High-functionality hydroxyl-terminated polyurethane aqueous dispersion as well as preparation method and application thereof

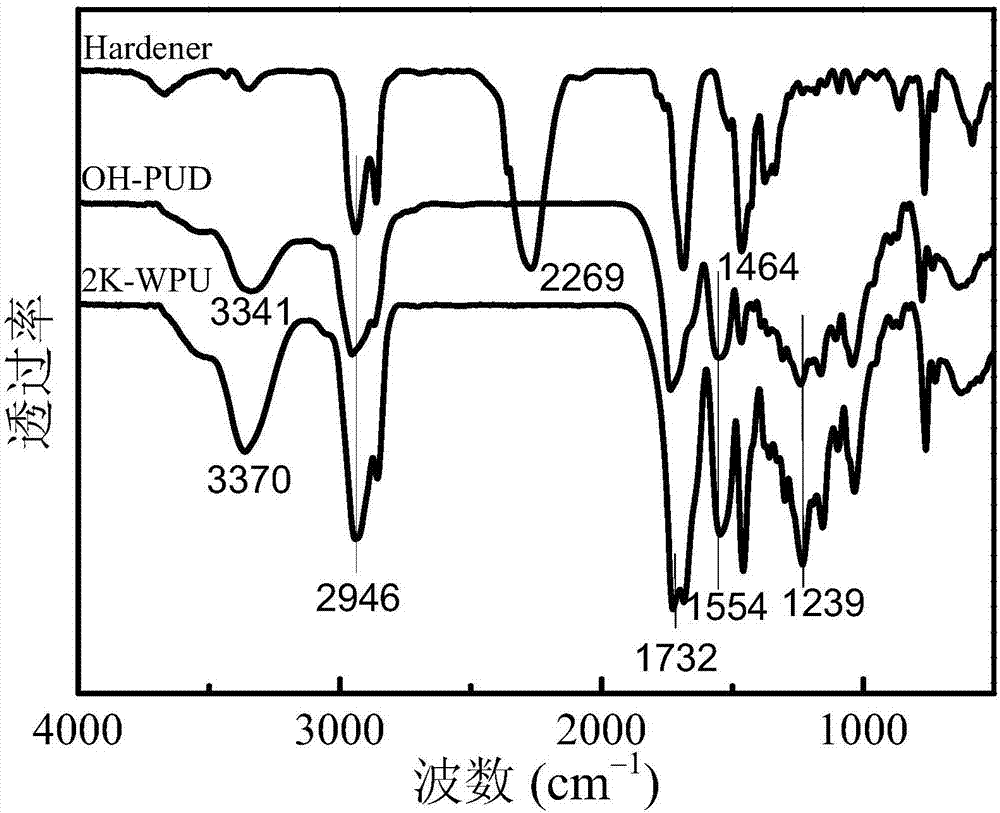

A technology of hydroxyl-terminated polyurethane with high functionality, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problem of inability to guarantee the hydroxyl functionality of OH-PUD, unfavorable improvement of crosslinking degree of two-component coatings, OH-PUD Solve problems such as low solid content, achieve the effect of increasing the average hydroxyl functionality, high average hydroxyl functionality, and excellent yellowing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

