Injectable temperature-sensitive magnetic nano emulsive gel and preparation method and application thereof

A magnetic nano-gel technology, applied in biological and medical nano-materials and fields, can solve the problems of dispersion, damage to normal tissues, affecting the treatment effect, etc., and achieve the effects of excellent heating performance, prolonging survival period and good appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

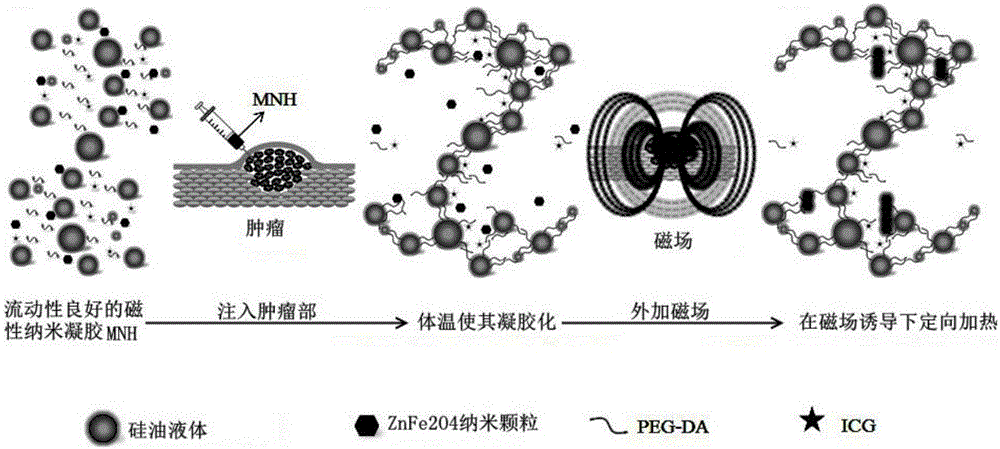

[0029] The main steps of the preparation method of the injectable temperature-sensitive magnetic nanoemulsion gel of the present invention are: adding oil-soluble ZnFe 2 O 4 The nanoparticles are added to the silicone oil to fully disperse the nanoparticles, and the resulting mixture serves as the oil phase. The oil phase is added dropwise to boiling water dissolved with the surfactant sodium lauryl sulfate under stirring to obtain colostrum, and then ultrasonically emulsified with an ultrasonic cell disruptor to obtain a stable oil-in-water magnetic nanoemulsion. Then, the liquid PEG-DA (polyethylene glycol diacrylate) is added dropwise to the magnetic nanoemulsion under low temperature conditions, and the ultrasonic dispersion makes the PEG-DA molecules fully dispersed between the magnetic nanoemulsions to obtain the magnetic nanoemulsion. Emulsion gel, stored at 4 degrees low temperature.

[0030] Among them, ZnFe in the oil phase 2 O 4 The nano-particle size is between 10-20 ...

Embodiment 1

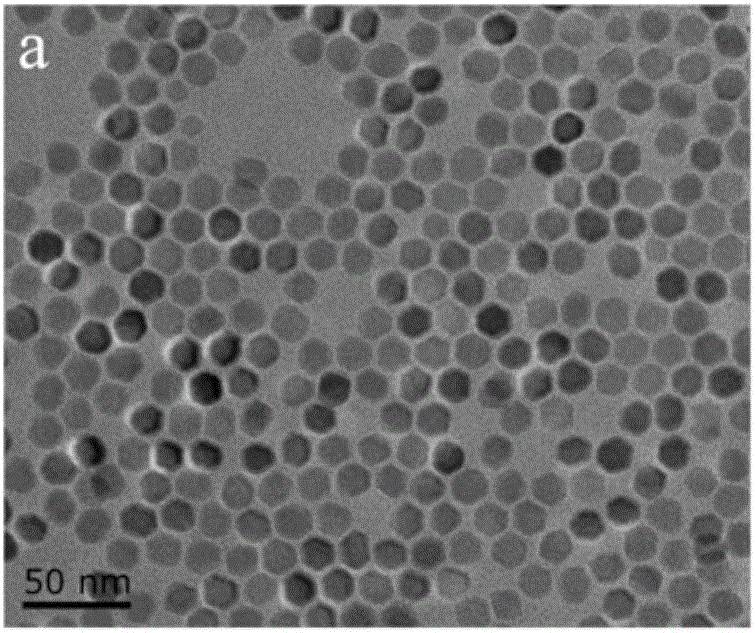

[0034] Preparation of ZnFe by high temperature thermal decomposition method 2 O 4 Nanoparticles

[0035] Add 2mmol of iron acetylacetonate, 1mmol of zinc acetylacetonate, 20mL of reaction solvent dibenzyl ether, and 12mmol of surfactants oleic acid and oleylamine in a 100ml three-necked flask with a beveled neck. Oxygen also plays a role of stirring, while condensing and refluxing. Heat the reaction system to a nucleation temperature of 220°C at a heating rate of 3.3°C / min through a programmed temperature control device, and keep the temperature for 1 hour. This stage is the nucleation stage of magnetic iron oxide nanoparticles. During the process, the solution turns from brownish red to red. Translucent black. Then, the reaction system was still heated to a growth temperature of 290°C at a heating rate of 3.3°C / min, and the reaction system was maintained at this temperature for 30 minutes to complete the reaction. After the reaction is over, remove the heat source. After the r...

Embodiment 2

[0038] Preparation of magnetic nanoemulsion gel

[0039] The oil-soluble ZnFe prepared in Example 1 2 O 4 Add 10 mg of the nano particles in terms of iron to 2 ml of silicone oil, and mix the nano particles and the silicone oil thoroughly with a vortex, and the resulting mixture is used as the oil phase. The oil phase was added dropwise to boiling water with 200 mM sodium lauryl sulfate dissolved in a stirring state at a rotational speed of 600 r / min, and stirring was continued for 30 minutes, and the volume was dilute to 4 ml with ultrapure water to obtain colostrum. A stable oil-in-water magnetic nanoemulsion was obtained by ultrasonic emulsification and dispersion for 30 minutes with an ultrasonic cell disruptor with a power of 300w. Then add 2ml of liquid PEG-DA dropwise to the magnetic nanoemulsion under low temperature conditions, and 100w power ultrasonic dispersion makes the PEG-DA molecules fully dispersed between the magnetic nanoemulsions to obtain the magnetic nanoemu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Saturation magnetization value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com