Method for preparing cheap light rare earth lanthanum cerium iron boron nano-crystal permanent magnet

A light rare earth, nanocrystalline technology, used in magnetic objects, inductance/transformer/magnet manufacturing, magnetic materials, etc., can solve the problem of difficult magnetic hardening of magnets, no pure lanthanum cerium bulk magnets, low intrinsic magnetic properties, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

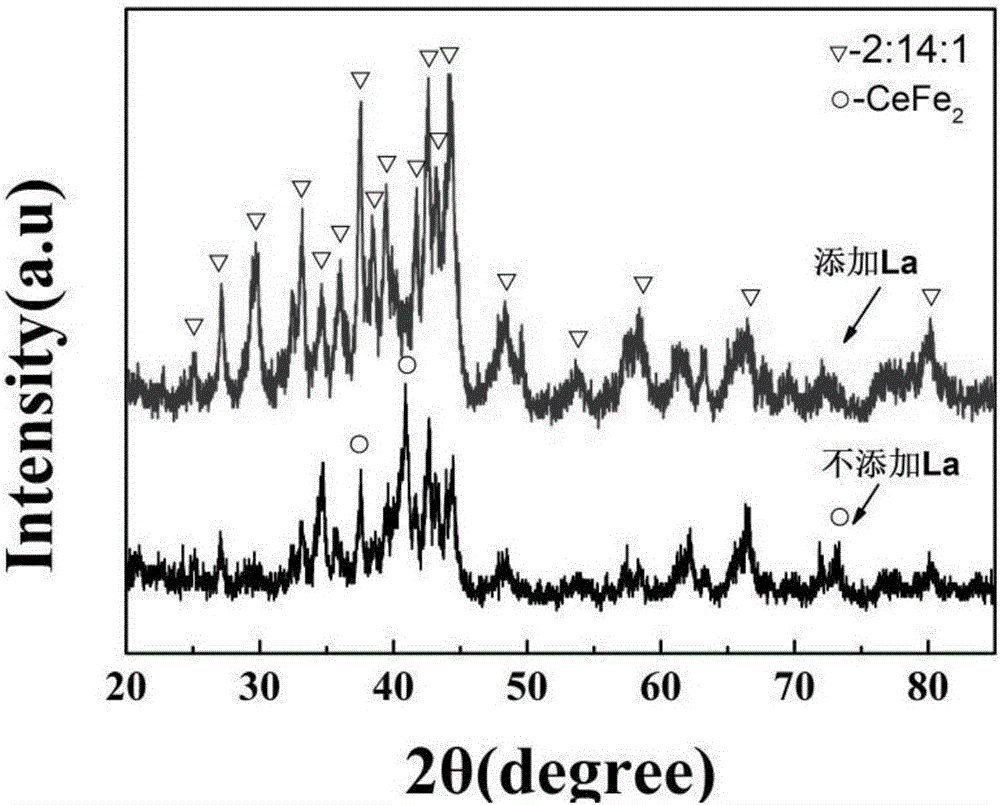

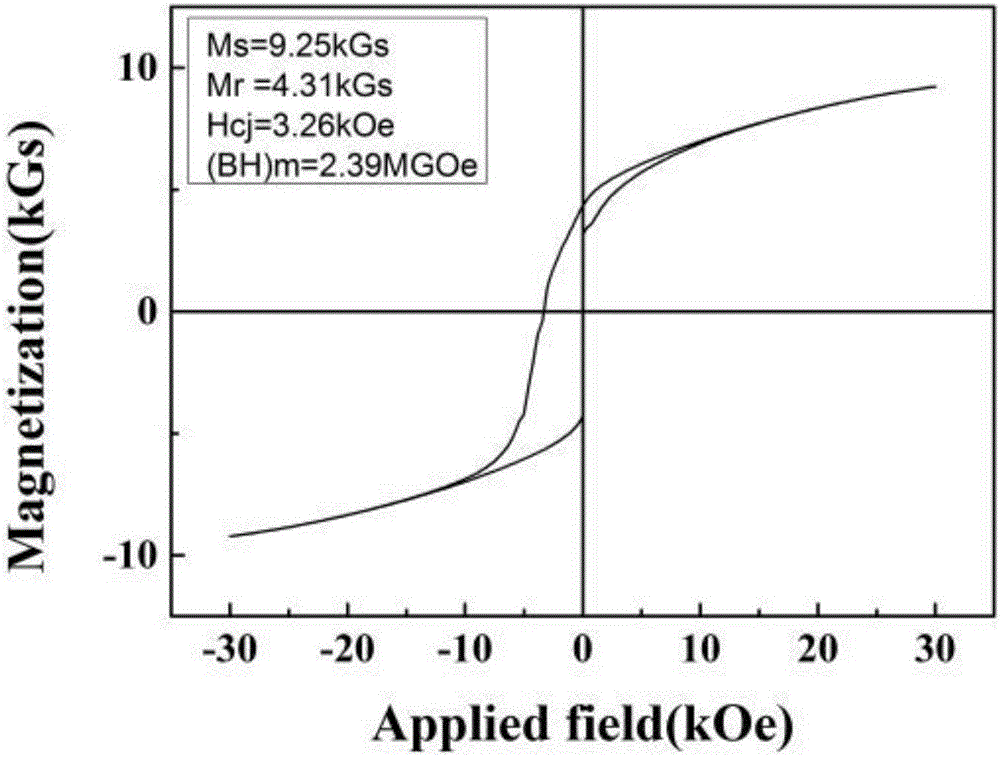

[0025] A (La 0.3 Ce 0.7 ) 2 Fe 14 B hot-pressed magnet preparation, implement according to the following steps:

[0026] In the first step, press (La 0.3 Ce0.7 ) 2 Fe 14 Proportion B is carried out, and after the batching is completed, it is placed in a suspension melting furnace, heated to melt it under an argon atmosphere, mixed evenly and cooled to room temperature naturally, and smelted repeatedly in this way for 4 times to obtain a uniform ingot;

[0027] In the second step, the ingot obtained in the first step is taken out, the surface oxide is mechanically polished off, and mechanically crushed, the ingot fragments are as uniform as possible, and then put into a quartz tube;

[0028] The third step is to install the quartz tube containing the ingot on the melt quenching equipment, turn on the heating system to melt the ingot block, let the alloy liquid spray from the nozzle to the high-speed rotating copper roller, and then collect the quenching belt. The surface...

Embodiment 2

[0032] A (La 0.3 Ce 0.7 ) 3 Fe 14 B hot-pressed magnet preparation, implement according to the following steps:

