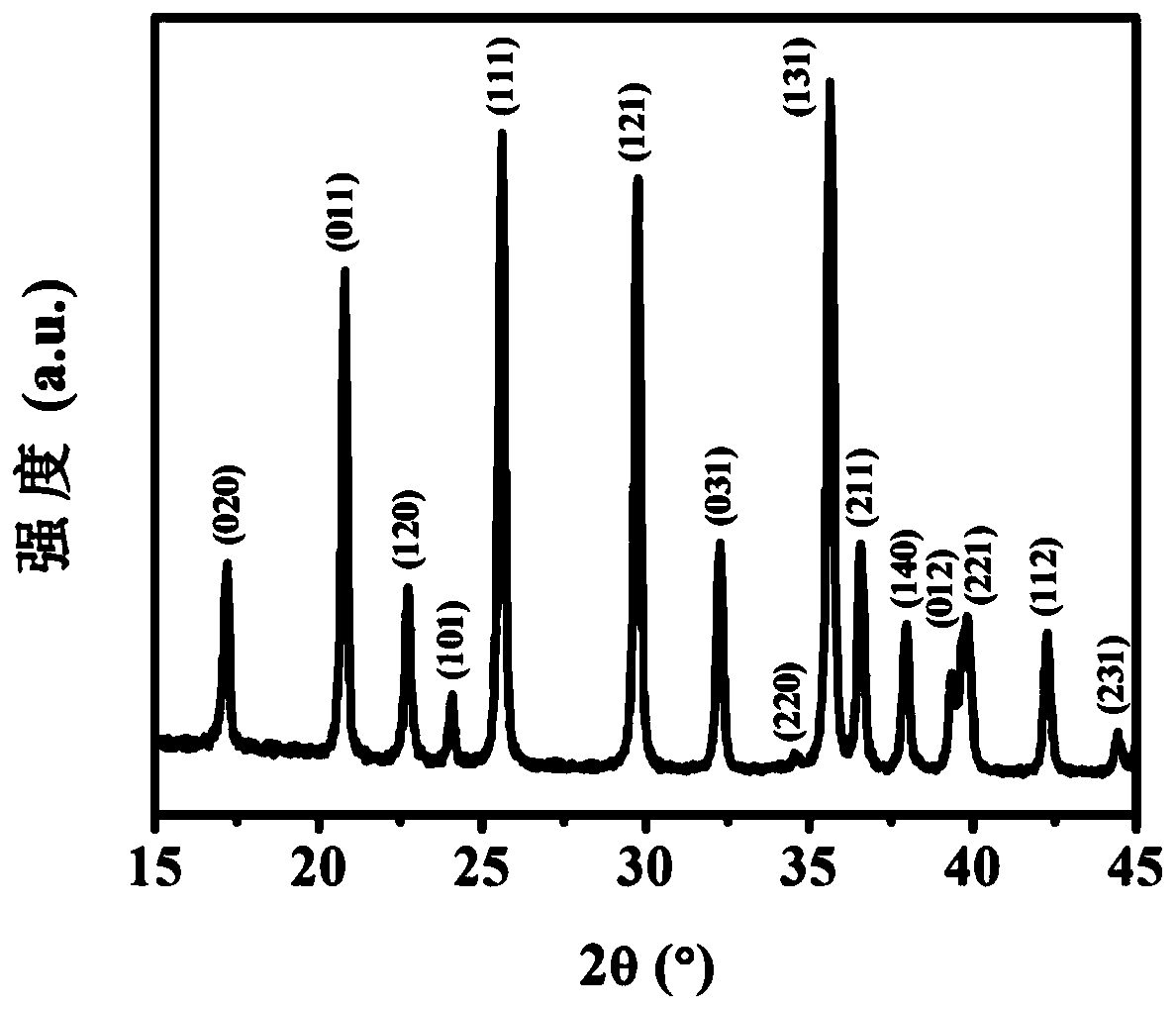

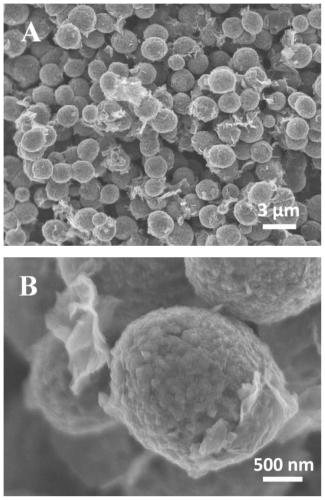

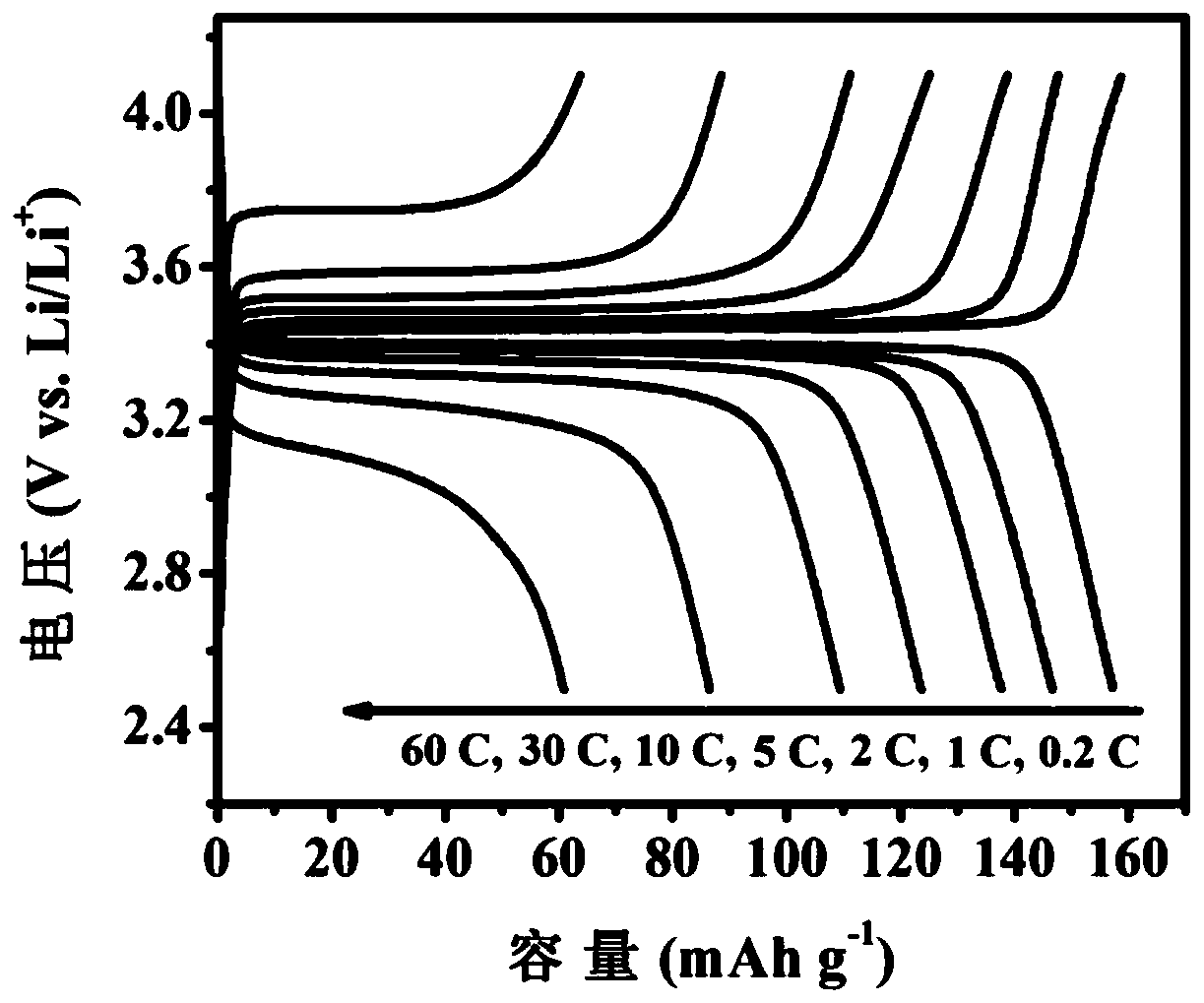

a lifepo 4 Solvothermal Assisted Preparation of @c/rgo Hierarchical Composite Microspheres