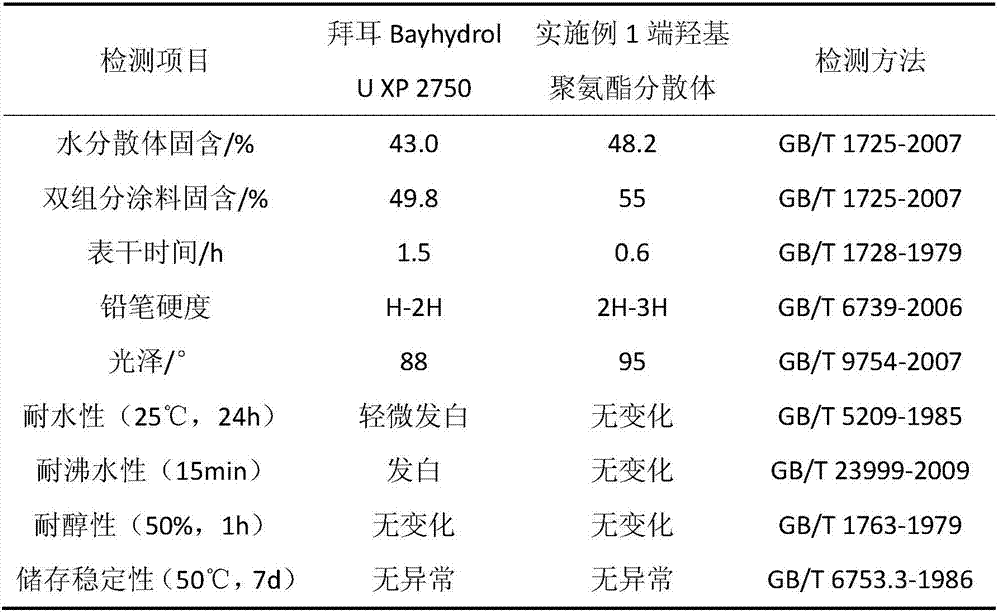

Examples

Embodiment 1

[0041] (1) Preparation of hydroxyl-terminated polyurethane aqueous dispersion

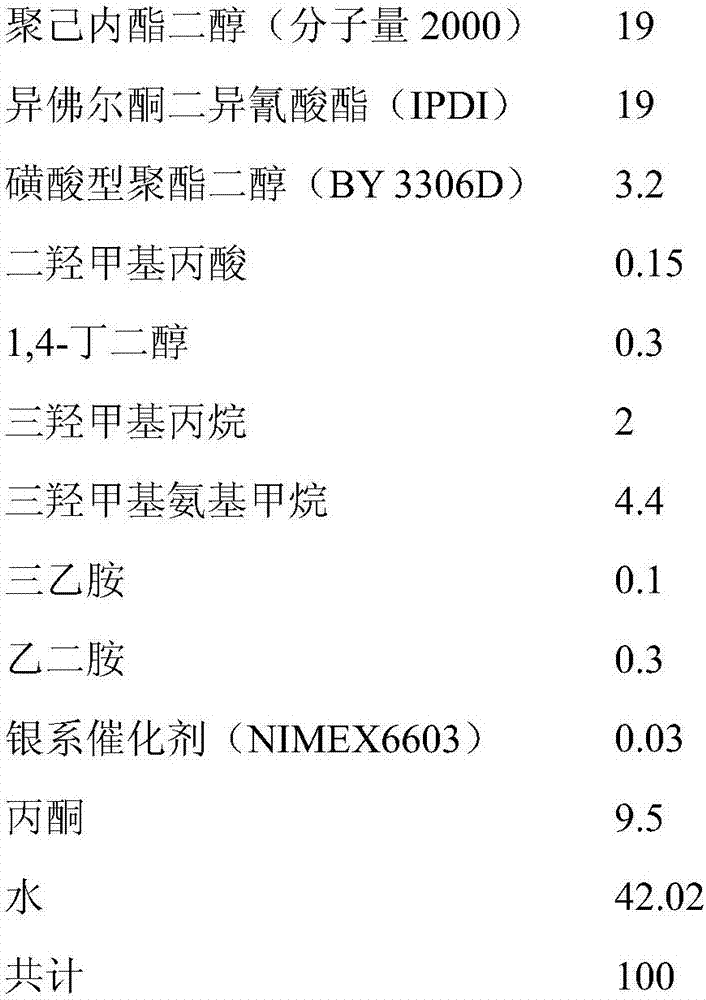

[0042] The type and mass percentage of each component raw material:

[0043]

[0044] Preparation process: polycaprolactone diol (molecular weight 2000), isophorone diisocyanate (IPDI), sulfonic acid polyester diol, dimethylol propionic acid, silver catalyst and acetone (accounting for acetone in the formula The mass percentage of 20%) was added to the reactor, and the temperature was raised to 75°C for 3.5 hours under nitrogen protection. When the NCO% of the system reached the theoretical value, the temperature was lowered to 65°C, and 1,4-butanediol and The solution of trimethylolpropane in acetone (accounting for 30% of the mass percentage of acetone in the formula) was reacted at 70°C for 1.5h. ), cooling to 40°C, adding triethylamine to neutralize, adding water to disperse under high-speed shearing (accounting for the consumption of 90% water in the mass percentage of water in the formula...

Embodiment 2

[0054] (1) Preparation of hydroxyl-terminated polyurethane aqueous dispersion

[0055] The type and mass percentage of each component raw material:

[0056]

[0057] Preparation process: polytetrahydrofuran ether diol (molecular weight 2000), hexamethylene diisocyanate (HDI), sulfonic acid polyester diol, dimethylol butyric acid, silver catalyst and acetone (accounting for 20% by mass of acetone in the formula) %) into the reactor, under the protection of nitrogen, the temperature was raised to 80°C for 3 hours, and when the NCO% of the system reached the theoretical value, the temperature was lowered to 65°C, and 1,4-butanediol and trimethylolpropane were added dropwise within 40 minutes A solution of acetone (accounting for 30% of the mass percent of acetone in the formula) was reacted at 75°C for 1.5h. When the NCO% of the system reached the theoretical value, an appropriate amount of acetone was added for dilution (accounting for 50% of the mass percent of acetone in th...

Embodiment 3

[0065] (1) Preparation of hydroxyl-terminated polyurethane aqueous dispersion

[0066] The type and mass percentage of each component raw material:

[0067]

[0068] Preparation process: polycaprolactone diol (molecular weight 2000, molecular weight 1000), dicyclohexylmethane diisocyanate (HMDI), sulfonic acid type polyester diol, silver catalyst and a small amount of acetone (accounting for the mass percentage of acetone in the formula 20%) into the reaction kettle, under the protection of nitrogen, the temperature was raised to 80°C for 4 hours, and when the NCO% of the system reached the theoretical value, the temperature was lowered to 70°C, and 1,4-butanediol and trimethylol were added dropwise within 25 minutes Propane in acetone (accounting for 30% of the mass percent of acetone in the formula) solution, reacted at 75°C for 1.0h, and when the NCO% of the system reached the theoretical value, add an appropriate amount of acetone for dilution (accounting for 50% of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com