[0033] In the first step, press (La 0.3 Ce 0.7 ) 3 Fe 14 Proportion B is carried out, and after the batching is completed, it is placed in a suspension melting furnace, heated to melt it under an argon atmosphere, mixed evenly and cooled to room temperature naturally, and smelted repeatedly in this way for 4 times to obtain a uniform ingot;

[0034] In the second step, the ingot obtained in the first step is taken out, the surface oxide is mechanically polished off, and mechanically crushed, the ingot fragments are as uniform as possible, and then put into a quartz tube;

[0035] The third step is to install the quartz tube containing the ingot on the melt quenching equipment, turn on the heating system to melt the ingot block, let the alloy liquid spray from the nozzle to the high-speed rotating copper roller, and then collect the quenching belt. The surfa...

Embodiment 3

[0039] A (La 0.3 Ce 0.7 ) 4 Fe 14 B hot-pressed magnet preparation, implement according to the following steps:

[0040] In the first step, press (La 0.3 Ce 0.7 ) 4 Fe 14 Proportion B is carried out, and after the batching is completed, it is placed in a suspension melting furnace, heated to melt it under an argon atmosphere, mixed evenly and cooled to room temperature naturally, and smelted repeatedly in this way for 4 times to obtain a uniform ingot;

[0041] In the second step, the ingot obtained in the first step is taken out, the surface oxide is mechanically polished off, and mechanically crushed, the ingot fragments are as uniform as possible, and then put into a quartz tube;

[0042] The third step is to install the quartz tube containing the ingot on the melt quenching equipment, turn on the heating system to melt the ingot block, let the alloy liquid spray from the nozzle to the high-speed rotating copper roller, and then collect the quenching belt. The surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com