Ceramic transforming agent capable of improving corrosion resistance of metal, preparation method and using method thereof

A technology of corrosion resistance and potting agent, applied in the direction of metal material coating process, etc., can solve the problems of limited types of coatings and limited scope of use, and achieve the effects of beautiful appearance, improved bonding, and good electrical conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

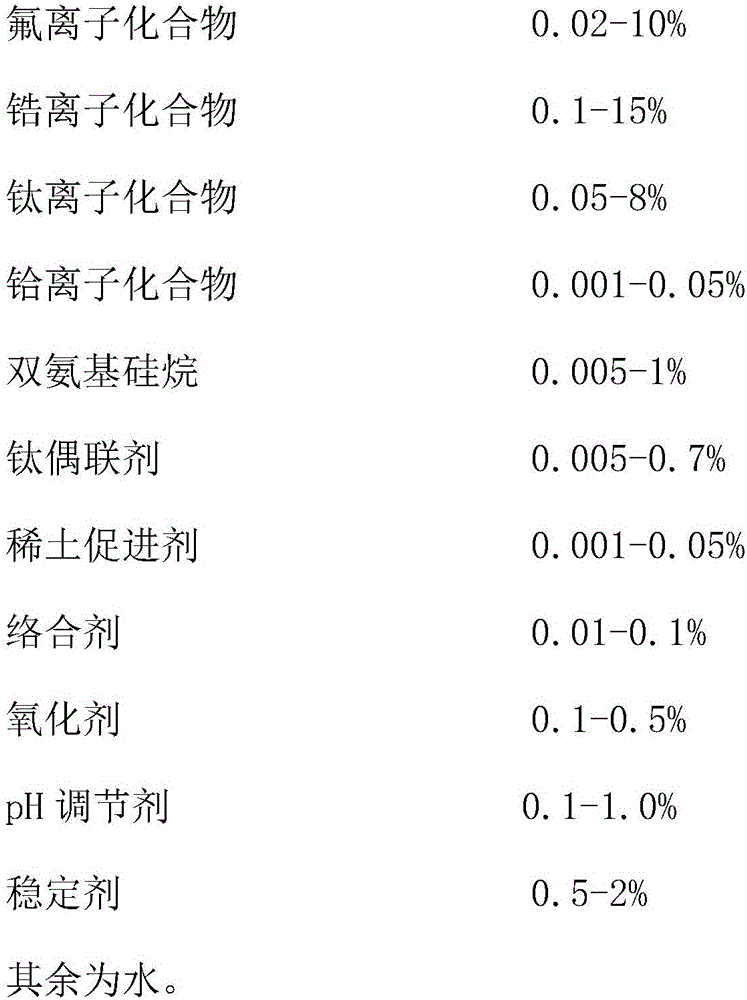

[0044] A vitrifying agent for improving metal corrosion resistance, containing the following raw materials in weight percentage:

[0045]

