Method for resolving titanium base denitration catalyst and detection method for resolving solution

A denitrification catalyst, titanium-based technology, applied in the detection of digestion solution and the field of digestion of titanium-based denitrification catalysts, can solve the problems of unseen preparation methods and detection methods, and achieve low reagent blank background, low detection limit, and interference effects The effect of few factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of the digestion solution of the present invention is divided into three stages, and the first stage is mainly used to digest the V in the titanium-based denitrification catalyst. 2 o 5 , Fe 2 o 3 , CuO, CrOx, MnOx, MgO, MoO 3 , NiO and other components, and can also partially digest WO 3 、TiO 2 and other components; the second stage mainly promotes the WO that cannot be completely digested in the first stage 3 、TiO 2 Another key role is to promote the tungsten and titanium ions entering the solution to form complex ions with phosphate and sulfate, so as to avoid the precipitation of tungsten in acidic medium with tungstic acid, etc. Form precipitation, as well as the hydrolysis reaction of high-concentration titanium, can also further ensure that other residual components that have not been completely digested in the first stage are completely reacted into the solution; the third stage is mainly produced by heating and reacting until phosph...

Embodiment 1

[0042] Digestion of titanium-based denitration catalyst samples

[0043] Weigh 0.1000g of titanium-based denitrification catalyst sample (hereinafter referred to as sample No. 1) into a polytetrafluoroethylene beaker, add 2mL of hydrofluoric acid and 3mL of nitric acid, then rinse the bottle wall with about 5mL of water, heat and digest the sample to the solution Boiling; then add 6mL mixed solution of sulfuric acid, phosphoric acid and water prepared in the ratio of (2+1+5), continue to heat and digest the sample until the reaction is complete and the solution is clear; heat and evaporate the solution until thick white phosphorus pentoxide or For the flue gas of sulfur trioxide, keep the smoking state for 2 minutes, transfer the test solution to a 100mL volumetric flask after cooling, dilute to the mark with distilled water, and mix well.

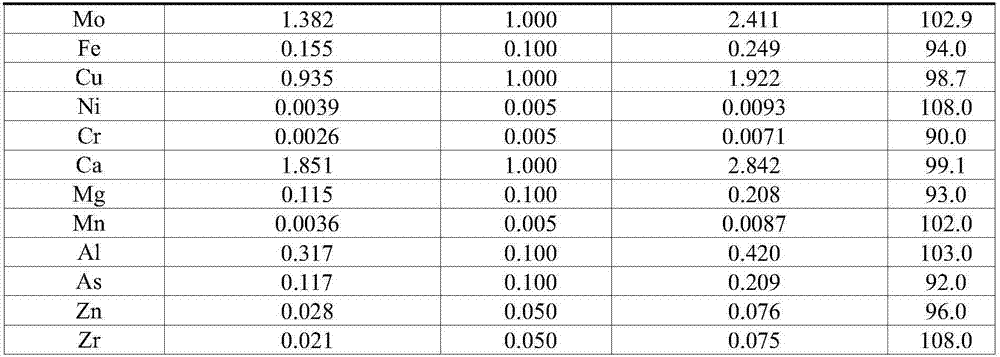

[0044] Determination of Chemical Element Contents in Titanium-based Denitrification Catalyst Sample Solution by ICP-OES

[0045] Using i...

Embodiment 2

[0049]The sample to be digested is 0.2000g titanium-based denitration catalyst sample (hereinafter referred to as No. 2 sample), add 4mL hydrofluoric acid and 6mL nitric acid, wash the bottle wall with about 10mL water, heat the digested sample until the solution boils; add 12mL to ( 2+1+5) mixed solution of sulfuric acid, phosphoric acid and water prepared in proportion, continue to heat and digest the sample until the reaction is complete and the solution is clear; heat and evaporate the solution to produce thick white phosphorus pentoxide or sulfur trioxide flue gas, keep The smoking state is 4min, after cooling, transfer the test solution to a 100mL volumetric flask, dilute to the mark with distilled water, and mix well.

[0050] In addition, the titanium-based denitration catalyst sample was digested according to the same method as Example 1, and the content of chemical elements in the sample solution was detected by ICP-OES.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com