Preparation method of glucosamine sulfate compound salt

A technology of glucosamine sulfate and glucosamine, which is applied in the field of preparation of glucosamine sulfate double salt, can solve the problems of organic solvent toxicity residue, reaction kettle corrosion, preparation instability, etc., and achieve simple production process, high product purity and high cost efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

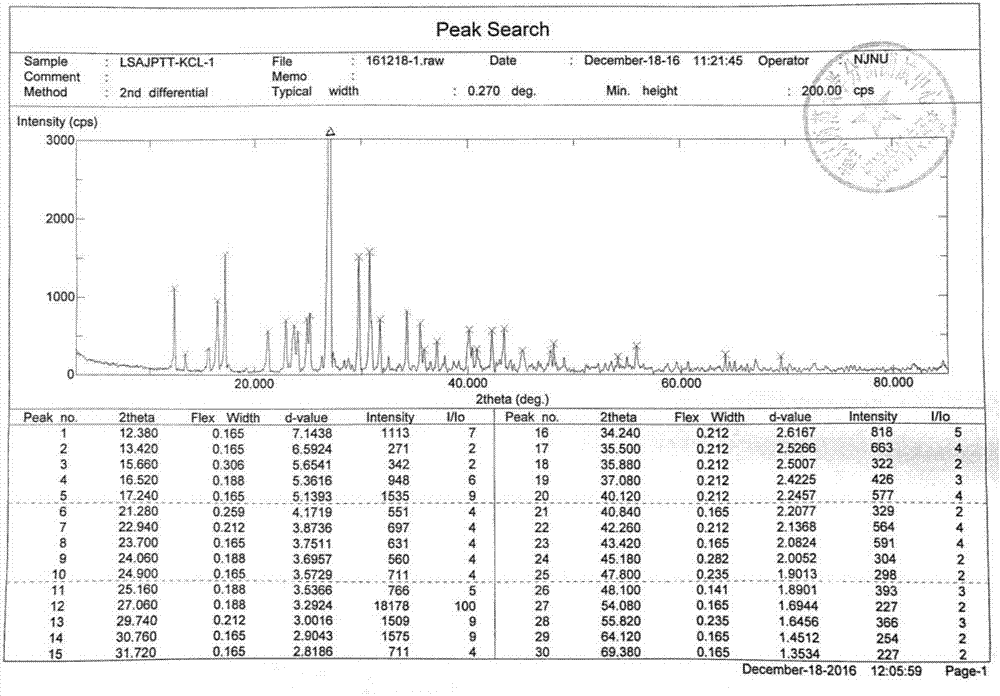

Image

Examples

Embodiment 1

[0025] A preparation method of glucosamine sulfate double salt, comprising the following steps:

[0026] (1) Preparation of glucosamine: adding an appropriate amount of chitin and a concentration of 40% Na in the three-necked flask 2 CO 3 solution, Na 2 CO 3 The ratio of the amount of chitin to the substance is 0.2:1, heated to 40°C by 400W microwave for deacetylation reaction, the reactant is taken out every 3min, filtered and washed with water, and then added with Na 2 CO 3 Solution treatment, washed with water until neutral, and dried at 50°C.

[0027] (2) Preparation of glucosamine sulfate: the glucosamine solution obtained by step (1) is made into a 20% glucosamine solution, and an excess concentration of 25% (NH 4 ) 2 SO 4 The solution was neutralized and sulfated, the reaction temperature was 30°C, the ammonia generated during the process was removed by chlorine gas, filtered after reacting for 5 hours, activated carbon was added to the filtrate for decolorizatio...

Embodiment 2

[0032] A preparation method of glucosamine sulfate double salt, comprising the following steps:

[0033] (1) Preparation of glucosamine: adding an appropriate amount of chitin and a concentration of 50% Na in the three-necked flask 2 CO 3 solution, Na 2 CO 3 The ratio of the amount of chitin to the substance is 0.35:1, heated to 45°C by 900W microwave for deacetylation reaction, the reactant is taken out every 7min, filtered and washed with water, and then added with Na 2 CO 3 Solution treatment, washed with water until neutral, and dried at 55°C.

[0034] (2) Preparation of glucosamine sulfate: the glucosamine obtained in step (1) is made into a glucosamine solution with a concentration of 45%, and an excessive concentration of 25% NH is added to the glucosamine solution. 4 HSO 4 The solution was neutralized and sulfated, the reaction temperature was 40°C, the ammonia generated during the process was removed by chlorine gas, filtered after 12 hours of reaction, activate...

Embodiment 3

[0039] A preparation method of glucosamine sulfate double salt, comprising the following steps:

[0040] (1) Preparation of glucosamine: adding an appropriate amount of chitin and a concentration of 45% Na in the three-necked flask 2 CO 3 solution, Na 2 CO3 The ratio of the amount of chitin to the substance is 0.2:1, heated to 50°C by 600W microwave for deacetylation reaction, the reactant is taken out every 3min, filtered and washed with water, and then added with Na 2 CO 3 Solution treatment, washed with water until neutral, and dried at 60°C.

[0041] (2) Preparation of glucosamine sulfate: the glucosamine obtained in step (1) is made into a glucosamine solution with a concentration of 30%, and an excessive concentration of 30% (NH 4 ) 2 SO 4 The solution was neutralized and sulfated at a reaction temperature of 45°C. The ammonia generated during the process was removed by chlorine gas. After reacting for 5 hours, it was filtered, and activated carbon was added to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific rotation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com