A kind of preparation method of reflective thermal insulation ceramic glazed tile

A ceramic glaze and tile technology, applied in the field of building ceramics, can solve the problems of unfavorable industrialization, large power consumption, long time consumption, etc., and achieve the effects of large power consumption, large consumption and long time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

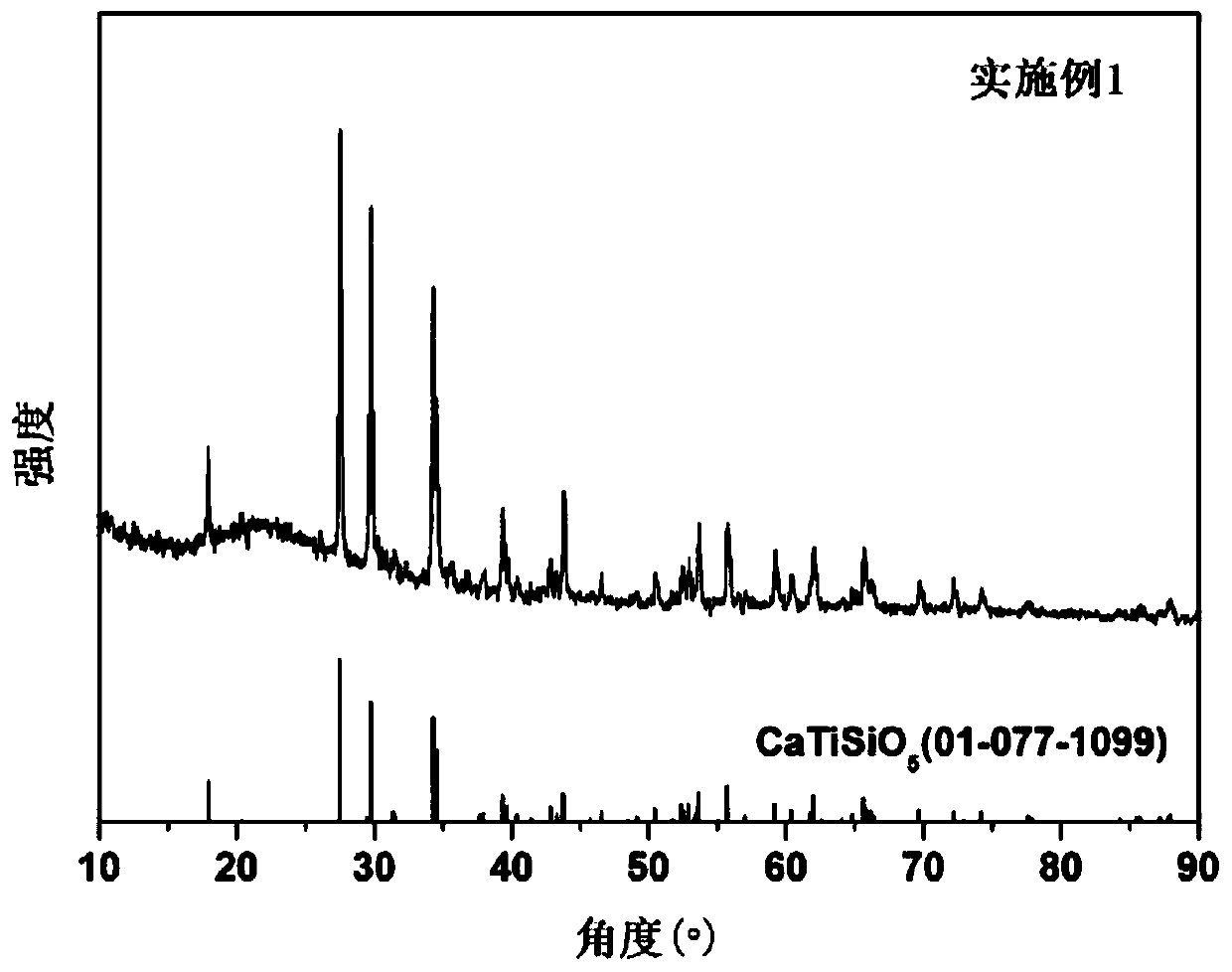

Embodiment 1

[0044] A method for preparing reflective and heat-insulating ceramic glazed tiles, comprising the steps of:

