Toughened, modified, low-temperature-cued and low-glossiness powder coating, preparation method and application

A low-gloss, toughening modification technology, used in low-temperature curing, impact-resistant powder coatings, high-toughness, preparation, low-gloss fields, can solve problems such as poor impact performance, and improve bending resistance and impact resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

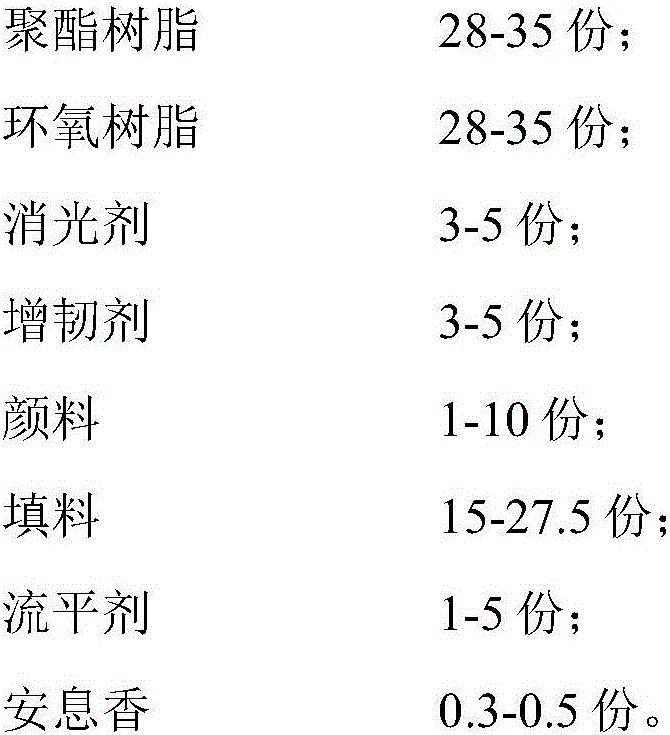

[0036] A toughened modified low-temperature curing low-gloss powder coating, comprising the following components by weight:

[0037]

[0038] First, accurately weigh the raw materials according to the formula composition of the coating components, and mix them evenly in the premixing tank through high-speed rotation (premixing time is 5-10 minutes), and then put the evenly mixed raw materials into the twin-screw extruder at a constant speed. The extruder is melted and extruded under the condition of 95-105°C, passed through the cooling roller and pressed into tablets, the tablets are cooled at natural temperature, and the flakes are roughly crushed by a pulverizer, and the obtained materials are ground by a pulverizer after cooling Fine grinding; in order to increase the dry powder fluidity of the powder and prevent powder agglomeration during the grinding process, add 0.1 part of desiccant AEROSIL Alu C, and then use a 180-mesh sieve to sieve, and finally get all the powder...

Embodiment 2

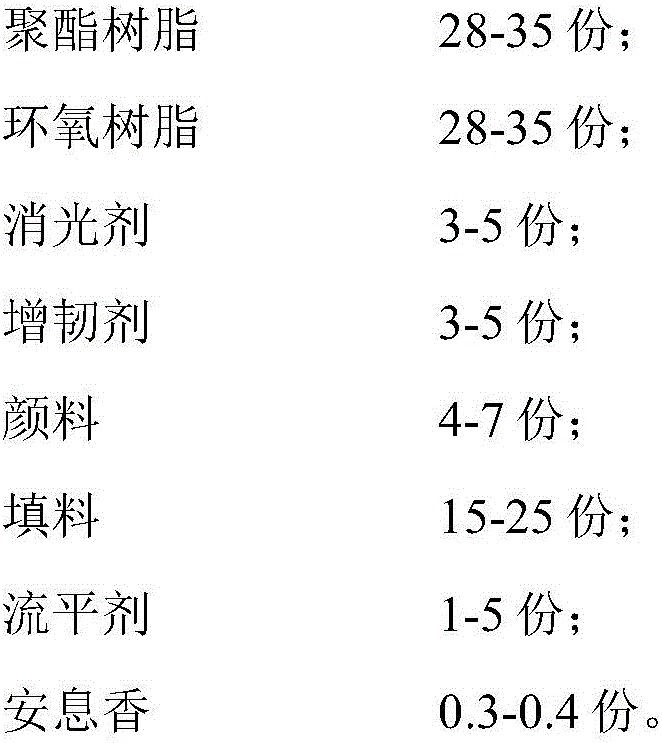

[0040] A toughened modified low-temperature curing low-gloss powder coating, comprising the following components by weight:

