High-magnetic-shielding inductor with molybdenum permalloy core and manufacture method thereof

A manufacturing method and inductor technology, applied in magnetic core manufacturing, inductor/transformer/magnet manufacturing, transformer/inductor casing, etc., can solve problems such as poor stability and shielding ability, poor temperature stability, and no specific instructions , to achieve the effects of good stability, excellent heat dissipation performance and excellent electromagnetic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

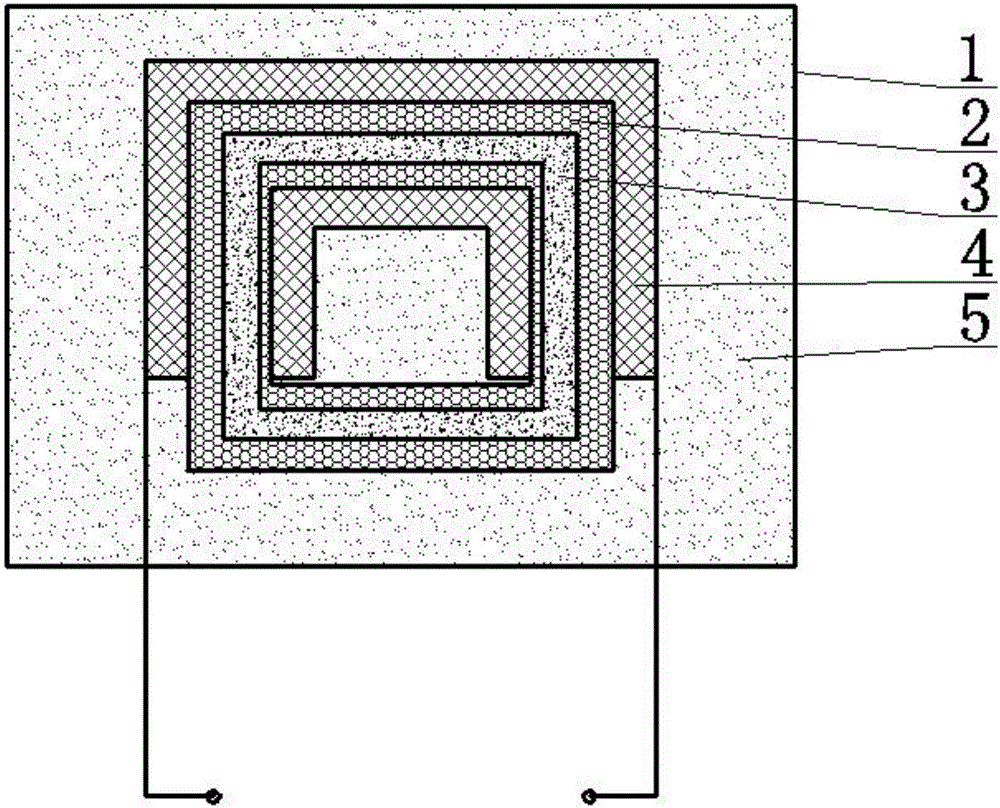

Embodiment 1

[0036] A high magnetic shielding inductor using a molybdenum permal magnetic core, including a skeleton, a winding 4, a magnetic core 3, a shielding cover 1, and a packaging material; the aluminum nitride ceramic skeleton 2 is used; the winding 4 is made of 1140 epoxy Carbon fiber wire made of polyester insulating varnish; the shielding case 1 is made of aluminum alloy and packaged in a fully enclosed structure; the gap between the shielding case 1 and other parts except the shielding case 1 is filled with granular heat-conducting insulating material 5, the heat-conducting insulation Material 5 is a granular mixture of silicone rubber and glass fiber in a weight ratio of 9:1.

[0037] The above-mentioned manufacturing method of the high magnetic shield inductor using the molypermal magnetic core comprises the following steps:

[0038] 1) Selection and preparation of various components

[0039] ① The skeleton is selected from the aluminum nitride-based ceramic skeleton 2 that ...

Embodiment 2

[0063] A method for manufacturing a high magnetic shield inductor using a molypermal magnetic core, comprising the following steps:

[0064] 1) Selection and preparation of various components

[0065] ① The skeleton is selected from the aluminum nitride-based ceramic skeleton 2 that matches the square-shaped magnetic core 3, and the selection standard of the aluminum nitride-based ceramic is: volume resistivity ≥ 2×10 13 Ω cm, dielectric strength ≥ 750kV / cm, thermal conductivity ≥ 25W / m K, flexural strength ≥ 400Mpa, Young's modulus ≥ 320Gpa, fracture toughness ≥ 25Mpa;

[0066] ②Magnetic core 3 is made of molybdenum permalloy strip. The selection standard of this molybdenum permalloy strip is: its raw material contains 3.2%-3.8% molybdenum, 15.8%-17.2% iron, 79%-81% nickel, and its inductance The stability value is not higher than 0.03%, and the initial inductance offset range value is not higher than 0.3%;

[0067] ③The shielding cover 1 is made of aluminum alloy and adopt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume resistivity | aaaaa | aaaaa |

| Dielectric strength | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com