[0045] 1) Fully mix 26 parts of quartz, 20 parts of feldspar, 6 parts of calcite, 42 parts of titanium dioxide, 4 parts of dolomite, 1.5 parts of alumina and 0.5 parts of zinc oxide, melt in a frit furnace until all the raw materials are melted, and melt The melting temperature is 1600°C, and the frit is fused into a frit; in terms of mass percentage, the chemical composition of the frit obtained after smelting is: 40wt% SiO 2 , 6wt% Al 2 o 3 , 2wt%Na 2 O, 0.5wt%K 2 O, 5wt% CaO, 1wt% MgO, 0.5wt% ZnO, 45wt% TiO 2 .

[0046] 2) In terms of parts by mass, mix 10 parts of frit obtained in step 1) with 8 parts of clay, 5 parts of kaolin, 35 parts of quartz, 15 parts of feldspar, 15 parts of calcite, 7 parts of titanium dioxide and 5 parts of talc Grind to make a glaze slurry.

[0047] 3) The glaze slurry prepared in step 2) is applied on the green brick by a glaze sp...

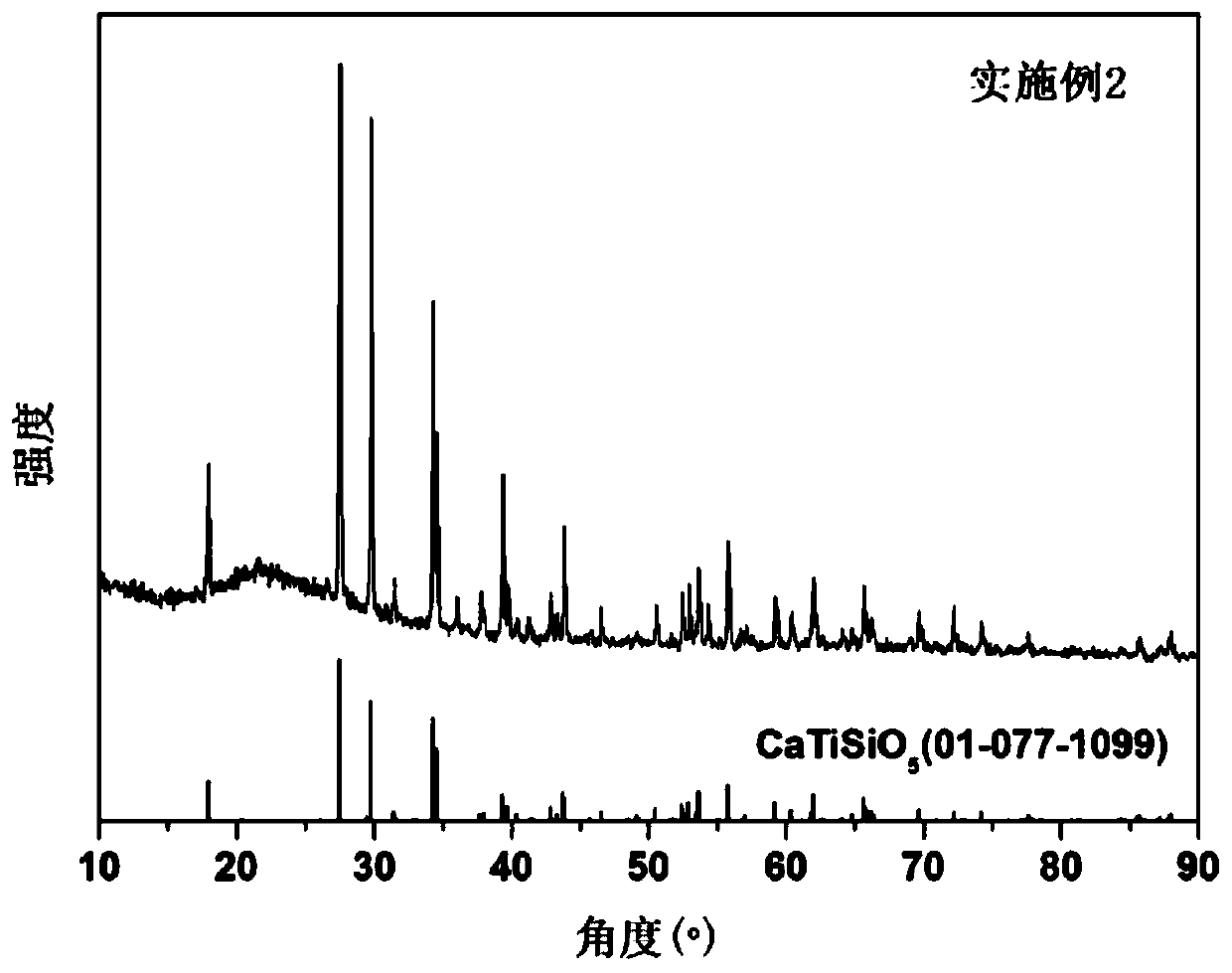

Embodiment 2

[0052] A method for preparing reflective and heat-insulating ceramic glazed tiles, comprising the steps of:

[0053] 1) In parts by mass, 30 parts of quartz, 25 parts of feldspar, 10.5 parts of calcite, 27 parts of titanium dioxide, 3 parts of talc, 1.5 parts of aluminum oxide, 1 part of zinc oxide, 1 part of barium carbonate and 1 part of apatite Stones are fully mixed and melted into a frit in a frit furnace at a melting temperature of 1550°C; in terms of mass percentage, the chemical composition of the frit is: 50wt% SiO 2 , 7wt% Al 2 o 3 , 3wt%Na 2 O, 7wt% CaO, 1wt% MgO, 1wt% ZnO, 0.5wt% BaO, 0.5wt% P 2 o 5 , 30wt%TiO 2 .

[0054] 2) Mix and grind 30 parts of the frit obtained in step 1) with 7 parts of clay, 25 parts of quartz, 15 parts of feldspar, 15 parts of wollastonite, 5 parts of titanium dioxide and 3 parts of dolomite to prepare a glaze slurry.

[0055] 3) The glaze slurry prepared in step 2) is applied on the green brick by a glaze sprayer.

[0056] 4) Af...

