A kind of polyaluminum chloride waste slag dry-mixed mortar and preparation method thereof

A technology of polyaluminium chloride and dry-mixed mortar, which is applied in the direction of solid waste management, sustainable waste treatment, and climate sustainability. The activity can not be well utilized and other problems, to achieve the effect of improving bleeding and segregation performance, good water retention and strong adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

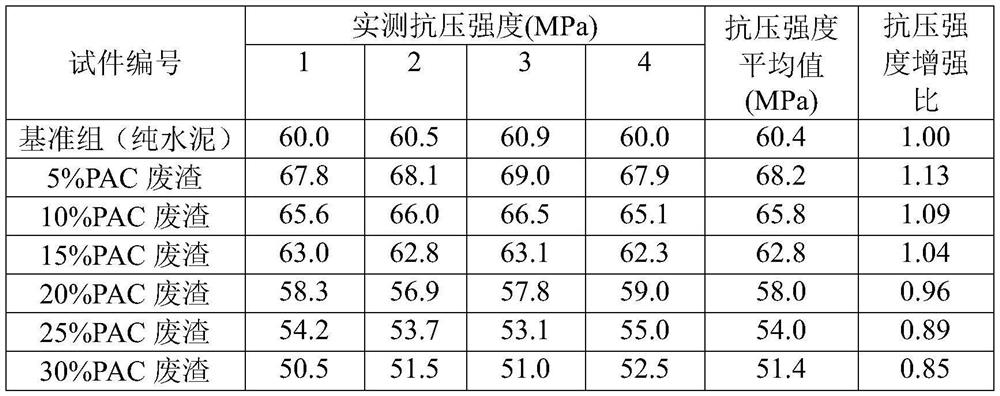

Method used

Image

Examples

Embodiment 1

[0040] A polyaluminum chloride waste slag dry-mixed mortar, calculated in parts by mass, comprising the following raw materials: 8 parts of thermally activated polyaluminum chloride waste slag (calcined at a high temperature of 800° C. for 2 hours), 23 parts of PO42.5 ordinary Portland cement, medium sand 55 parts, 4 parts fly ash, 15 parts water, 0.05 part defoamer, 0.22 part water reducing agent.

[0041] The preparation method of polyaluminum chloride waste residue dry-mixed mortar is as follows: heat-activated polyaluminum chloride waste residue, PO42.5 ordinary Portland cement, fly ash, medium sand and defoamer are sequentially added to a mortar mixer, and stirred evenly ( 1-3min) to obtain a premix; then add the water reducing agent and water to the mortar mixer in turn, and stir evenly (1-5min) to obtain polyaluminum chloride waste slag dry-mixed mortar S-1.

Embodiment 2

[0043] A polyaluminum chloride waste slag dry-mixed mortar, calculated in parts by mass, comprising the following raw materials: 8 parts of thermally activated polyaluminum chloride waste slag (calcined at a high temperature of 800° C. for 2 hours), 23 parts of PO42.5 ordinary Portland cement, medium sand 55 parts, 4 parts fly ash, 15 parts water, 5 parts styrene-acrylic emulsion, 0.05 part defoamer, 0.20 part water reducing agent.

[0044] The preparation method of polyaluminum chloride waste residue dry-mixed mortar is as follows: adding heat-activated polyaluminum chloride waste residue, PO42.5 ordinary Portland cement, medium sand, fly ash and defoamer into a mortar mixer in turn, and stirring them evenly ( 1-3min) to obtain a premix; then add the styrene-acrylic emulsion, water reducing agent and water to the mortar mixer in turn, and stir evenly (1-5min) to obtain polyaluminum chloride waste residue dry-mixed mortar S-2.

Embodiment 3

[0046] A polyaluminum chloride waste slag dry-mixed mortar, calculated in parts by mass, comprising the following raw materials: 8 parts of thermally activated polyaluminum chloride waste slag (calcined at a high temperature of 800° C. for 2 hours), 23 parts of PO42.5 ordinary Portland cement, medium sand 55 parts, 4 parts of fly ash, 15 parts of water, 8 parts of styrene-acrylic emulsion, 0.05 part of defoamer, and 0.20 part of water reducing agent.

[0047] The preparation method of polyaluminum chloride waste residue dry-mixed mortar is as follows: adding heat-activated polyaluminum chloride waste residue, PO42.5 ordinary Portland cement, medium sand, fly ash and defoamer into a mortar mixer in turn, and stirring them evenly ( 1-3min) to obtain a premix; then add the styrene-acrylic emulsion, water reducing agent and water into the mortar mixer in turn, and stir evenly (1-5min) to obtain polyaluminum chloride waste residue dry-mixed mortar S-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com