[0041]

[0042] First, accurately weigh the raw materials according to the formula composition of the coating components, and mix them evenly in the premixing tank through high-speed rotation (premixing time is 5-10 minutes), and then put the evenly mixed raw materials into the twin-screw extruder at a constant speed. The extruder is melted and extruded under the condition of 95-105°C, passed through the cooling roller and pressed into tablets, the tablets are cooled at natural temperature, and the flakes are roughly crushed by a pulverizer, and the obtained materials are ground by a pulverizer after cooling Fine grinding; in order to increase the dry powder fluidity of the powder and prevent powder agglomeration during the grinding process, add 0.1 part of desiccant AEROSIL Alu C, and then use a 180-mesh sieve to sieve, and finally get all the powder...

Embodiment 3

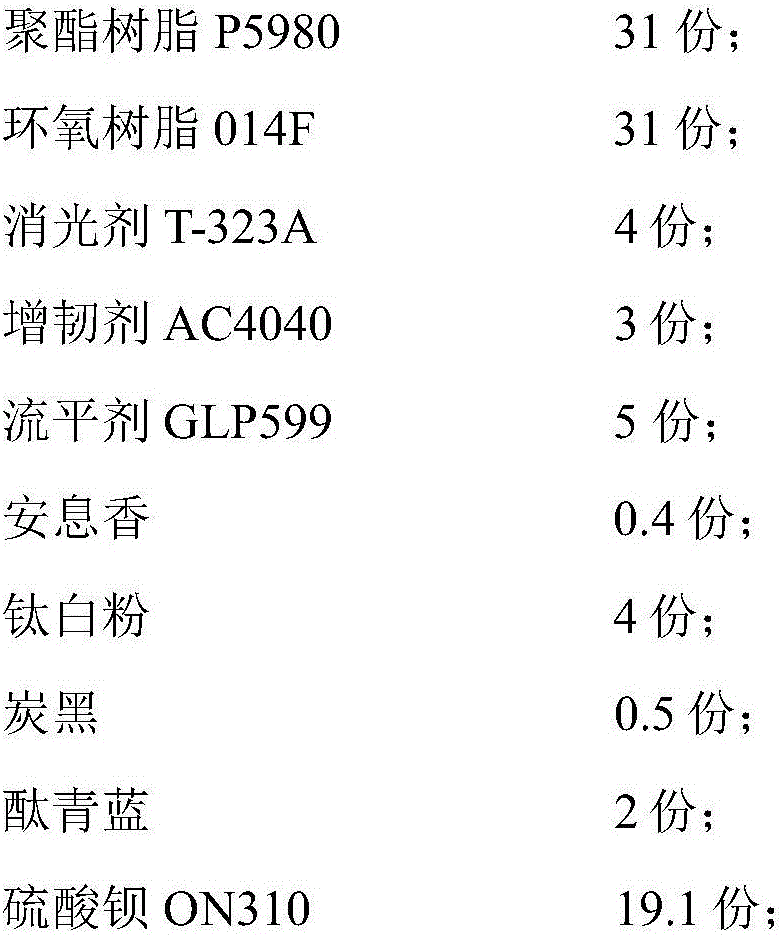

[0044] A toughened modified low-temperature curing low-gloss powder coating, comprising the following components by weight:

[0045]

[0046]

[0047]First, accurately weigh the raw materials according to the formula composition of the coating components, and mix them evenly in the premixing tank through high-speed rotation (premixing time is 5-10 minutes), and then put the evenly mixed raw materials into the twin-screw extruder at a constant speed. The extruder is melted and extruded under the condition of 95-105°C, passed through the cooling roller and pressed into tablets, the tablets are cooled at natural temperature, and the flakes are roughly crushed by a pulverizer, and the obtained materials are ground by a pulverizer after cooling Fine grinding; in order to increase the dry powder fluidity of the powder and prevent powder agglomeration during the grinding process, add 0.1 part of desiccant AEROSIL Alu C, and then use a 180-mesh sieve to sieve, and finally get all...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com