Transmutation glaze ground coat, preparation method thereof and porcelain

A kiln-changing glaze and bottom glaze technology, which is applied in the field of ceramics, can solve problems such as poor viscosity, affecting the quality of the kiln-changing glaze porcelain glaze surface, and restricting promotion, and achieve the effect of changing textures, rich colors, and less environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The embodiment of the present invention provides a kind of kiln underglaze, its components and the mass percentage of each component are: frit 70%~75%, kaolin 5%~8%, zinc oxide 4%~7%, barium carbonate 1% %~2%, ferric oxide 10%~13%.

[0026] According to the bottom glaze prepared by the bottom glaze formula of the present embodiment, its chemical composition includes: SiO 2 , Fe 2 o 3 、Al 2 o 3 , B 2 o 3 、Na 2 O, ZnO, BaO, CaO, K 2 O, Cl, SO 3 ,P 2 o 5 , ZrO 2 , SrO, MnO, PbO, Li 2 O; the percentage by weight of the chemical composition of the bottom glaze is: SiO 2 45%~50%, Fe 2 o 3 10%~13%, Al 2 o 3 10%~12%, B 2 o 3 9%~11%, Na 2 O 6%~8%, ZnO 4%~7%, BaO 1%~2%, CaO 1%~2%, K 2 O 0.4%~1.2%, Cl 0.05%~0.1%, SO 3 0.05%~0.1%, P 2 o 5 0.05%~0.1%, ZrO 2 0.05%~0.1%, SrO 0.01%~0.05%, MnO 0.01%~0.05%, PbO 0.01%~0.05%, Li 2 O <0.01%; its discretion rate is less than 1.50%.

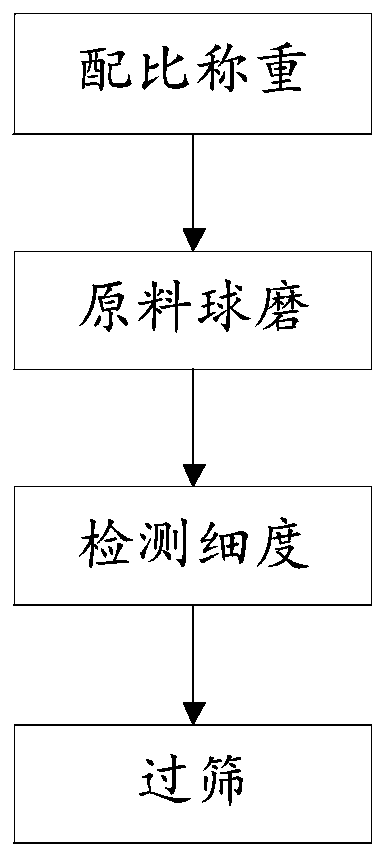

[0027] figure 1 It is a schematic flow chart of the method for preparing kiln und...

Embodiment 2

[0034] The embodiment of the present invention provides a kiln-transformed underglaze, whose components and the mass percentages of each component are: 73.9% of frit, 8.0% of kaolin, 5.0% of zinc oxide, 1.9% of barium carbonate, and 11.2% of ferric oxide.

[0035] According to the bottom glaze prepared by the above bottom glaze formula, the weight percentage of its chemical composition is: SiO 2 49.66%, Fe 2 o 3 11.20%, Al 2 o 3 10.95%, B 2 o 3 10.02%, Na 2 O 7.53%, ZnO 5.00%, BaO 1.85%, CaO 1.28%, K 2 O0.93%, Cl 0.08%, SO 3 0.06%, P 2 o 50.05%, ZrO 2 0.05%, SrO 0.04%, MnO 0.03%, PbO 0.01%, Li 2 O <0.01%; its discretion rate is less than 1.26%

[0036] The preparation method of present embodiment bottom glaze comprises steps:

[0037] Proportion weighing: Proportion weighing according to the raw material formula of the bottom glaze;

[0038] Raw material ball milling: put the prepared bottom glaze raw materials into a ball mill for wet ball milling, the ball mi...

Embodiment 3

[0044] The embodiment of the present invention provides a kiln-transformed underglaze, the components and the mass percentage of each component are: 72.00% of frit, 8.00% of kaolin, 5.74% of zinc oxide, 1.96% of barium carbonate, and 12.30% of ferric oxide.

[0045] According to the bottom glaze prepared by the above bottom glaze formula, the weight percentage of its chemical composition is: SiO 2 48.76%, Fe 2 o 3 12.30%, Al 2 o 3 10.2%, B 2 o 3 10.02%, Na 2 O 7.25%, ZnO 5.74%, BaO 1.96%, CaO 1.32%, K 2 O0.93%, Cl 0.08%, SO 3 0.06%, P 2 o 5 0.04%, ZrO 2 0.05%, SrO 0.03%, MnO 0.02%, PbO 0.01%, Li 2 O <0.01%; its discretion rate is less than 1.25%.

[0046] The preparation method of present embodiment bottom glaze comprises steps:

[0047] Proportion weighing: Proportion weighing according to the raw material formula of the bottom glaze;

[0048] Raw material ball milling: put the prepared bottom glaze raw materials into a ball mill for wet ball milling, the ball...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com