A metal protective layer based on copper oxide nanowires

A copper oxide nanowire, metal protective layer technology, applied in anodizing, coating, anti-corrosion coating and other directions, can solve the problem of accelerated corrosion rate, etc., to enhance catalytic oxidation, reduce porosity, and enhance corrosion resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

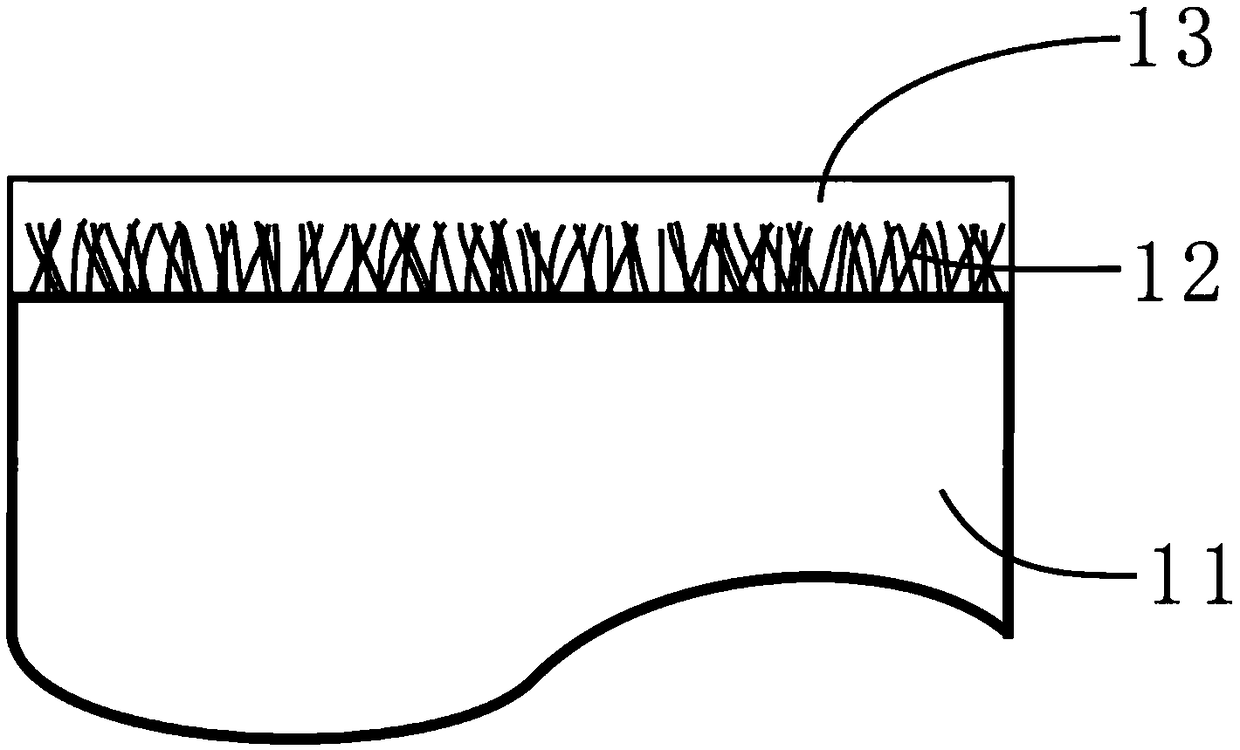

[0030] The preparation process of the metal protective layer is:

[0031] Step 1, cleaning the copper substrate 11

[0032] Cut the copper plate base into the required size, sand it evenly with 400-mesh, 800-mesh, and 1200-mesh sandpaper in turn, ultrasonically clean it in isopropanol for 15 minutes, and then clean it with deionized water.

[0033] Step 2, preparing the middle layer 12

[0034] Place the above-mentioned copper plate substrate after ultrasonic cleaning as an anode, graphite as a cathode, and a KOH solution with a concentration of 2mol / L as an electrolyte, add a small amount of polyvinyl alcohol, and 2 Oxidation was carried out under the current density, and after 30 minutes, the copper plate substrate was taken out, rinsed repeatedly with deionized water, and then dried naturally;

[0035] The above-obtained copper plate substrate was put into a muffle furnace, firstly calcined at 150° C. for 2 h, then calcined at 300° C. for 3 h, and after natural cooling, cop...

Embodiment 2

[0041] The specific steps are as in Example 1, the difference is that the filler in the polyaniline film is Mn 2 O 3 porous microspheres.

[0042] For the metal protective layer obtained in the above steps, the corrosion resistance test is carried out. The test medium is 3.5% NaCl solution, and the sample is sealed with epoxy resin, and the exposed area is 3cm 2 , using the traditional three-electrode system to conduct corrosion resistance tests, it is shown that the metal protection layer of the present application has good corrosion resistance and can effectively protect the metal substrate and reduce the impact of corrosion.

Embodiment 3

[0044] The specific steps are as in Example 1, the difference is that the filler in the polyaniline film is TiO 2 Nanoparticles.

[0045] For the metal protective layer obtained in the above steps, the corrosion resistance test is carried out. The test medium is 3.5% NaCl solution, and the sample is sealed with epoxy resin, and the exposed area is 3cm 2 , using the traditional three-electrode system to conduct corrosion resistance tests, it is shown that the metal protection layer of the present application has good corrosion resistance and can effectively protect the metal substrate and reduce the impact of corrosion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com