High-tenacity waterproof coiled material and preparation method

A waterproofing membrane, high-toughness technology, applied in chemical instruments and methods, building insulation materials, lamination and other directions, can solve the problems affecting the waterproof performance and strength of the waterproofing membrane, the poor deformation resistance of the membrane, and the inability to meet the requirements of use, etc. problem, to achieve the effect of good toughness and environmental stability, good adhesion and good environmental stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

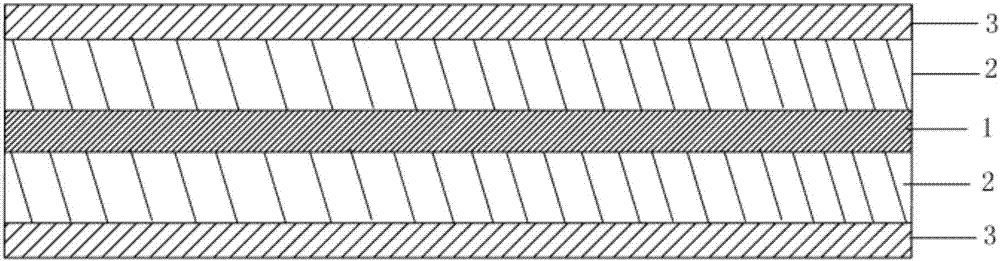

[0027] Such as figure 1 As shown, the present invention relates to a high-toughness waterproof roll material, the waterproof roll material includes a base material layer 1, the upper and lower surfaces of the base material layer are respectively provided with a self-adhesive waterproof layer 2, and the self-adhesive waterproof layer 2 The surface is respectively provided with an isolation protection layer 3 . Wherein, the base material layer 1 is an alkaline glass fiber mat layer, the self-adhesive waterproof layer 2 is polymer modified asphalt, and the isolation protection layer 3 is a PE film.

[0028] The polymer modified asphalt layer comprises the following components by weight fraction: 40 parts of asphalt matrix, 3 parts of SBS, 8 parts of graphene / natural rubber nanocomposite material, 5 parts of natural rubber, 3 parts of plasticizer, modified 8 parts of agent, 15 parts of filler, 3 parts of anti-aging agent, 2 parts of anti-peeling agent, 5 parts of softener, 3 part...

Embodiment 2

[0035] The invention relates to a high-toughness waterproof coiled material. The waterproof coiled material includes a base material layer. The upper and lower surfaces of the base material layer are respectively provided with self-adhesive waterproof layers, and the surfaces of the self-adhesive waterproof layers are respectively provided with isolation protection. layer. Wherein, the base material layer is an alkaline glass fiber felt layer, the self-adhesive waterproof layer is a polymer modified asphalt, and the isolation protection layer is a PE film.

[0036] The polymer modified asphalt layer comprises the following components by weight fraction: 30 parts of asphalt matrix, 1 part of SBS, 5 parts of graphene / natural rubber nanocomposite material, 1 part of natural rubber, 2 parts of plasticizer, modified 5 parts of agent, 10 parts of filler, 1 part of anti-aging agent, 1 part of anti-peeling agent, 2 parts of softener, 1 part of toughening agent, 1 part of stabilizer, a...

Embodiment 3

[0043] The invention relates to a high-toughness waterproof coiled material. The waterproof coiled material includes a base material layer. The upper and lower surfaces of the base material layer are respectively provided with self-adhesive waterproof layers, and the surfaces of the self-adhesive waterproof layers are respectively provided with isolation protection. layer. Wherein, the base material layer is an alkaline glass fiber felt layer, the self-adhesive waterproof layer is a polymer modified asphalt, and the isolation protection layer is a PE film.

[0044] The polymer modified asphalt layer comprises the following components by weight fraction: 50 parts of asphalt matrix, 5 parts of SBS, 10 parts of graphene / natural rubber nanocomposite material, 10 parts of natural rubber, 5 parts of plasticizer, modified 10 parts of agent, 20 parts of filler, 5 parts of anti-aging agent, 3 parts of anti-peeling agent, 6 parts of softener, 5 parts of toughening agent, 3 parts of stab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com