Modification method of ternary cathode material

A positive electrode material and modification technology, applied in the direction of electrical components, battery electrodes, circuits, etc., can solve the problems of oxygen evolution, poisoning of industrial wastewater, uneven doping, etc., to reduce irreversible capacity, prevent agglomeration growth, The effect of improving ion conductance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

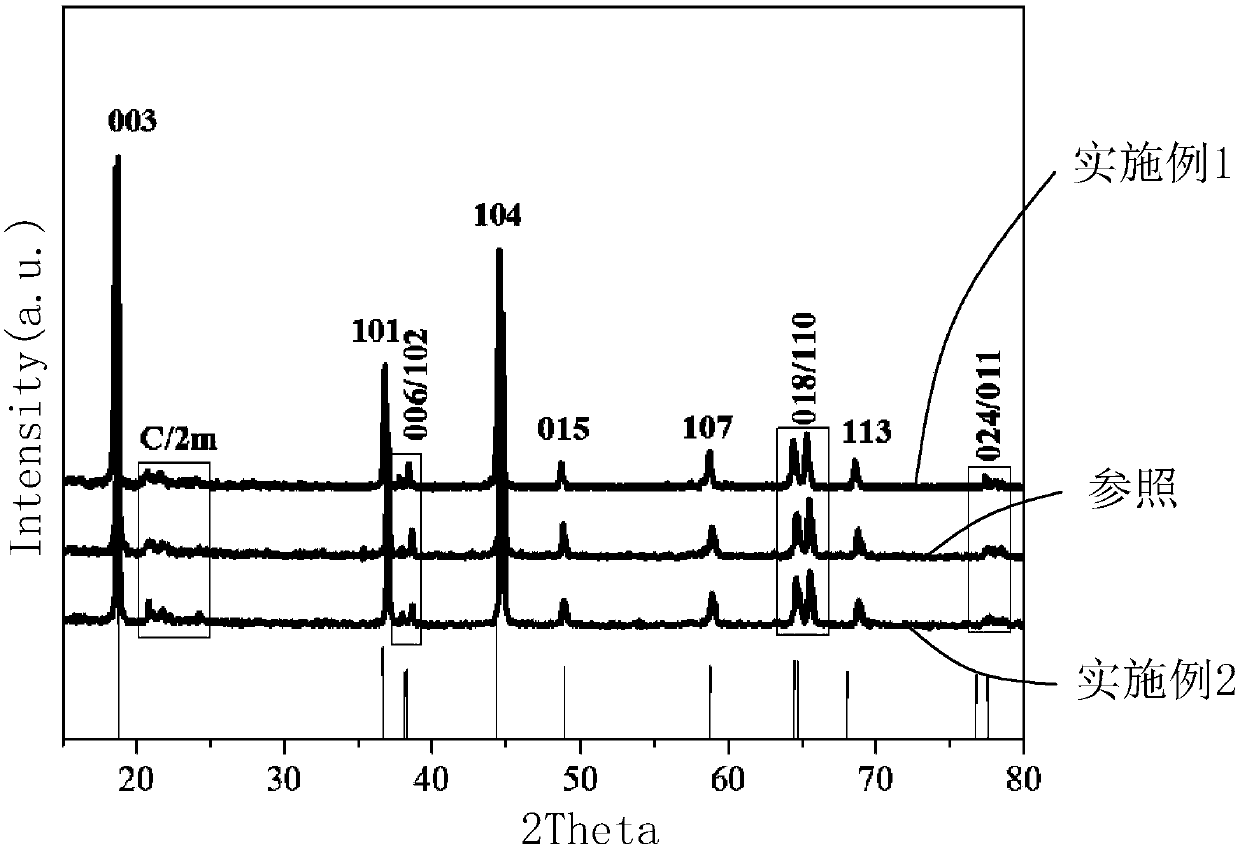

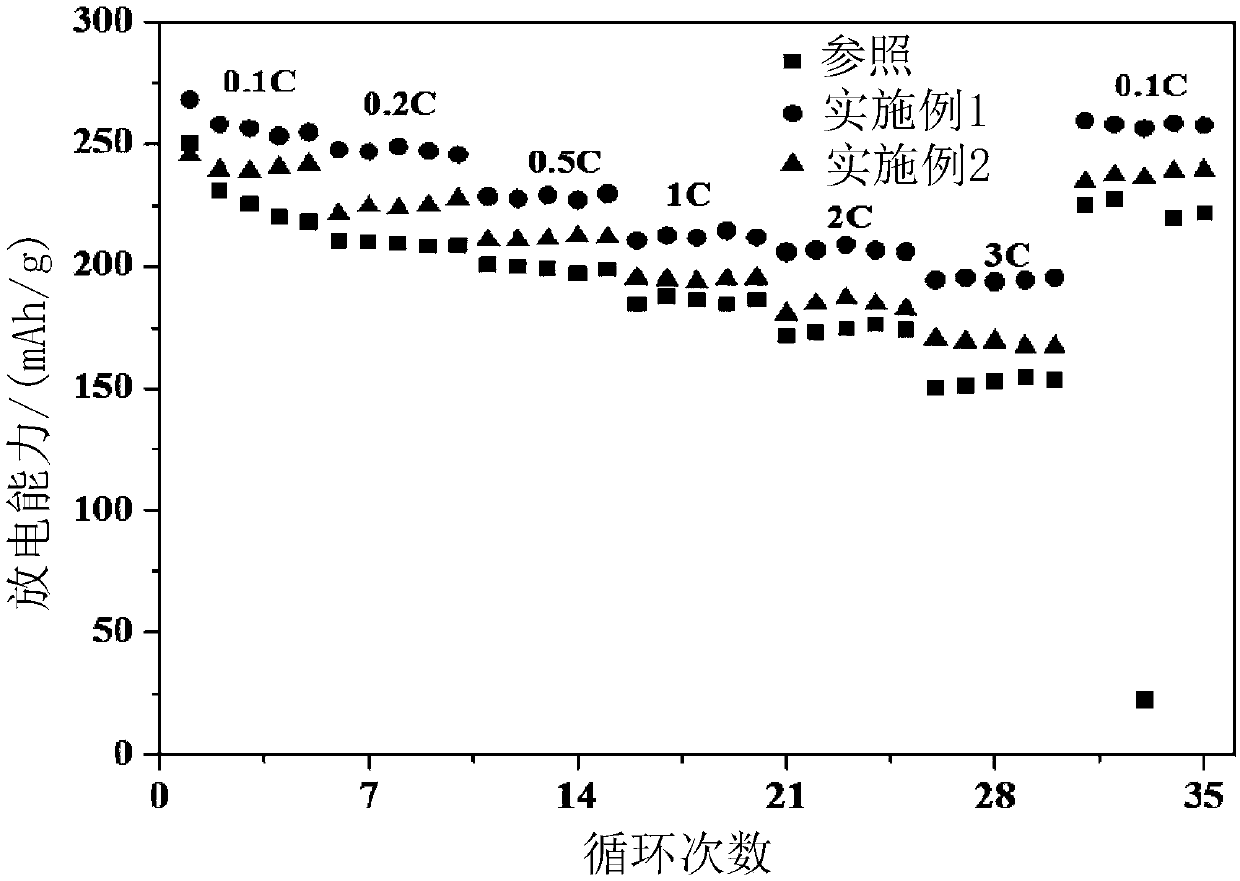

Embodiment 1

[0029] Weigh 0.8g hydroxyethyl cellulose and dissolve it in 50mL water to form a hydroxyethyl cellulose solution. Mix the nickel nitrate solution containing 0.015mol nickel nitrate, the cobalt nitrate solution containing 0.015mol cobalt nitrate and the manganese nitrate solution containing 0.07mol manganese nitrate Add the solution into the hydroxyethyl cellulose solution, add a certain amount of water to dilute to a total metal concentration of 1.5mol / L, and stir for 2 hours. Dissolve 0.14 mol of lithium hydroxide in 40 mL of water to form a lithium hydroxide solution, weigh 20 g of oxalic acid and dissolve it in 100 mL of deionized water at a temperature of 60° C. / min and the rate of addition of 6mL / min are added simultaneously in the hydroxyethyl cellulose solution that is dispersed with nickel nitrate, cobalt nitrate and manganese nitrate to form a mixed solution, and adopt 25% ammoniacal liquor in the dropping process to make the mixed solution The pH is controlled aroun...

Embodiment 2

[0032]Weigh 0.8g hydroxyethyl cellulose and dissolve it in 50mL water to form a hydroxyethyl cellulose solution. Mix the nickel nitrate solution containing 0.015mol nickel nitrate, the cobalt nitrate solution containing 0.015mol cobalt nitrate and the manganese nitrate solution containing 0.07mol manganese nitrate Add the solution into the hydroxyethyl cellulose solution, add a certain amount of water to dilute to a total metal concentration of 1.5mol / L, and stir for 2 hours. Dissolve 0.14 mol of lithium hydroxide in 40 mL of water to form a lithium hydroxide solution, weigh 20 g of oxalic acid and dissolve it in 100 mL of deionized water at a temperature of 60° C. / min and the rate of addition of 6mL / min are added simultaneously in the hydroxyethyl cellulose solution that is dispersed with nickel nitrate, cobalt nitrate and manganese nitrate to form a mixed solution, and adopt 25% ammoniacal liquor in the dropping process to make the mixed solution The pH is controlled around...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com