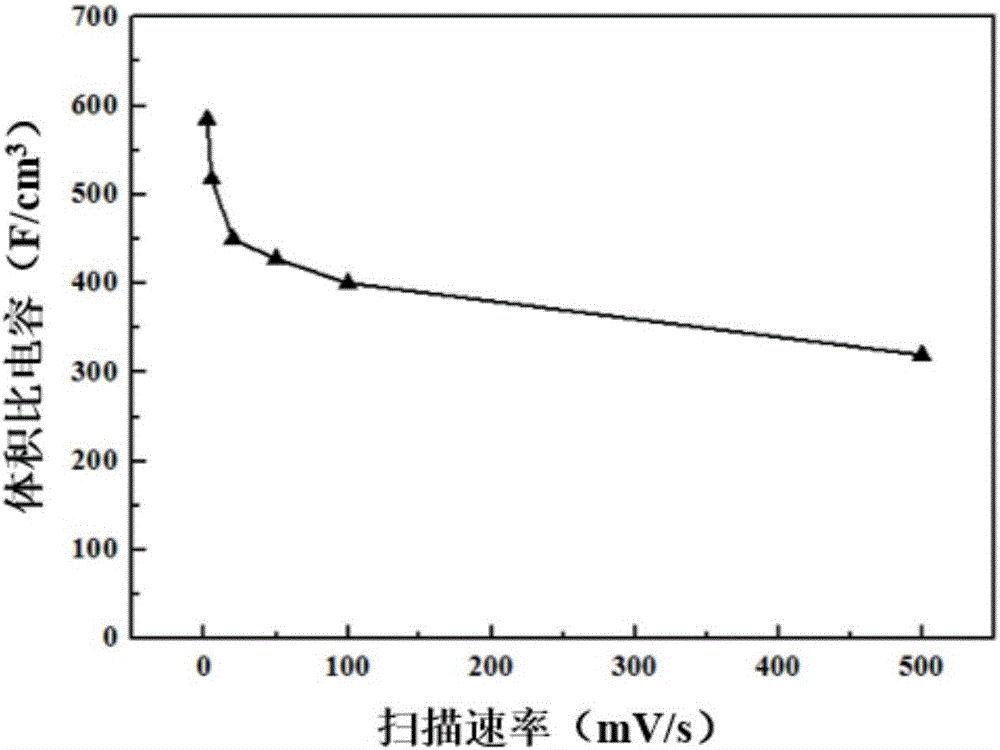

High volumetric specific capacitance flexibility molybdenum sulfide gel film electrode materials and preparation method thereof

A technology of molybdenum sulfide gel and thin-film electrodes, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double-layer capacitors, and can solve problems such as poor capacitance performance and difficult problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Take the molybdenum sulfide powder in the 2H configuration, put it into an argon-protected round bottom flask, slowly add n-butyllithium hexane solution at a molar ratio of 1:2, and magnetically stir and reflux at 80°C for 48 hours to achieve For the lithium intercalation reaction of molybdenum sulfide, the resulting reaction product was washed with n-hexane several times, and dried in vacuum at a temperature of 40°C for 2 hours;

[0027] (2) Take the product of step (1), add deionized water and stir to prepare a 2 mg / mL molybdenum sulfide dispersion, and use an ultrasonic cell pulverizer at a power of 80W to peel and crush for 15 minutes;

[0028] (3) Centrifuging the molybdenum sulfide dispersion liquid through peeling and crushing at a speed of 6000 rpm for 30 minutes multiple times to obtain a uniform metallic molybdenum sulfide dispersion liquid;

[0029] (4) select the mixed cellulose filter membrane that aperture is 50nm for use, adopt the method suction filt...

Embodiment 2

[0034] (1) Take molybdenum sulfide powder in 2H configuration, put it into an argon-protected round bottom flask, slowly add n-butyllithium hexane solution at a molar ratio of 1:1, and magnetically stir and reflux at 70°C for 40 hours to achieve For the lithium intercalation reaction of molybdenum sulfide, the resulting reaction product was washed several times with n-hexane, and dried in vacuum at a temperature of 25°C for 3 hours;

[0035] (2) Take the product of step (1), add deionized water and stir to prepare a 1 mg / mL molybdenum sulfide dispersion, and use an ultrasonic cell pulverizer at a power of 60W to peel and crush for 5 minutes;

[0036] (3) Centrifuging the molybdenum sulfide dispersion liquid at a rate of 5000 rpm for several times for 20 minutes through stripping and crushing to obtain a uniform metallic molybdenum sulfide dispersion liquid;

[0037] (4) select the mixed cellulose filter membrane that aperture is 25nm for use, adopt the method suction filtratio...

Embodiment 3

[0041] (1) Take molybdenum sulfide powder in 2H configuration, put it into an argon-protected round bottom flask, slowly add n-butyllithium hexane solution at a ratio of 1:3 in molar ratio, and magnetically stir and reflux at 80°C for 50 hours to achieve For the lithium intercalation reaction of molybdenum sulfide, the resulting reaction product was washed several times with n-hexane, and dried in vacuum at a temperature of 50°C for 1 hour;

[0042] (2) Take the product of step (1), add deionized water and stir to prepare a 3mg / mL molybdenum sulfide dispersion, and use an ultrasonic cell pulverizer at a power of 120W to peel and crush for 20 minutes;

[0043] (3) Centrifuging the molybdenum sulfide dispersion liquid through peeling and crushing at a speed of 8000 rpm for 40 minutes multiple times to obtain a uniform metallic molybdenum sulfide dispersion liquid;

[0044] (4) select the mixed cellulose filter membrane that aperture is 220nm for use, adopt the method suction fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com