Method for preparing flame-retardant melt-proof fibers

An anti-melt drop and fiber technology, which is applied in the manufacture of fire-retardant and flame-retardant filaments, single-component polyolefin rayon, single-component polyamide rayon, etc. The effect of simple production and process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

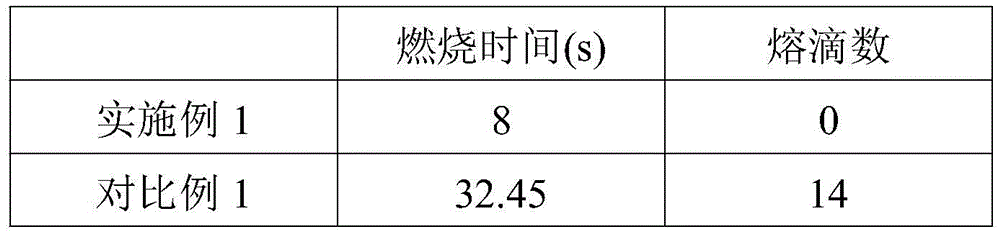

Embodiment 1

[0021] The specific process of preparing flame-retardant anti-melt droplet fiber in this embodiment is as follows:

[0022] (1) Dry the PET chips at a temperature of 120°C until the moisture content reaches 300ppm, add graphene and melamine powder to it, and mix and extrude it in a twin-screw extruder at a temperature of about 280°C to obtain a flame-retardant Anti-melt drop polyester masterbatch, the flame-retardant anti-melt drop polyester masterbatch contains 10% graphene powder with a particle size of 0.5 μm, 20% melamine and 70% PET by weight;

[0023] (2) Pre-crystallize the PET chips at a temperature of 120°C, and dry them at a temperature of 140°C until the moisture content reaches 300ppm; the flame-retardant and anti-droplet polyester masterbatch prepared in step (1) is dried at a temperature of 140°C Dry at high temperature until the moisture content reaches 300ppm; add the dried flame-retardant and anti-droplet polyester masterbatch to the PET chip with a volumetric...

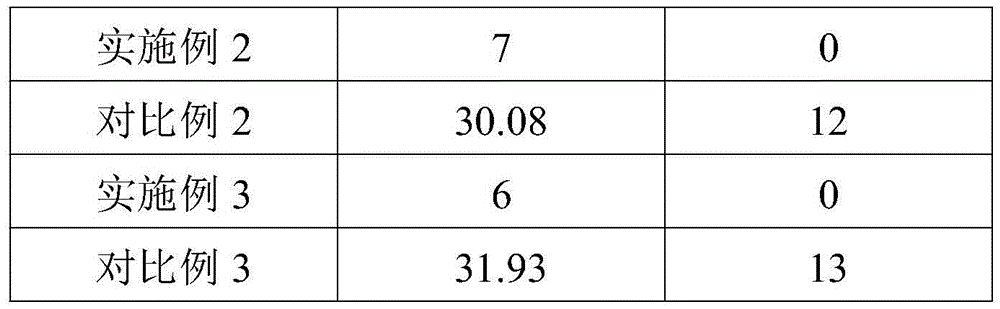

Embodiment 2

[0025] The specific process of preparing flame-retardant anti-melt droplet fiber in this embodiment is as follows:

[0026] (1) Dry the PA6 chips at a temperature of about 105°C until the moisture content is lower than 0.08%, add graphene oxide and melamine cyanurate powder to it, and mix them in a twin-screw extruder at a temperature of about 230°C Extruding, thereby making flame-retardant anti-melt drop polyamide master batch, described flame-retardant anti-melt drop polyamide master batch comprises 5% graphene oxide powder with a particle diameter of 0.5 μm by weight, 10% melamine Cyanurate and 85% PA6;

[0027] (2) Dry the PA6 chips at 105°C to make the moisture content lower than 0.08%; The flame-retardant and anti-melt drop masterbatch is quantitatively added to PA6 chips, so that the content of graphene oxide in PA6 is 1%, and conventional nylon spinning equipment and technology are used to spin 150d / 24f PA6 fully drawn yarn.

Embodiment 3

[0029] The specific process of preparing flame-retardant anti-melt droplet fiber in this embodiment is as follows:

[0030] (1) After premixing PP slices, nano-graphite and melamine, they are mixed and extruded in a twin-screw extruder at a temperature of about 180°C to obtain a flame-retardant and anti-melt drop polypropylene masterbatch. Melted polypropylene masterbatch contains 10% graphite powder with a particle size of 1 μm, 10% melamine and 80% PP by weight;

[0031] (2) The above-mentioned flame-retardant and anti-melt drop masterbatch is spun into 75d / 42f PP fully drawn yarn by using conventional polypropylene spinning equipment and technology.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com