Ceramic Particle Composite Resin-Based Thermal Decay Resistance Friction Material and Preparation Method

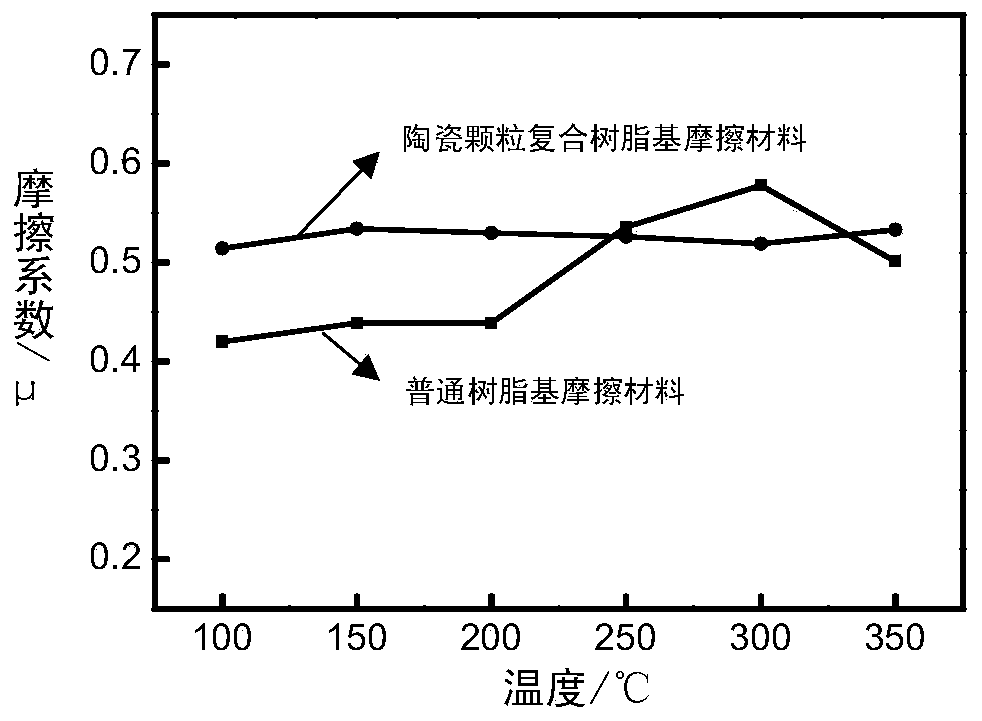

A technology of ceramic particles and friction materials, which is applied to friction linings, chemical instruments and methods, mechanical equipment, etc. Stable coefficient, stable friction coefficient, good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

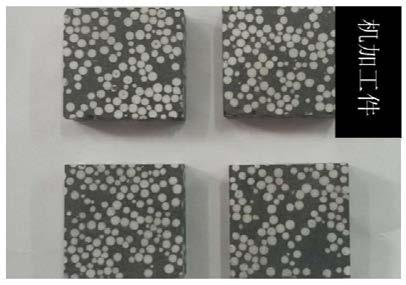

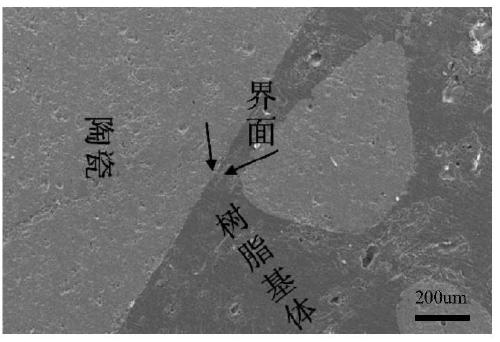

Embodiment 1

[0032] Cashew nut shell oil modified phenolic resin was selected as the binder, and its mass fraction was 35%; aramid fiber and glass fiber were mixed as the reinforcing component, and the mass fractions of the two were 5% and 5% respectively; barite As a space filler to reduce production costs, its mass fraction is 40%; add 5% aluminum powder to increase the overall thermal conductivity of the material; add 5% graphite to reduce the wear of ceramic particles on the pair; add 5% vermiculite It is used to reduce the noise that may be generated during the friction process of the material. Then put the above components in a high-speed mixer and mix them for 3 minutes to form evenly mixed resin-based friction material powder. Choose irregular silicon oxide ceramic particles as reinforced ceramics, first sieve the ceramic particles, select particles between 1-1.5mm, the amount of ceramic particles is related to the amount of resin, add 60g of ceramic particles (ceramic particles) p...

Embodiment 2

[0037]The nitrile rubber modified phenolic resin is selected as the binder, and its mass fraction is 30%; the mixture of chopped carbon fiber and glass fiber is selected as the reinforcing component, and the mass fractions of the two are 5% and 5% respectively; silica fume Stone is used as a space filler with a mass fraction of 30%; 5% aluminum powder and 5% copper powder are added to increase the overall thermal conductivity of the material; 5% graphite and 5% molybdenum disulfide are added to improve the lubrication of the material The effect is to reduce the wear of the material on the pair; add 10% vermiculite to reduce the noise that the material may produce during the friction process. Then put the above components in a high-speed mixer and mix them for 5 minutes to form evenly mixed resin-based friction material powder. Select spherical alumina ceramic particles as composite ceramics, sieve the ceramic particles, select particles between 1.5-2mm, the amount of ceramic p...

Embodiment 3

[0042] Cashew nut shell oil modified phenolic resin was selected as the binder with a mass fraction of 10%; a mixture of chopped carbon fibers and carbon nanotubes was selected as a reinforcing component, and the mass fractions of the two were 5% and 5% respectively; silicon Limestone is used as a space filler with a mass fraction of 50%; 5% aluminum powder and 5% copper powder are added to increase the overall thermal conductivity of the material; 5% graphite and 5% molybdenum disulfide are added to improve material lubrication Sex; add 10% vermiculite to reduce the noise that the material may produce during friction. Then put the above components in a high-speed mixer and mix them for 5 minutes to form evenly mixed resin-based friction material powder. Choose irregular alumina ceramic and silica ceramic hybrid particles as composite ceramics, sieve the ceramic particles, select 2mm particles, the amount of ceramic particles depends on the amount of resin, add 30g of the abov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com