A kind of single column heterogeneous phase azeotropic rectification separates the method of aniline and ethylene glycol azeotrope

A technology of azeotropic distillation and azeotropic distillation column, which is applied in chemical instruments and methods, preparation of organic compounds, purification/separation of amino compounds, etc., and can solve problems such as difficult separation, low product purity, and high process energy consumption , to achieve the effect of low equipment investment cost, simple process and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

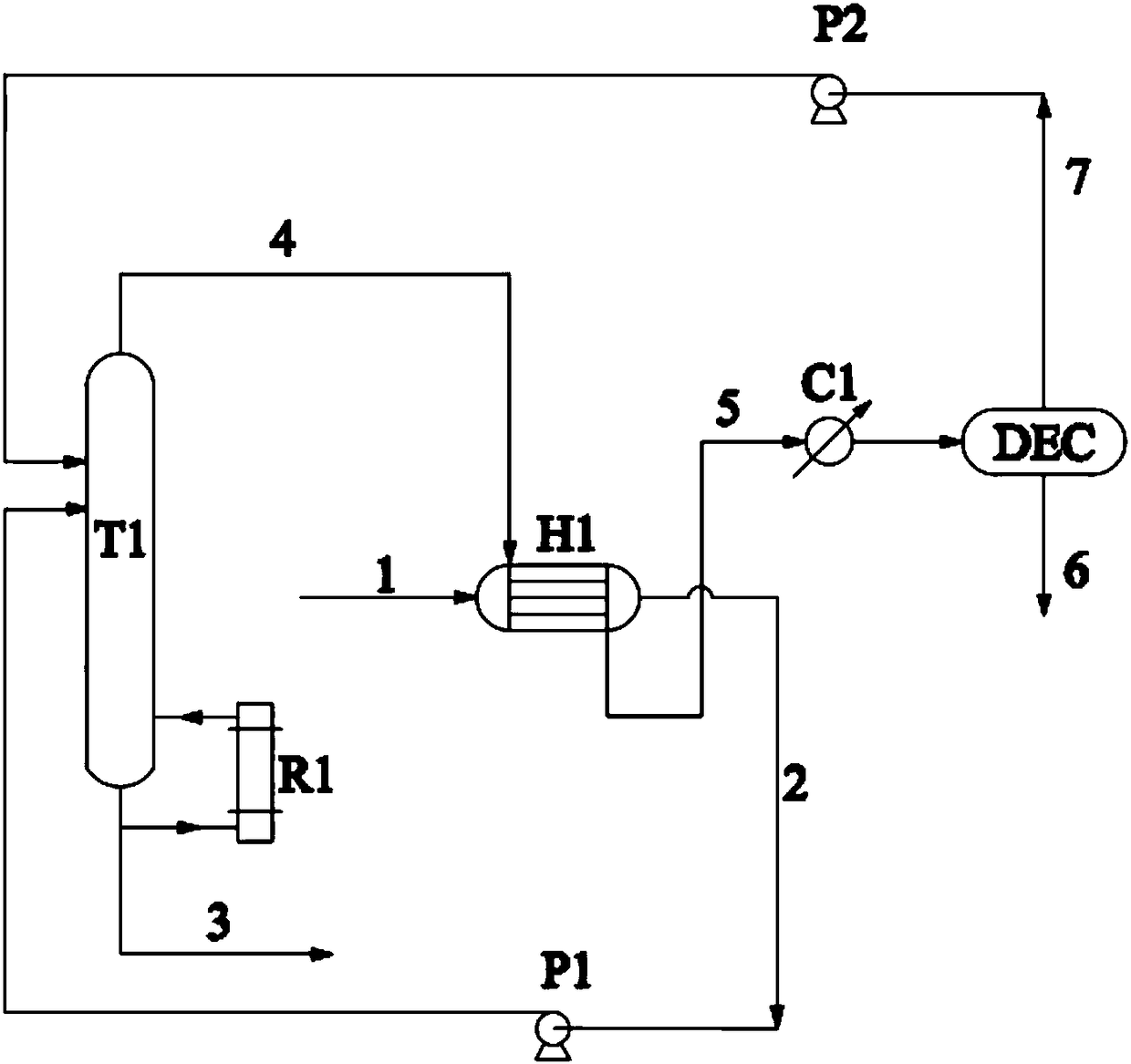

Embodiment 1

[0037] In the azeotropic rectification column whose operating pressure is 1atm (absolute pressure) and the number of trays is 15 plates, the aniline-ethylene glycol mixture with 1000kg aniline mass fraction accounting for 60% is preheated on the 5th tray Entering the tower, the entrainer cyclohexane circulates into the tower from the first tray, the temperature at the top of the tower is 78.2°C, and the temperature at the bottom of the tower is 180.0°C; after heat exchange by the heat exchanger, ethylene glycol is partially condensed, and then The temperature of further condensation via the auxiliary condenser is 30°C. The mass fraction of aniline after separation is 99.98%, and the yield is 99.95%; the mass fraction of ethylene glycol after separation is 99.97%, and the yield is 99.93%.

Embodiment 2

[0039] Be 1atm (absolute pressure) at operating pressure, in the azeotropic rectification column that plate number is 18 plates, 1000kg aniline mass fraction accounts for 65% aniline-ethylene glycol mixed solution after preheating in the 6th tower The plate enters the tower, and the entrainer cyclohexane circulates into the tower from the first plate, the temperature of the top of the tower is 79.5°C, and the temperature of the bottom of the tower is 181.0°C; after heat exchange by the heat exchanger, the ethylene glycol is partially condensed, The further condensation temperature is 30°C through the auxiliary condenser. The mass fraction of aniline after separation is 99.96%, and the yield is 99.95%; the mass fraction of ethylene glycol after separation is 99.97%, and the yield is 99.95%.

Embodiment 3

[0041]In the azeotropic rectification tower whose operating pressure is 1atm (absolute pressure) and the number of trays is 20 plates, the aniline-ethylene glycol mixed solution accounting for 70% of the mass fraction of 1000kg aniline is preheated in the 7th tower The plate enters the tower, and the entrainer cyclohexane circulates into the tower from the first plate, the temperature of the top of the tower is 81.0°C, and the temperature of the bottom of the tower is 182.0°C; after heat exchange by the heat exchanger, the ethylene glycol is partially condensed, The further condensation temperature is 30°C through the auxiliary condenser. The mass fraction of aniline after separation is 99.98%, and the yield is 99.98%; the mass fraction of ethylene glycol after separation is 99.97%, and the yield is 99.98%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com