 3 ) 3 The mass percentage is 4wt%, Sr(NO 3 ) 2 The percentage content of the solution is 0.4wt%, put it into a beaker, place it on a magnetic stirrer, add 28wt% ammonia water to adjust the pH to 10.0, make it completely precipitate, and filter out the precipitate with a suction filter. Rinse the precipitate several times with deionized water until the pH of the remaining water is 6. Take 100 g of the precipitate and put it into a beaker, add 8 wt% dilute nitric acid at 50°C until the pH is 1, and stir for 2 hours to obtain yellow cerium-strontium sol B2, which is left to stand for 24 hours before use.

[0064] (2) At room temperature, impregnate 15.5g of cordierite A1 in 120g of cerium-strontium sol B2 that was evenly stirred, keep it for 4 minutes, blow off the excess liquid in the channel with a suction ear ball, and then place the cordierite in an oven at 95°C Dry for 35 minutes, r...

Embodiment 3

[0068](1) Cut the honeycomb cordierite into a cylindrical cordierite substrate with a diameter of 30mm and a height of 20mm, soak 16.2g of the substrate in 15wt% nitric acid solution, heat it in a constant temperature water bath at 60°C for 3h, and then wash it with deionized water 6 times, then dry the cordierite in a 90°C drying oven for 2 hours, and finally place the cordierite in a muffle furnace, increase the temperature to 500°C at a rate of 3°C / min, keep the temperature for 3 hours, and then cool down to below 80°C It was taken out to obtain 15.4 g of acid-treated cordierite A2 support.

[0069] (2) At room temperature, immerse 15.4g of cordierite A2 in 140g of cerium-strontium sol B2 that is evenly stirred, keep it for 6 minutes, blow off the excess liquid in the channel with a suction ear ball, and then place the cordierite in an oven at 100°C Dry for 30 minutes, repeat this operation 7 times, and finally place the cordierite in a muffle furnace, raise the temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com