Method for preparing spherical organic micro-molecular monomer or compound through emulsion technology

A small molecule monomer, spheroidization technology, applied in the direction of organic chemistry, granulation of raw materials, organic active ingredients, etc., to achieve the effect of improving fluidity, reducing sensitivity and cost-effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Step 1. Feed with hexanitrohexaazaisowurtzitane (CL-20) / p-nitrochlorobenzene (PNCB)=1:3 molar ratio, weigh 0.438g of CL-20 and 0.479g of PNCB respectively Add it to a reaction flask containing 5mL of ethyl acetate, then add 16mL of distilled water, then put it in a stirrer at 40°C and stir at 1000rpm, add 2×10 -4 g surfactant gelatin, after the emulsion is uniformly dispersed, carry out ultrasonic emulsification with a power of 1200W for 60min to obtain a uniformly dispersed emulsion; adopt the method of adding non-solvent ethanol extraction to allow crystals to separate out to obtain a solid-liquid mixture; the non-solvent ethanol The dosage is 10 times the mass of the solute;

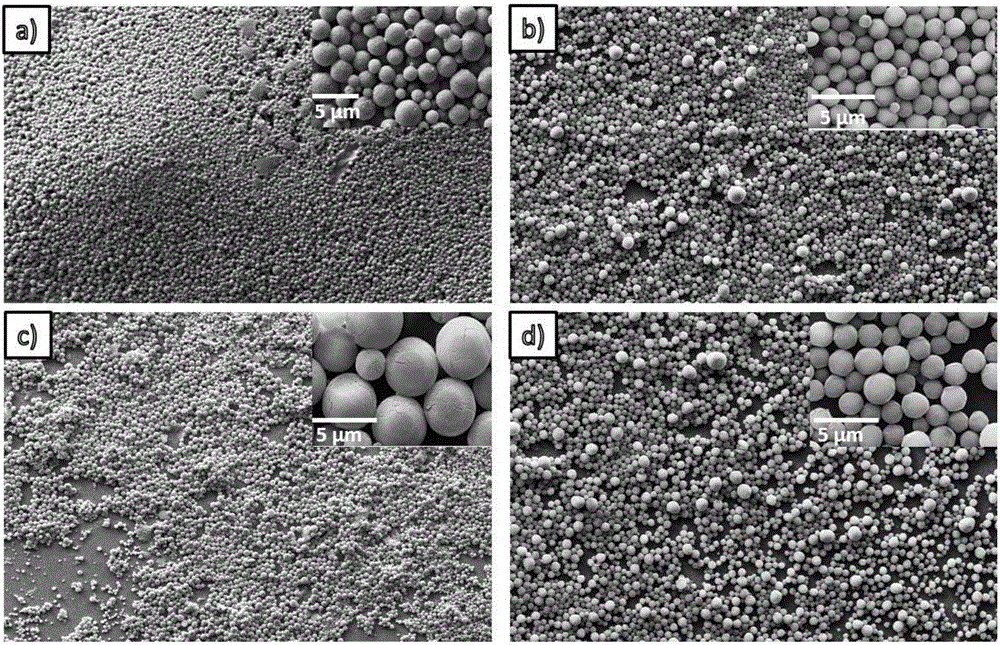

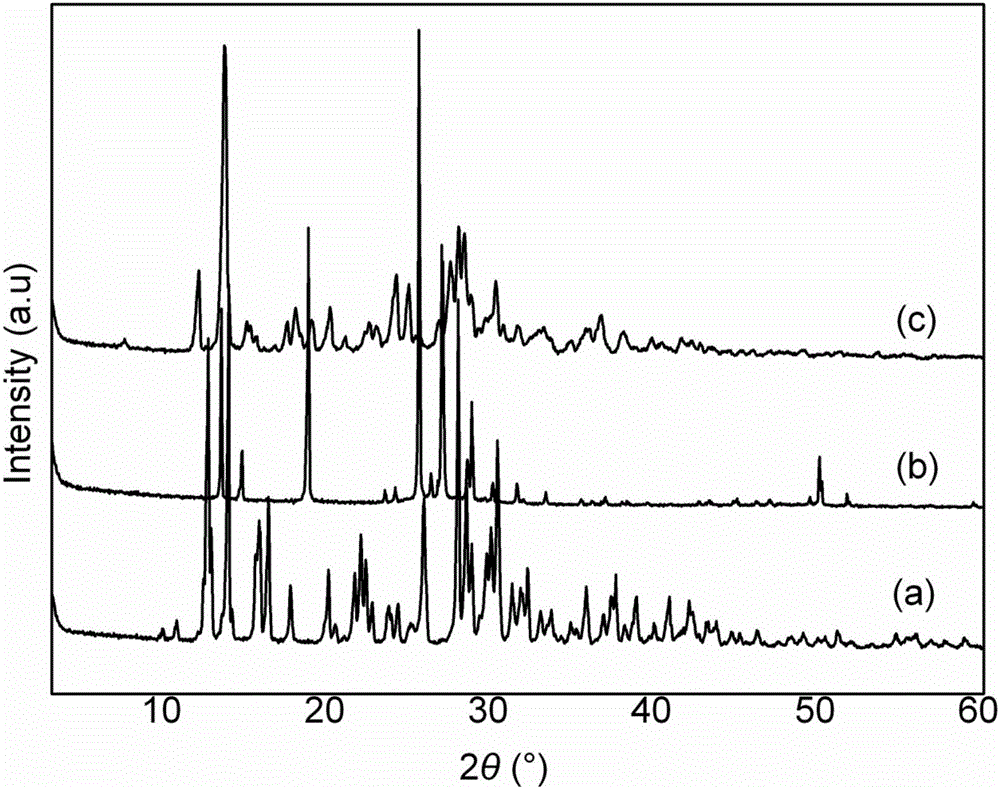

[0030] Step 2, filtering, washing and drying the solid-liquid mixture to obtain complex spherical crystals; figure 1 c) SEM schematic of the CL-20 / PNCB complex co-crystal is shown; from figure 1 It can be seen from the figure that the particle size distribution of the CL-20 / PNCB composite eut...

Embodiment 2

