Packing contained composite material, sheet and circuit board containing same

A composite material and sheet technology, applied in the direction of circuit substrate materials, printed circuits, printed circuit components, etc., can solve the problems of small molecular weight, complex use, low solid content and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

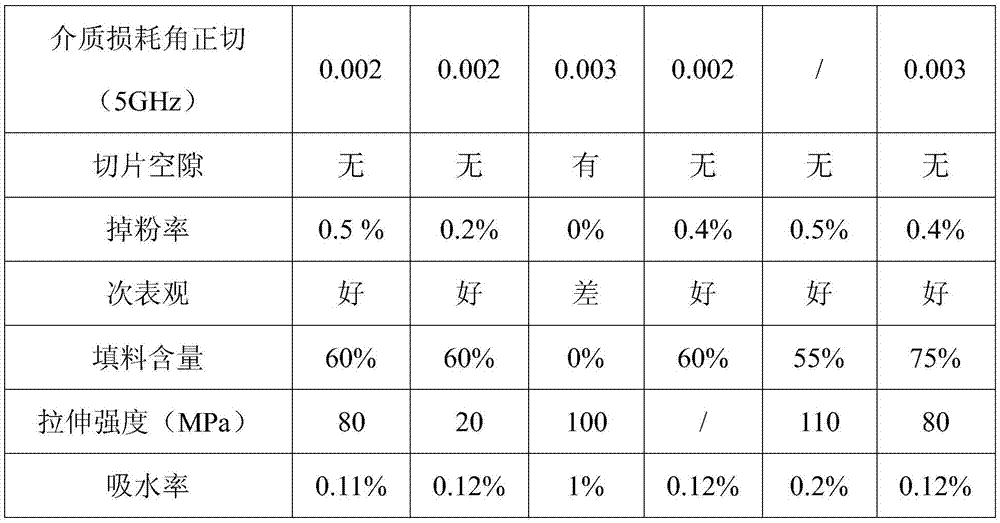

Examples

preparation example

[0103] The liquid crystal polymer fiber non-woven fabric was prepared by the melt-blown method. That is, liquid crystal polymer resin (Polyplastics Co., Ltd., LAPREOS) is melted with a single-screw extruder (caliber 30mm, L / D = 24), and then introduced into a special mold with a flow adjustment structure and a heated air introduction structure, and then from the mold The spinning nozzle on the top (has 10 circular molten resin discharge holes (inner diameter 400 μm) and slit-shaped gas discharge holes (width 1 mm), these molten resin discharge holes are arranged in a row with an effective width of 5 cm, and the gas The ejection holes can eject heated air in parallel with the arrangement direction, thereby applying tensile stress to the molten resin.) and stretched to form fibers. And the fibers are collected on the surface of the film substrate to form a non-woven fabric to be finished with a width of about 5 cm. Then, the nonwoven fabric to be finished is passed between a pa...

Embodiment 1

[0111] The sheet-like liquid crystal polymer fiber non-woven fabric (average fiber diameter is 2.6 μ m, unit weight is 22 g / m 2 , thickness 50 μm, porosity about 75%, pore diameter between fibers is about 15 μm), in spherical silica powder slurry (spherical silica powder particle size D90 is 3 μ m, D50 is about 1 μ m, slurry is 70% methyl ethyl ketone Suspension), then pass through a gap of 0.1mm, scrape off the surface slurry, dry off the solvent, then soak again, pass through the gap and dry off the solvent, repeat three times. Dry the non-woven fabric impregnated with slurry in a blast oven at 155°C for 5 minutes, beat the dried non-woven fabric to remove the filler on the surface. Then laminate 3 sheets of non-woven fabrics containing fillers, and cover both sides with polytetrafluoroethylene film as a release film. At 350 ° C, in a vacuum environment, heat press in an electric heating press for 1 hour at a pressure of 6 MPa to obtain a filler-containing Liquid crystal re...

Embodiment 2

[0117] The sheet-like liquid crystal polymer fiber non-woven fabric (average fiber diameter is 2.6 μ m, unit weight is 22 g / m 2 , thickness 50 μm, porosity about 75%, pore diameter between fibers is about 15 μm), in spherical silica powder slurry (spherical silica powder particle size D90 is 3 μ m, D50 is about 1 μ m, slurry is 70% methyl ethyl ketone Suspension), then pass through a gap of 0.1mm, scrape off the surface slurry, dry off the solvent, then soak again, pass through the gap and dry off the solvent, repeat three times. Dry the non-woven fabric impregnated with slurry in a blast oven at 155°C for 5 minutes, beat the dried non-woven fabric to remove the filler on the surface. Then laminate 3 sheets of non-woven fabric, cover both sides with 18 μm copper foil, and heat press in an electric heating press for 1 hour at 350° C. under a vacuum environment with a pressure of 6 MPa to obtain a liquid crystal polymer resin circuit substrate containing fillers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com