Preparation method for natural bone repairing material capable of accelerating osteanagenesis

A technology for repairing materials and natural bone, applied in tissue regeneration, medical science, prosthesis, etc., can solve the problems of artificial bone repair materials such as unsatisfactory compressive strength and elastic modulus, low amount of osteogenesis, lack of osteoinductivity, etc. , to achieve good osteoinductive activity, fast repair, and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

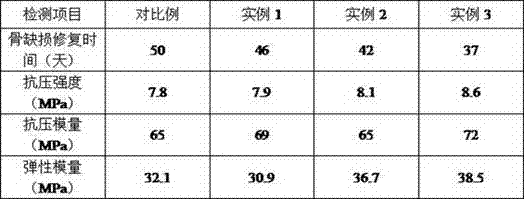

Examples

example 1

[0015] Weigh 1 kg of fresh bovine bone, wash the bovine bone with deionized water for 3 times, then add the washed bovine bone to 2L of deionized water, cook at 95°C for 3 hours, take out the bovine bone after cooling to room temperature, and remove the bovine bone with a scraper Surface soft tissue, get pretreated bovine bone, soak the pretreated bovine bone in 2L of 4% sodium hydroxide solution at 60°C for 6 hours, take out the bovine bone and transfer it to 1L of 30% hydrogen peroxide Soak for 10 hours, take out the bovine bones, and get the impurity-removed bovine bones, then soak and clean the impurity-removed bovine bones with 1L of absolute ethanol for 1 hour, then transfer them to a blast drying oven, and dry them at 105°C to constant weight. The final product is put into a pulverizer and pulverized, passed through a 20-mesh sieve to obtain crude calcium phosphate, then put the crude calcium phosphate into a muffle furnace, heat up to 500°C at a rate of 5°C / min, and aft...

example 2

[0017] Weigh 1 kg of fresh bovine bone, wash the bovine bone with deionized water 4 times, then add the washed bovine bone to 2L of deionized water, cook at 98°C for 4 hours, take out the bovine bone after cooling to room temperature, and remove the bovine bone with a scraper Surface soft tissue, get pretreated bovine bone, soak the pretreated bovine bone in 2L of 4% sodium hydroxide solution at 65°C for 7 hours, take out the bovine bone and transfer it to 1L of 30% hydrogen peroxide Soak for 11 hours, take out the bovine bones to get the impurity-removed bovine bones, then soak and clean the impurity-removed bovine bones with 1L of absolute ethanol for 1 hour, then transfer them to a blast drying oven, and dry them at 108°C to constant weight. The final product is put into a pulverizer and pulverized, passed through a 20-mesh sieve to obtain crude calcium phosphate, then put the crude calcium phosphate into a muffle furnace, heat up to 550°C at a rate of 8°C / min, and after cal...

example 3

[0019]Weigh 2kg of fresh bovine bones, wash the bovine bones with deionized water for 5 times, then add the washed bovine bones to 3L of deionized water, cook at 100°C for 5 hours, take out the bovine bones after cooling to room temperature, and remove the bovine bones with a scraper Surface soft tissue, get pretreated bovine bone, soak the pretreated bovine bone in 3L of 4% sodium hydroxide solution at 70°C for 8 hours, take out the bovine bone and transfer it to 2L of 30% hydrogen peroxide Soak for 12 hours, take out the bovine bone, and get the impurity-removed bovine bone, then soak and clean the impurity-removed bovine bone with 2L of absolute ethanol for 2 hours, then transfer it to a blast drying oven, dry it at 110°C to constant weight, and then dry it The final product is put into a pulverizer and pulverized, passed through a 20-mesh sieve to obtain crude calcium phosphate, then put the crude calcium phosphate into a muffle furnace, heat up to 600°C at a rate of 10°C / m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com