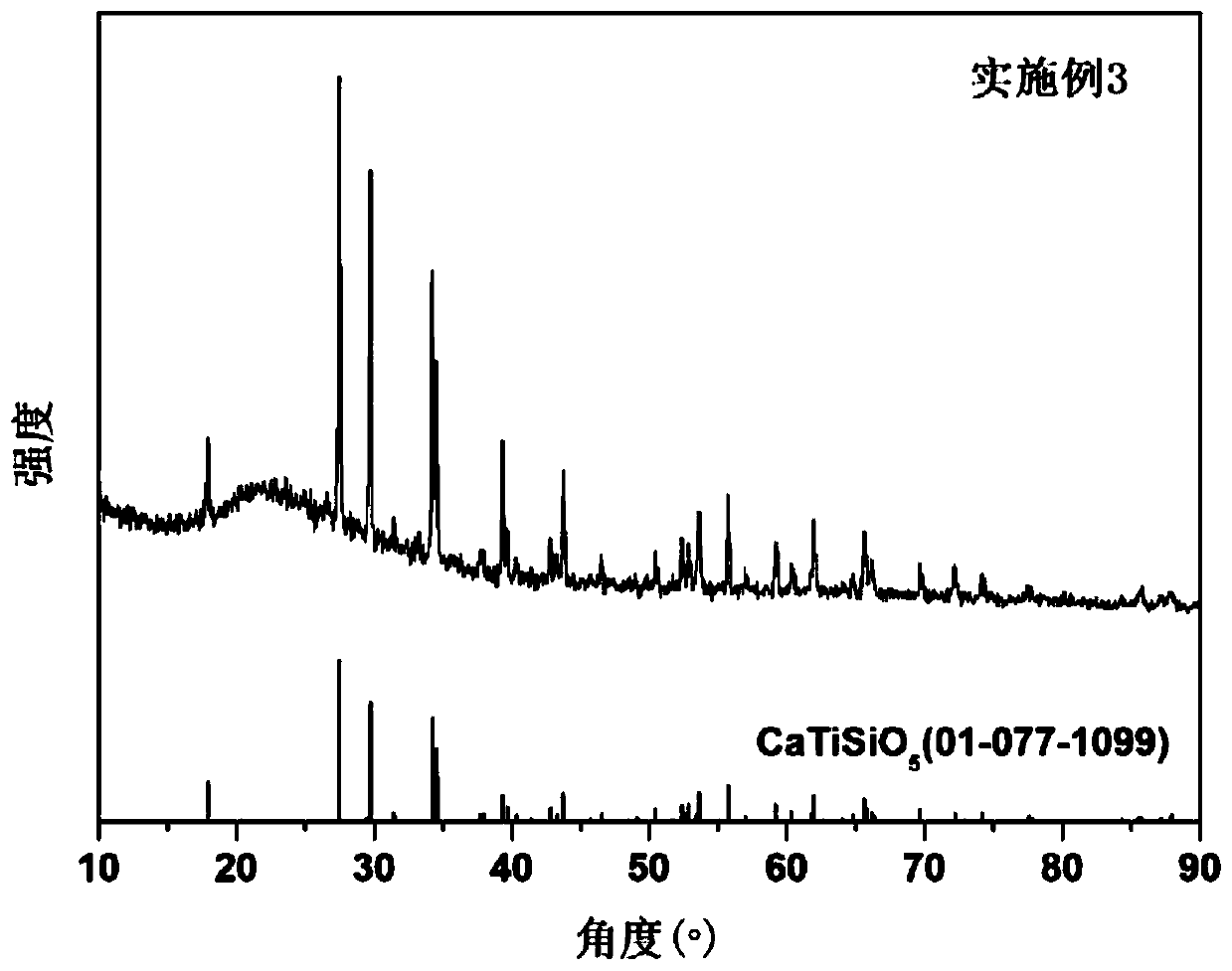

Embodiment 3

[0060] A method for preparing reflective and heat-insulating ceramic glazed tiles, comprising the steps of:

[0061] 1) Fully mix 23 parts of quartz, 25 parts of feldspar, 12 parts of heavy calcium carbonate, 18 parts of titanium dioxide, 9 parts of alumina, 11 parts of talc and 2 parts of strontium carbonate, and melt into a frit in a frit furnace , the melting temperature is 1550°C; in terms of mass percentage, the chemical composition of the frit is: 49wt% SiO 2 , 15wt%Al 2 o 3 , 3wt%K 2 O, 8wt% CaO, 4wt% MgO, 1wt% SrO, 20wt% TiO 2 .

[0062] 2) Combine 50 parts of frit obtained in step 1) with 8 parts of clay, 13 parts of quartz, 10 parts of feldspar, 10 parts of calcite, 5 parts of talc, 2 parts of strontium carbonate, 1 part of titanium dioxide, and 1 part of spodumene Mix and grind to make a glaze slurry.

[0063] 3) The glaze slurry prepared in step 2) is applied on the green brick by a glaze sprayer.

[0064] 4) After drying the glazed body in step 3), it is fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com