Method for preparing ionic liquid/transition metal disulphide gas separating membrane and application thereof

A gas separation membrane, ionic liquid technology, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve problems such as poor stability, and achieve the effects of increasing stability, improving separation performance, and significantly gas separation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 1) Under the protection of argon, add 0.2g molybdenum disulfide powder to 2ml n-butyllithium n-hexane solution (15%), stir and react at room temperature for 48h, wash and dry thoroughly with hexane to obtain lithium intercalated molybdenum disulfide Powder LixMoS 2 .

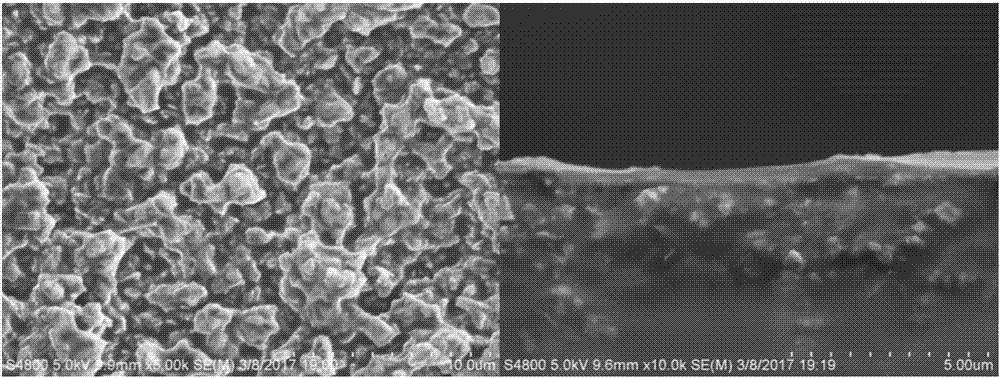

[0021] 2) Add 0.02g LixMoS 2 Add to 2mL[Bmim][BF 4 ], mixed in an ice-water bath for 1 h to obtain MoS 2 [Bmim][BF 4 ]Dispersions. Under the negative pressure of 90KPa, 1ml MoS 2 [Bmim][BF 4 ] Suction filtration of the dispersion onto the inorganic alumina porous membrane to prepare [Bmim][BF 4 ] / MoS 2 Gas separation membranes, see figure 1 . figure 1 Shown [Bmim][BF 4 ] / MoS 2 The surface of the gas separation membrane is dense, and the film is continuous without cracks, so it can be seen that the two materials form a compact composite material. The diameter of the inorganic alumina porous membrane is 2.5cm, the pore diameter is 200nm, and the porosity is 25-50%;

[0022] 3) to the prepared ...

Embodiment 2

[0024] 1) Under the protection of argon, add 0.2g of tungsten disulfide powder to 2ml of n-butyllithium n-hexane solution (15%), heat and stir at 60°C for 48h, wash and dry thoroughly with hexane to obtain lithium intercalation disulfide Tungsten powder LixWS 2 .

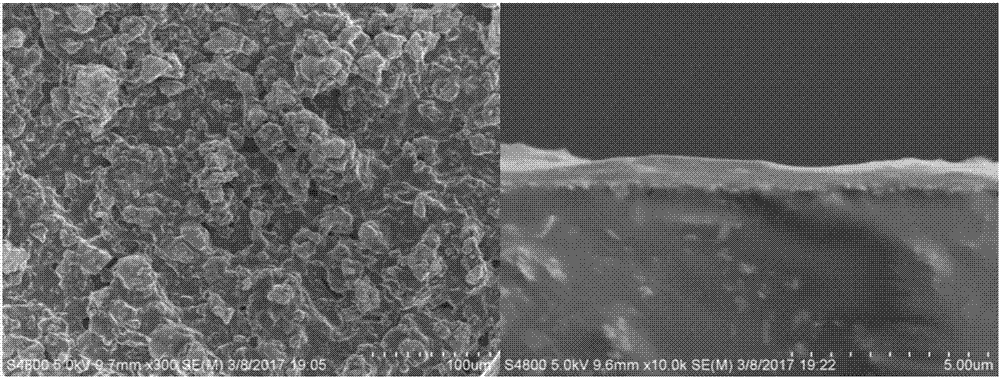

[0025] 2) Add 0.02g LixWS 2 Add to 2mL[Bmim][BF 4 ], mixed in an ice-water bath for 1 h to obtain WS 2 [Bmim][BF 4 ]Dispersions. Under the negative pressure of 90KPa, 1ml WS 2 [Bmim][BF 4 ] Suction filtration of the dispersion onto the inorganic alumina porous membrane to prepare [Bmim][BF 4 ] / WS 2 Gas separation membranes, see figure 2 . figure 2 Shown [Bmim][BF 4 ] / WS 2 The surface of the gas separation membrane is dense, and the film is continuous without cracks, so it can be seen that the two materials form a compact composite material. The diameter of the inorganic alumina porous membrane is 2.5cm, the pore diameter is 200nm, and the porosity is 25-50%;

[0026]3) to the prepared [Bmim][BF 4 ] / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com