[0032] Step 1. Feed materials at a molar ratio of CL-20 / 2,4,6-trinitrotoluene (TNT) / PNCB=1:2:3, and weigh 0.438g CL-20, 0.2g TNT and 0.479g PNCB respectively Add it into a reaction flask containing 7mL of ethyl acetate, then add 28mL of water, then put it in a stirrer at 40°C and stir at 800rpm, add 1.5×10 -4 g surfactant gelatin, after the emulsion is uniformly dispersed, carry out ultrasonic emulsification for 60min with a power of 1200W to obtain a uniformly dispersed emulsion; adopt the method of adding non-solvent ethanol extraction to allow crystals to separate out; obtain a solid-liquid mixture; the non-solvent ethanol The dosage is 15 times the mass of the solute;

[0033] Step 2, the solid-liquid mixture is filtered, washed and dried to obtain complex spherical crystals.

Embodiment 3

[0035] Step 1. Feed materials at a molar ratio of CL-20 / PNCB=1:3, weigh 0.438g of CL-20 and 0.479g of PNCB respectively and add them to a reaction bottle containing 7mL of ethyl acetate, then add 28mL of water , and then placed in a stirrer at 40 ° C with 1000rpm stirring, adding 4 × 10 -4 g surfactant gelatin, after the emulsion is uniformly dispersed, perform ultrasonic emulsification with a power of 1200W for 60 minutes to obtain a uniformly dispersed emulsion; use the method to raise the temperature to 90°C to allow crystals to precipitate; obtain a solid-liquid mixture;

[0036] Step 2, the solid-liquid mixture is filtered, washed and dried to obtain complex spherical crystals.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com