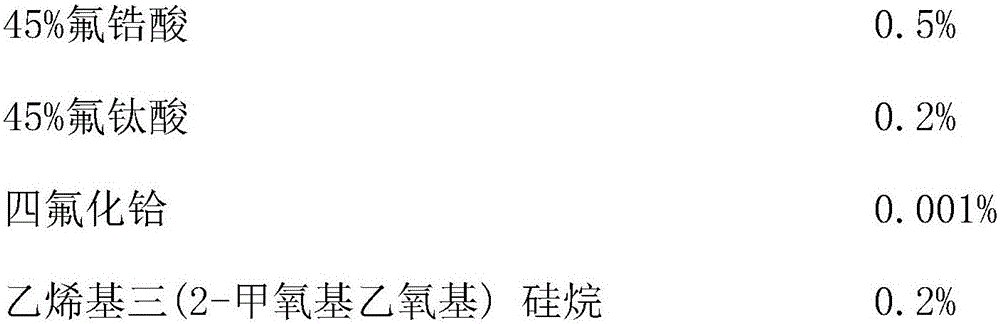

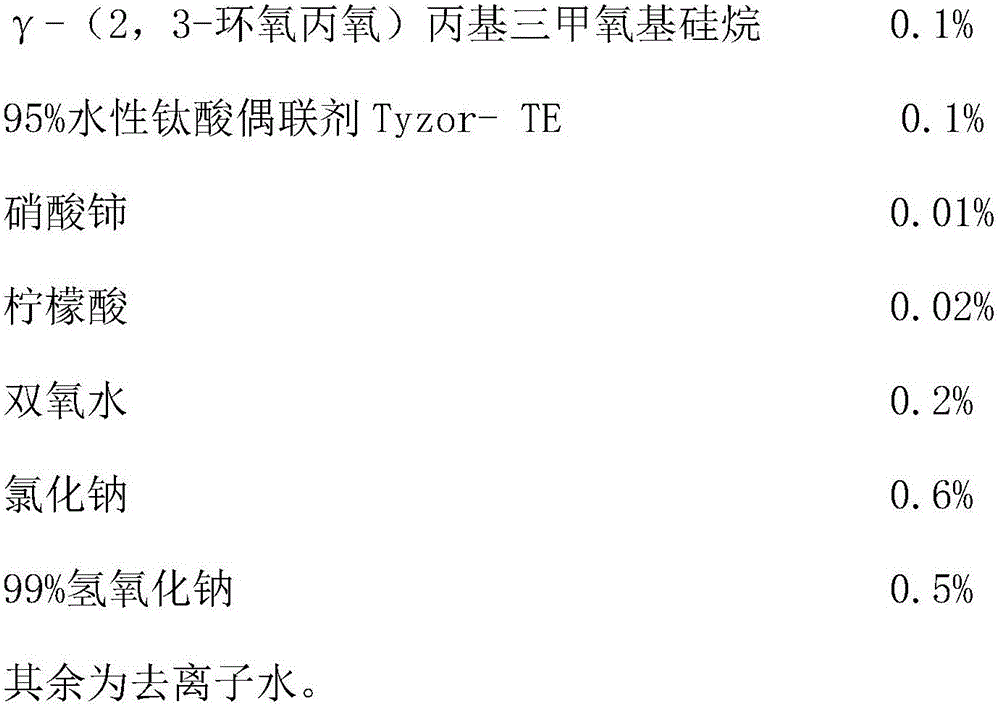

[0046]

[0047] 45% fluorozirconic acid provides both fluoride and zirconium ions; 45% fluorotitanic acid provides both fluoride and titanium ions.

[0048] A preparation method of a vitrifier for improving metal corrosion resistance, comprising the following steps:

[0049] 1) Add two-thirds of the formula amount of deionized water into the reaction kettle, then add the formula amount of 45% fluorozirconic acid, 45% fluorotitanic acid and hafnium tetrafluoride in sequence, and stir well until completely dissolved into a clear solution Add the rare earth accelerator cerium nitrate, complexing agent citric acid and oxidizing agent hydrogen peroxide in the formula amount again, and stir until clear and transparent;

[0050] 2) Add one-tenth of the formula amount of deionized water to another container, heat to 30-40°C, add the formula...

Embodiment 2

[0062] A vitrifying agent for improving metal corrosion resistance, containing the following raw materials in weight percentage:

[0063]

[0064] The ammonium fluorozirconate provides both fluoride and zirconium ions; sodium fluorotitanate provides both fluoride and titanium ions.

[0065] A preparation method of a vitrifier for improving metal corrosion resistance, comprising the following steps:

[0066] 1) Add two-thirds of the formula amount of deionized water into the reaction kettle, then add the formula amount of ammonium fluorozirconate, sodium fluorotitanate and hafnium tetrafluoride in sequence, and stir until it is completely dissolved into a clear solution; Add the rare earth accelerator lanthanum nitrate, the complexing agent potassium sodium tartrate and the oxidant potassium chlorate in the prescribed amount, and stir until it is clear and transparent;

[0067] 2) Add one-tenth of the formula amount of deionized water into another container, heat to 30-40°C...

Embodiment 3

[0079] A vitrifying agent for improving metal corrosion resistance, containing the following raw materials in weight percentage:

[0080]

[0081] Potassium fluozirconate provides both fluoride and zirconium ions; sodium fluotitanate provides both fluoride and titanium ions.

[0082] A preparation method of a vitrifier for improving metal corrosion resistance, comprising the following steps:

[0083] 1) Add two-thirds of the formula amount of deionized water into the reaction kettle, then add the formula amount of potassium fluorozirconate, sodium fluorotitanate and hafnium tetrafluoride in sequence, and stir well until completely dissolved into a clear solution; Add the rare earth accelerator cerium chloride, the complexing agent tartaric acid and the oxidant hydrogen peroxide in the prescribed amount, and stir until it is clear and transparent;

[0084] 2) Add one-tenth of the formula amount of water into another container, heat to 30-40°C, add the formula amount of stab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com