Method for preparing K2B12H12

A kind of K2B12H12, aprotic technology, applied in the field of preparation chemistry of ionic polyboron hydrides, can solve the problems of complex process procedure, rising preparation cost, increasing reaction species, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

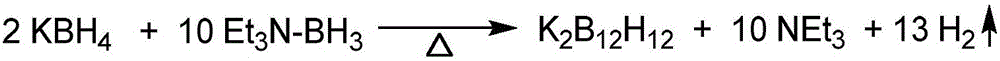

Method used

Image

Examples

Embodiment 1

[0035] In an inert atmosphere, the KBH 4 49.5g and about 500mL Et 3 N·BH 3 After mixing in a two-liter three-neck reaction flask, add about 440mL Et to the constant pressure dropping funnel installed on the reaction flask 3 N·BH 3 . Heating under stirring, the temperature was raised to 200°C by itself, maintained for one hour, and then raised to 215°C. After 1.5 h, about 60 mL of triethylamine was received. Add triethylamine borane dropwise to keep the liquid level in the bottle as high as possible. After 18 hours of reaction, 515 mL of distillate (60-90° C.) was received. Then the reaction intensified, and the distillation temperature increased. After 4 hours, another 100mL of liquid was received; the reaction subsided, and the amount of outgassing decreased significantly. Stop stirring, cool to about 130°C, remove the reflux and fractionation device on the three-necked flask; continue with vacuum distillation; raise the temperature to 160-180°C, and distill off the ...

Embodiment 2

[0037] Add 28g KBH in the device similar to embodiment 1 4 (500mmol) and 288g Et 3 N·BH 3 (2500mmol); heated in an Ar atmosphere, the temperature rose to 180°C (about 2 hours) by itself, hydrogen gas was released, and a small amount of liquid distilled out (Et 3 N); then heated at intervals of 5°C to 210-230°C and heated for 3 hours, the hydrogen release rate slowed down significantly, cooled to about 100°C in an Ar atmosphere, installed a decompression device, decompressed to remove volatiles, and left a light yellow The solid was treated with toluene, petroleum ether, diethyl ether and isopropanol to obtain a white powdery solid. Add deionized water to the solid to dissolve, concentrate the aqueous solution, cool, and precipitate colorless and transparent K 2 B 12 h 12 Crystal, the yield is about 50%.

Embodiment 3

[0039] In a device similar to Example 1, 2.8g KBH 4 (50mmol) and 12g Et 3 N·BH 3 (100mmol) in high purity N 2 In the atmosphere, react in diethylene glycol dimethyl ether at 130°C for 10 hours, then raise the temperature to reflux temperature for 16 hours, cool, filter, and treat the solid with dichloromethane, ether, acetonitrile, methanol and water to obtain a colorless and transparent K 2 B 12 h 12 crystals.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com