Polyester modified aqueous acrylic resin, preparation method thereof, and application thereof in varnish

A water-based acrylic and polyester modification technology, applied in the direction of coating, can solve the problems of difficult acquisition of raw materials, no introduction of water-based acrylic resin synthesis, high cost, and achieve the effects of low cost, high fullness, and easy raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

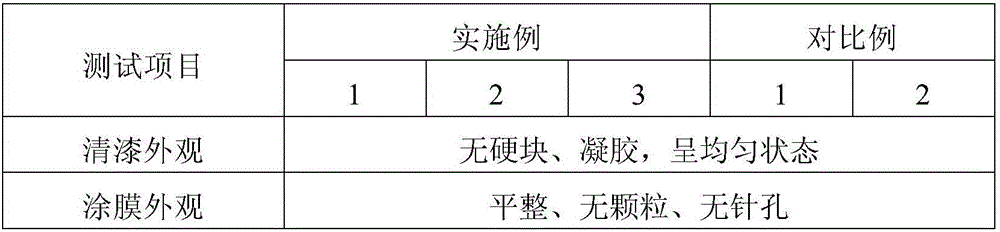

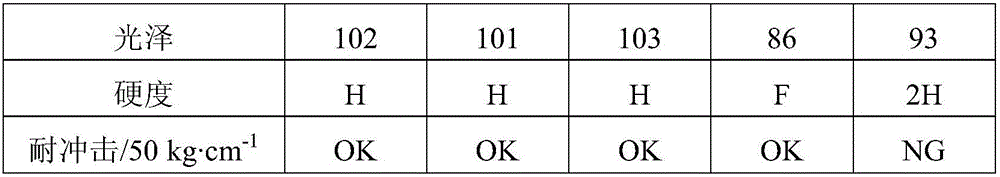

Examples

Embodiment 1

[0046] Embodiment 1: the preparation of polyester modified waterborne acrylic resin

[0047] 180g ethylene glycol, 1452g neopentyl glycol, 708g 1,4-cyclohexanedicarboxylic acid, 672g isophthalic acid, 335.2g adipic acid and 208.8g fumaric acid, 3.0g dibutyltin dilaurate , put into the reactor that agitator, thermometer, rectifying column, condenser and nitrogen inlet are equipped with, reaction temperature is 230 ℃, pressure 0.11MPa, stirs 10 hours, regulates pressure to-0.095MPa, and reaction temperature is 190 ℃, Stir for 6 hours, take samples to measure acid value and viscosity. React until the acid value is 12mgKOH / g, cool down to 120°C, add 2000g ethylene glycol monobutyl ether to adjust the solid content to 60±2%, and measure the viscosity with a rotational viscometer at 25°C to be 5000-6000mPa.s, the degree of unsaturation (Expressed by iodine value, in terms of non-volatile matter) is 13.5, the glass transition temperature is -20 ℃, and the unsaturated polyester is ob...

Embodiment 2

[0049] Embodiment 2: the preparation of polyester modified waterborne acrylic resin

[0050] 250g neopentyl glycol, 792g 1,4-cyclohexanedimethanol, 200g 1,6-hexanediol, 242g terephthalic acid, 625g adipic acid, 417g isophthalic acid, 150g fumaric acid, 3g Titanate, put into the reaction kettle equipped with stirrer, thermometer, rectification column, condenser and nitrogen inlet, the reaction temperature is 220 ℃, the pressure is 0.11MPa, stir for 10 hours, adjust the pressure to -0.095MPa, the reaction temperature It is 180°C, stir for 5 hours, take a sample to measure the acid value and viscosity, react until the acid value is 18mgKOH / g, cool down to 120°C, add 1450g ethylene glycol monobutyl ether to adjust the solid content to 60±2%, and use a rotary at 25°C The viscosity measured by the viscometer is 3500-5000mPa.s, the degree of unsaturation (indicated by iodine value, in terms of non-volatile matter) is 12.0, and the glass transition temperature is -10°C, and the unsatura...

Embodiment 3

[0052] Embodiment 3: the preparation of polyester modified waterborne acrylic resin

[0053] 320g hexanediol, 700g neopentyl glycol, 600g 1,4-cyclohexanedimethanol, 370g trimellitic anhydride, 100g hexahydrophthalic anhydride, 500g 1,4-cyclohexanedicarboxylic acid, 550g isophthalic acid, 130g cis Butenedioic anhydride, 8g ethylene glycol antimony, put into the reaction kettle equipped with stirrer, thermometer, rectifying column, condenser and nitrogen inlet, the reaction temperature is 250 ℃, the pressure is 0.12MPa, stir for 6 hours, adjust the pressure to -0.095MPa, the reaction temperature is 200°C, stirred for 3 hours, and samples are taken to measure the acid value and viscosity. React until the acid value is 25mgKOH / g, cool down to 120°C, add 1780g ethylene glycol monobutyl ether to adjust the solid content to 60±2%, and measure the viscosity with a rotational viscometer at 25°C to be 1500-3500mPa.s, the degree of unsaturation (Expressed by iodine value, in terms of no...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com