High-temperature ceramic organosilicon-phenolic epoxy anticorrosive paint and preparation method thereof

A technology of phenolic epoxy and high-temperature ceramics, which is applied in the field of coatings, can solve the problems of inability to meet the corrosion protection requirements of metal substrates, low adhesion of metal substrates, and poor corrosion resistance, and achieve improved interface compatibility and improved Effect of ceramicization and improvement of salt spray resistance time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

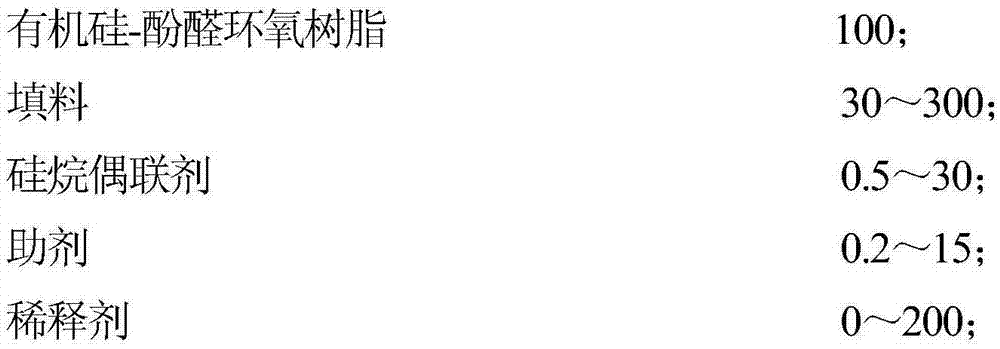

Method used

Image

Examples

Embodiment 1

[0039] Add 100 grams of amino-terminated methyl silicone resin, 1000 grams of epoxy equivalent 185 to 195 (g.mol) in the reaction device -1 ) phenol-type novolac epoxy resin, 5 grams of tetrabutyl titanate, and 3000 grams of acetone were reacted at room temperature for 12 hours to prepare a silicone-novolac epoxy resin, and the acetone was distilled off and sealed for storage.

[0040] Put 100 grams of silicone-phenolic epoxy resin, 60 grams of low-melting glass, 20 grams of silicon dioxide, 50 grams of organic montmorillonite, 100 grams of asbestos powder, 70 grams of vermiculite powder, 30 grams of 3-shrink Glyceryl ether oxypropyl triethoxysilane, 0.05 g of defoamer, 0.05 g of leveling agent, 0.05 g of thickener, 0.05 g of adhesion promoter, 21 g of xylene, and 7 g of n-butanol are evenly mixed by stirring Afterwards, use paint grinding equipment to process for 120 minutes, filter through a 100-mesh screen to obtain component A of the paint, and pour it into a can for stora...

Embodiment 2

[0042] Add 100 grams of hydroxyl-terminated phenyl silicone resin, 5 grams of epoxy equivalent 215-230 (g.mol -1 ) phenol novolac epoxy resin and 0.05 g of dibutyltin dilaurate were reacted at 200° C. for 0.5 hour to prepare a silicone-novolak epoxy resin and seal it for storage.

[0043]In a clean container, 100 grams of silicone-phenolic epoxy resin, 10 grams of low-melting glass, 10 grams of silicon dioxide, 10 grams of organic montmorillonite, 0.5 grams of 3-glycidyl etheroxypropyl trimethoxysilane, 5 grams of antioxidant, 5 grams of anti-skinning agent, and 5 grams of leveling agent are stirred evenly and mixed, then treated with paint grinding equipment for 10 minutes, filtered through a 120-mesh screen to obtain component A of the paint, and poured into a can for storage . Then add 1 gram of triethylenetetramine to component A of the paint and stir evenly, then apply the paint on the surface of the metal test piece with a brush, and cure it at room temperature for one ...

Embodiment 3

[0045] Add the methyl organosilicon resin of 100 gram terminal ethoxy groups, 50 gram epoxy equivalents 176-181 (g.mol -1 ) phenol novolac epoxy resin, 0.5 g of tetraisopropyl titanate, and 180 g of cyclohexanone were reacted at 50° C. for 12 hours to prepare a silicone-novolac epoxy resin, and the cyclohexanone was distilled off and sealed for storage.

[0046] Put 100 grams of silicone-phenolic epoxy resin, 30 grams of low melting point glass, 8 grams of silicon dioxide, 50 grams of organic montmorillonite, 10 grams of asbestos powder, 10 grams of vermiculite powder, 13 grams of 3-shrink Glyceryl ether oxypropylmethyl dimethoxysilane, 0.05g defoamer, 0.05g leveling agent, 0.05g thickener, 0.05g adhesion promoter, 10g isopropanol, 5g butyl acetate, After mixing evenly, use paint grinding equipment for 60 minutes, and filter through a 180-mesh screen to obtain component A of the paint, which is poured into cans for storage. Then add 12 grams of tetraethylenepentamine to compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com