A cold isostatic pressing method suitable for optical ceramics and a preparation method of optical ceramics

A technology of optical ceramics and cold isostatic pressing, which is applied in the field of optical ceramics, can solve problems such as many defects, uneven force, and reduced ceramic transmittance, and achieve the effects of reducing edge defects, avoiding damage, and high transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The present invention also provides a preparation method of optical ceramics, comprising the following steps:

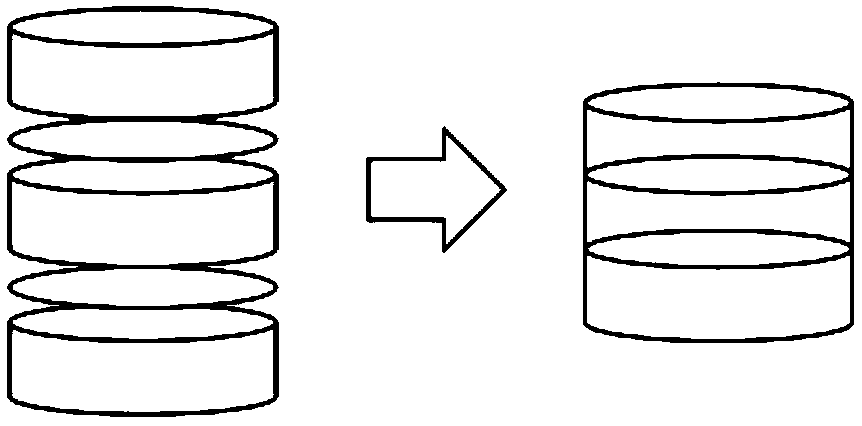

[0050] a) stacking several optical ceramic cylindrical blanks after dry pressing to form a cylinder, and separating each two cylindrical blanks with circular weighing paper;

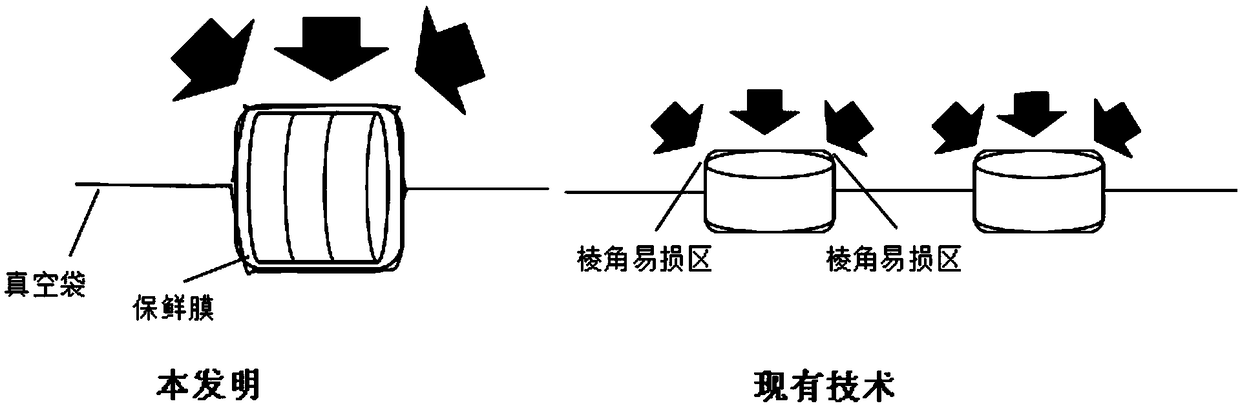

[0051] b) wrapping the stacked cylinder in step a) with plastic wrap for at least 2 layers;

[0052] c) putting the wrapped cylinder in step b) into a vacuum bag to evacuate, then cold isostatic pressing, and obtaining the optical ceramic blank after cold isostatic pressing through decompression;

[0053] d) Calcining, vacuum sintering, annealing and polishing the optical ceramic blank after the cold isostatic pressing in step c) in sequence to obtain the optical ceramic.

[0054] The specific content of the preparation steps for obtaining the optical ceramic green body after cold isostatic pressing in the present invention is as described above, and will not be repeated here.

[0055]...

Embodiment 1

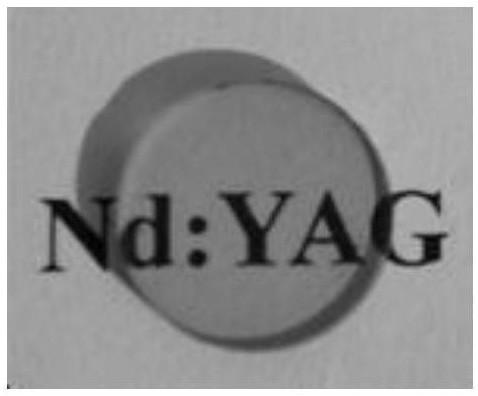

[0061] The present invention prepares the method steps of Nd-doped yttrium aluminum garnet ceramics as follows:

[0062] (1) According to the molar ratio Y:Al=3:5, Nd:Y=1:99, accurately weigh the corresponding amount of Y 2 o 3 、Al 2 o 3 、Nd 2 o 3 Put it into a ball mill jar, add a certain amount of teos as an additive, and alcohol as a ball milling agent. A corresponding amount of high-purity alumina balls was added as ball milling balls, put into a ball mill at a rotational speed of 240 rpm, and ball milled for 960 min. Among them, teos is weighed according to 0.5% of the total powder mass, and alumina balls are added according to the powder: alcohol: ball volume ratio of 1:4:4.

[0063] (2) Put the ball-milled jar into a drying oven and dry at 80° C. for 24 hours, then use a 200-mesh sieve to separate the balls from the powder and sieve the powder.

[0064] (3) Put the sieved powder into a muffle furnace for calcination at 800°C for 3h.

[0065] (4) The calcined pow...

Embodiment 2

[0084] The present invention prepares the method steps of bait-doped yttrium aluminum garnet ceramics as follows:

[0085] (1) Accurately weigh the corresponding amount of Y according to the molar ratio Y:Al=3:5, Er:Y=1:99 2 o 3 、Al 2 o 3 、Er 2 o 3 Put it into a ball mill jar, add a certain amount of teos as an additive, and alcohol as a ball milling agent. A corresponding amount of high-purity alumina balls was added as ball milling balls, put into a ball mill at a rotational speed of 240 rpm, and ball milled for 960 min. Among them, teos is weighed according to 0.5% of the total powder mass, and alumina balls are added according to the powder: alcohol: ball volume ratio of 1:4:4.

[0086] (2) Put the ball-milled jar into a drying oven and dry at 80° C. for 24 hours, then use a 200-mesh sieve to separate the balls from the powder and sieve the powder.

[0087] (3) Put the sieved powder into a muffle furnace for calcination at 800°C for 3h.

[0088] (4) Keep the calcined...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com