A kind of high-voltage additive for lithium battery electrolyte, electrolyte and lithium battery

An electrolyte and additive technology, applied in secondary batteries, circuits, electrical components, etc., can solve problems such as shortening battery life and battery performance degradation, and achieve enhanced stability, cycle life and high-temperature storage life, and reduce impedance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

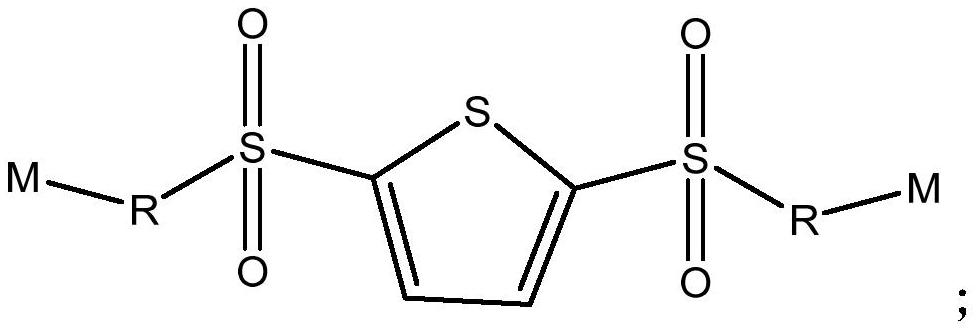

[0035] This embodiment provides a high-voltage additive A for lithium battery electrolyte:

[0036]

[0037] In an argon atmosphere, the environmental index is H 2 O≤0.5ppm, O 2 In the glove box of ≤2.0ppm, the organic solvents ethylene carbonate (EC), propylene carbonate (PC), fluoroethylene carbonate (FEC), and methyl ethyl carbonate (EMC) are prepared according to the mass ratio EC: PC: FEC: EMC=10:15:5:70 for mixing, then add lithium salt LiPF 6 and LiDFOB for dissolution, where LiPF 6 The content of LiDFOB accounts for 10% of the mass ratio of the solution, the content of LiDFOB is 5%, and then the auxiliary additive vinylene carbonate (VC) is added according to the mass fraction 0.5%, and then 1% of the high-voltage additive A is added to prepare the electrolyte. I.

Embodiment 2

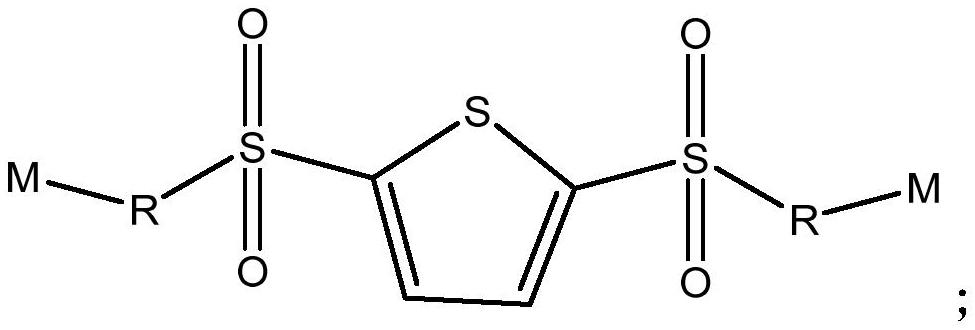

[0039] This embodiment provides a high-voltage additive B for lithium battery electrolyte:

[0040]

[0041] In an argon atmosphere, the environmental index is H 2 O≤0.5ppm, O2 In the glove box of ≤2.0ppm, the organic solvents ethylene carbonate (EC), propylene carbonate (PC), fluoroethylene carbonate (FEC), and methyl ethyl carbonate (EMC) are prepared according to the mass ratio EC: PC: FEC: EMC=10:15:5:70 for mixing, then adding lithium salt LiPF 6 and LiDFOB for dissolution, where LiPF 6 The content of LiDFOB accounts for 10% of the mass ratio of the solution, the content of LiDFOB is 5%, and then the auxiliary additive vinylene carbonate (VC) is added according to the mass fraction 0.5%, and then 1% of the high-voltage additive B is added to prepare the electrolyte. II.

Embodiment 3

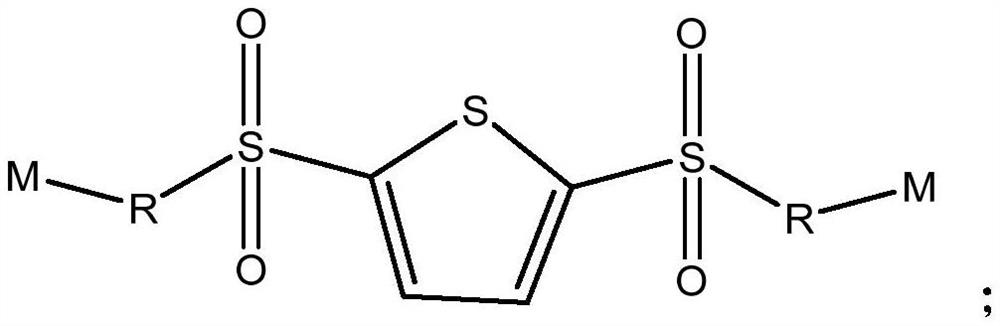

[0043] This embodiment provides a high-voltage additive C for lithium battery electrolyte:

[0044]

[0045] In an argon atmosphere, the environmental index is H 2 O≤0.5ppm, O 2 In the glove box of ≤2.0ppm, the organic solvents ethylene carbonate (EC), propylene carbonate (PC), fluoroethylene carbonate (FEC), and methyl ethyl carbonate (EMC) are prepared according to the mass ratio EC: PC: FEC: EMC=10:15:5:70 for mixing, then adding lithium salt LiPF 6 and LiDFOB for dissolution, where LiPF 6 The content of LiDFOB is 10% of the mass ratio of the solution, the content of LiDFOB is 5%, and then the auxiliary additive vinylene carbonate (VC) is added according to the mass fraction 0.5%, and then 1% of the high-voltage additive C is added to prepare the electrolyte. III.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com