Heat-resistant high-niobium austenite steel and preparation method thereof

A technology of austenitic heat-resistant steel and content, applied in the field of high-temperature metal structural materials, can solve the problems of insufficient high-temperature strength, poor structural stability, affecting the safe operation of power stations, etc., to reduce grain boundary interface energy and improve grain boundary bonding. strength, the effect of improving the resistance to steam oxidation and flue gas corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

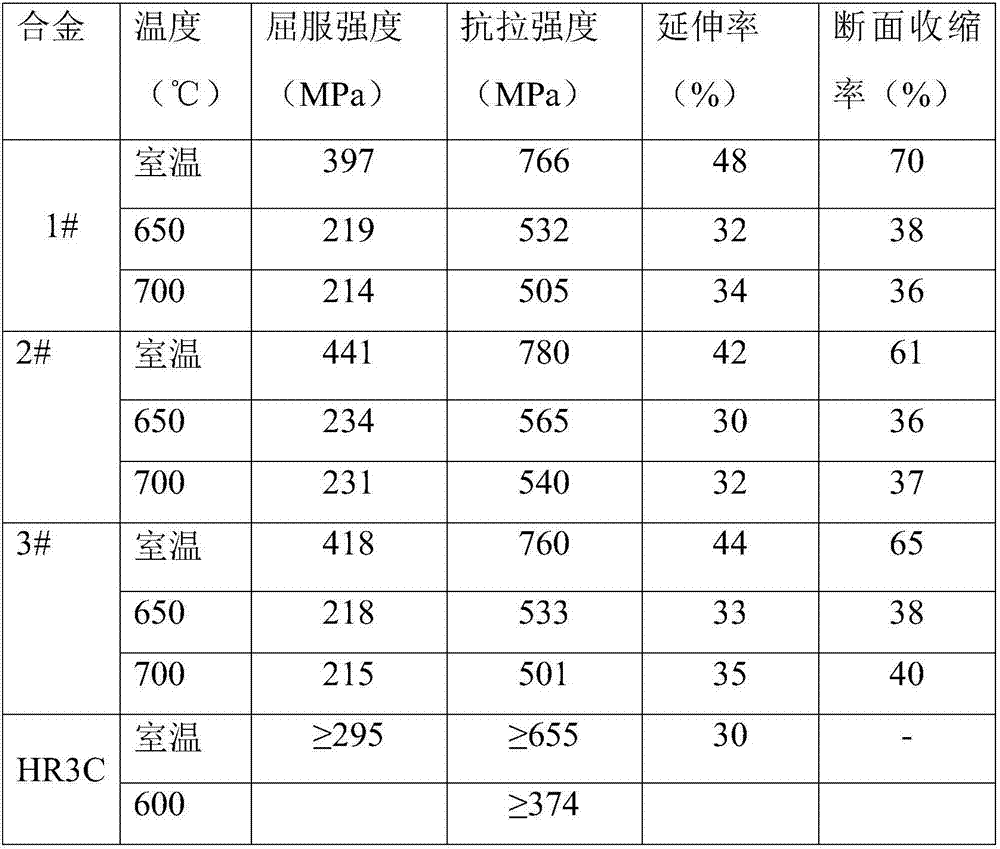

[0039] The tensile properties at room temperature of Example 1#-3# alloys are much higher than the HR3C index in the GB5310-2008 standard. As the temperature increases, the strength of austenitic heat-resistant steel will decrease. At 650°C and 700°C, the tensile strengths of the alloys of Examples 1#-3# are much higher than 374MPa of HR3C at 600°C. It is shown that the example alloys have excellent room temperature and high temperature strength.

[0040] The tensile properties of table 2 embodiment alloy and HR3C

[0041]

[0043] After the alloys of Examples 1#-3# were exposed to heat at 650°C for 500 hours, their impact toughness at room temperature is shown in Table 3, all of which are greater than 50J / cm 2 , higher than HR3C (45J / cm 2 ) above 10%. It shows that the alloy of the present invention has excellent impact toughness.

[0044] Table 3 Room temperature impact properties of the alloys of the examples and HR3C exposed to heat a...

Embodiment 4-7

[0048] Table 4 shows the chemical composition of Examples 4, 5, 6 and 7 of the present invention. Alloys 4#-6# used in the test are austenitic alloys with high niobium content in Examples 4, 5, 6 and 7 of the present invention.

[0049] The chemical composition (% by weight, balance is Fe) of the embodiment of the present invention 4-7 of table 4

[0050] alloy 4# 5# 6# 7# Ni 23 22 25 19 Cr 21 23 20 25 mn 0.5 0.3 1.0 0.8 Nb 2.5 3.5 4 2 Si 0.1 0.6 0.75 0.5 N 0.15 0.25 0.3 0.1 C 0.05 0.15 0.04 0.08 B 0.001 0.002 0.003 0.001 Zr 0.002 0.003 0.002 0.001 P 0.015 0.01 0.022 0.03 co 6.0 1.0 2.0 3.0 V 0.25 0 0.01 0.1 Ce <0.005

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com