A composite microsphere, solvothermal technology, applied in nanotechnology, nanotechnology, structural parts, etc. for materials and surface science, can solve the problem of increasing material production cost and process complexity, low electrical conductivity, and unsuitable scale To solve the problems of popularization and popularization of chemical technology, it can achieve the effect of excellent electrochemical lithium storage performance and improve electronic conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) 1.153g H 3 PO 4 Aqueous solution (H 3 PO 4 The mass fraction is 85%), 0.84g LiOH·H 2 O, 4.04gFe(NO 3 ) 3 9H 2 O and 0.55g resorcinol were sequentially added to 10g, the concentration was 2.0mg mL -1 In the graphene oxide (GO) aqueous solution, fully stir;

[0031] (2) Add 10 g of methanol solution containing 0.81 g of formaldehyde solution (the mass fraction of formaldehyde is 37%) to the solution obtained in step (1), and stir well;

[0032] (3) The mixed solution in step (2) was transferred to a reaction kettle, sealed, and crystallized under autogenous pressure at 180° C. with constant temperature stirring (600 rpm) for 6 hours. After the reaction was completed, the product was suction filtered, washed with deionized water, and air-dried in an oven at 70°C for 12 hours to obtain LiFePO 4 OH@RF / GO powder precursor;

[0033] (4) LiFePO obtained in step (3) 4 OH@RF / GO powder precursor placed in Ar / H 2 (H 2 The volume fraction is 6%) in a tube furnace wi...

Embodiment 2

[0035] (1) 1.153g H 3 PO 4 Aqueous solution (H 3 PO 4 The mass fraction is 85%), 0.84g LiOH·H 2 O, 4.04gFe(NO 3 ) 3 9H 2 O and 0.66g resorcinol were sequentially added to 10g, the concentration was 5.0mg mL -1 In the graphene oxide (GO) aqueous solution, fully stir;

[0036] (2) Add 10 mL of methanol solution containing 1.215 g of formaldehyde aqueous solution (the mass fraction of formaldehyde is 37%) to the solution in step (1), and stir well;

[0037] (3) The mixed solution in step (2) was transferred to a reaction kettle, sealed, and crystallized under autogenous pressure at 170° C. with constant temperature stirring (450 rpm) for 8 hours. After the reaction was completed, the product was suction filtered, washed with deionized water, and dried in an oven at 80°C for 10 hours to obtain LiFePO 4 OH@RF / GO powder precursor;

[0038] (4) LiFePO obtained in step (3) 4 OH@RF / GO powder precursor placed in Ar / H 2 (H 2 The volume fraction is 6%) in a tube furnace with ...

Embodiment 3

[0040] (1) 1.153g H 3 PO 4 Aqueous solution (H 3 PO 4 The mass fraction is 85wt.%), 1.53g CH 3 COOLi·2H 2 O, 4.04g Fe(NO 3 ) 3 9H 2 O and 0.55g resorcinol were sequentially added to 10g, the concentration was 3.0mg mL -1 In the graphene oxide (GO) aqueous solution, fully stir;

[0041] (2) Add 10 g of methanol solution containing 1.215 g of formaldehyde solution (the mass fraction of formaldehyde is 37wt.%) to the solution of step (1), and stir well;

[0042] (3) The mixed solution in step (2) was transferred to a reaction kettle, sealed, and crystallized under autogenous pressure at 200° C. with constant temperature stirring (600 rpm) for 5 hours. After the reaction was completed, the product was suction filtered, washed with deionized water, and dried in an oven at 80°C for 12 hours to obtain LiFePO 4 OH@RF / GO powder precursor;

[0043] (4) LiFePO obtained in step (3) 4 The OH@RF / GO powder precursor was placed in a tube furnace with an Ar atmosphere at 3°C min ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com