Automobile die manufacturing process

A manufacturing process and a technology for automobile molds, applied in the field of automobile mold manufacturing technology, can solve the problems of reducing the economic benefits of automobile mold manufacturers, long production cycle, poor use strength, etc., to shorten the production cycle, improve the service life, and improve the use strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

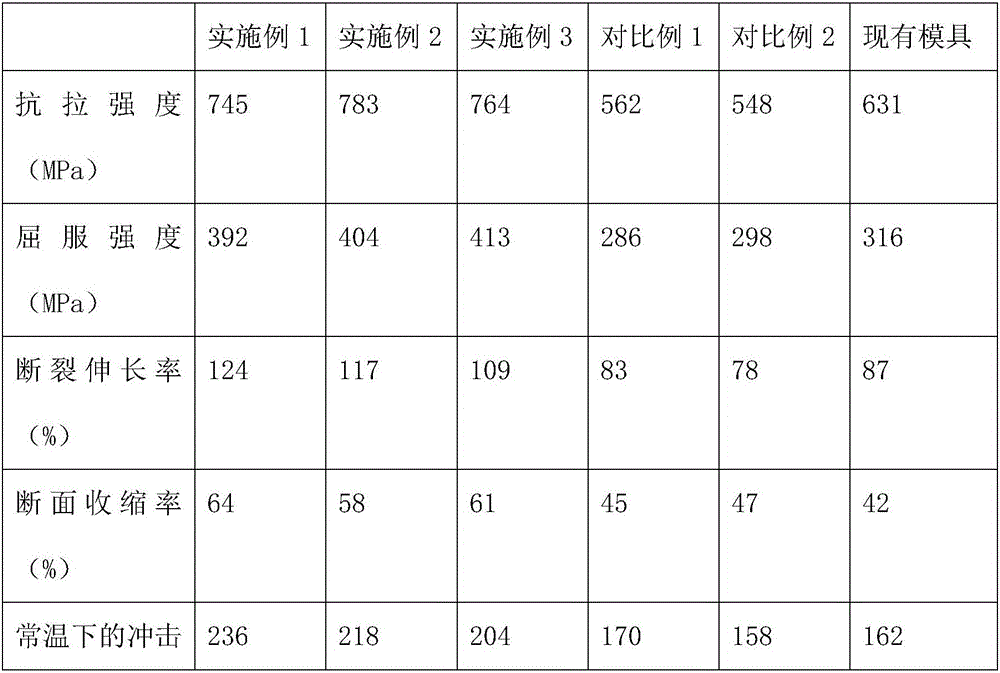

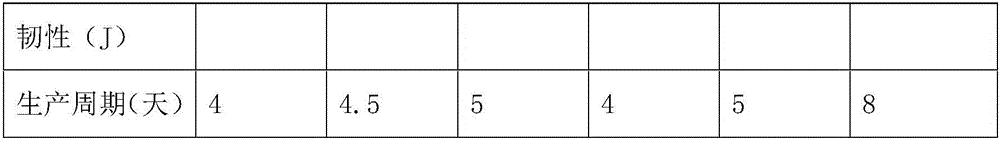

Examples

Embodiment 1

[0017] A process for making automobile molds, the specific steps are as follows:

[0018] Step 1: Put the mold steel in a melting furnace, add silicon carbide fiber with a weight of 1% of the mold steel and glass fiber with a weight of 3% of the mold steel into the melting furnace, and put the mixture in the melting furnace Heat until the die steel is completely austenitized, hold for 5 hours, cool the furnace to 280°C, hold for 3 hours, then heat to 650°C, hold for 10 hours, cool to 400°C at a rate of 43°C / hour, and then at 20°C Cool to room temperature at a rate of 1 hour per hour, heat the mixture to 980°C and keep it for 1 hour. After the oil cools to 75°C, reheat to 680°C and keep it for 3 hours, then water cooling; after water cooling, use low temperature tempering treatment, and then The head of the mixture is heated to 280°C for 4 hours, and then spray cooling is performed. The tail of the mixture is held at 900°C for 6 hours, then air-cooled. Finally, the middle part of ...

Embodiment 2

[0025] A process for making automobile molds, the specific steps are as follows:

[0026] Step 1: Put the mold steel in a melting furnace, and add silicon carbide fiber that weighs one-fifth of the mold steel and glass fiber that weighs one-fifth of the mold steel into the melting furnace. The mixture is heated until the mold steel is completely austenitized, kept for 5.5 hours, the furnace is cooled to 295°C, kept for 4 hours, then heated to 675°C, kept for 12 hours, cooled to 400°C at a rate of 43°C / hour, and then Cool to room temperature at a rate of 20°C / hour, heat the mixture to 980°C and keep it for 1.5 hours. After oil cooling to 60°C, reheat to 695°C and keep it for 5 hours, then water cooling; after water cooling, use low temperature tempering treatment , Then heat the head of the mixture to 330°C for 4.5 hours, and then spray cooling treatment. The tail of the mixture is held at 960°C for 6 hours and then air-cooled. Finally, the middle part of the mixture is heated to ...

Embodiment 3

[0033] A process for making automobile molds, the specific steps are as follows:

[0034] Step 1: Put the mold steel in a melting furnace, and add silicon carbide fiber with a weight of one twentieth of the mold steel and glass fiber with a weight of 3% of the mold steel into the melting furnace. The mixture is heated until the mold steel is completely austenitized, kept for 6 hours, the furnace is cooled to 320°C, kept for 5 hours, then heated to 690°C, kept for 15 hours, cooled to 400°C at a rate of 43°C / hour, and then heated to 20°C. Cool to room temperature at a rate of ℃ / hour, heat the mixture to 980℃ and keep it for 1.5 hours. After oil cooling to 80℃, reheat to 710℃ and keep it for 4 hours, then water cooling; after water cooling, use low temperature tempering treatment, and then Heat the head of the mixture to 360°C for 5 hours, and then spray cooling. The tail of the mixture is held at 1020°C for 8 hours, then air-cooled. Finally, the middle part of the mixture is heated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com