Automobile anticorrosive coating and preparation method thereof

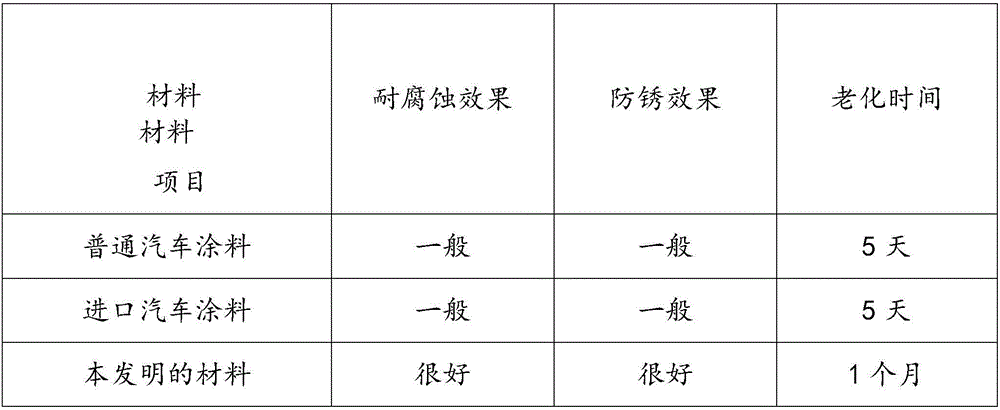

A technology for anti-corrosion coatings and automobiles. It is applied in the direction of anti-corrosion coatings, polyester coatings, epoxy resin coatings, etc. It can solve the problems of anti-aging, coatings that do not have corrosion resistance, and anti-rust effects that cannot be achieved. long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] An anti-corrosion coating for automobiles, made of the following materials in parts by weight, including 46 parts of epoxy resin, 19 parts of zinc phosphate, 20 parts of lead soap, 10 parts of coal tar, 9 parts of phytate, chlorinated 5 parts of paraffin wax, 16 parts of castor bean wax, 12 parts of activated carbon, 7 parts of zeolite, 11 parts of alkyd resin, 20 parts of sodium lauryl sulfate, 6 parts of trichlorofluoromethane, 11 parts of ethylene glycol ether acetate, toluene 3 parts of sulfonic acid, 8 parts of aluminum tripolyphosphate, 7 parts of propylene glycol methyl ether, 4 parts of micaceous iron oxide, 9 parts of silicon dioxide powder and 4 parts of siloxane.

[0019] A preparation method for automobile anticorrosion paint, comprising the following steps:

[0020] 1) 46 parts of epoxy resin, 19 parts of zinc phosphate, 20 parts of lead soap, 10 parts of coal tar, 9 parts of phytic acid ester, 5 parts of chlorinated paraffin, 16 parts of castor bean wax, 1...

Embodiment 2

[0026] An anti-corrosion coating for automobiles, made of the following materials in parts by weight, including 52 parts of epoxy resin, 19.5 parts of zinc phosphate, 21 parts of lead soap, 12.5 parts of coal tar, 10.5 parts of phytate, chlorinated 7.5 parts of paraffin wax, 18 parts of castor bean wax, 14 parts of activated carbon, 8 parts of zeolite, 12.5 parts of alkyd resin, 22.5 parts of sodium lauryl sulfate, 8 parts of trichlorofluoromethane, 12.5 parts of ethylene glycol ether acetate, toluene 5.5 parts of sulfonic acid, 9 parts of aluminum tripolyphosphate, 7.5 parts of propylene glycol methyl ether, 6 parts of micaceous iron oxide, 10.5 parts of silicon dioxide powder and 4.5 parts of siloxane.

[0027] A preparation method for automobile anticorrosion paint, comprising the following steps:

[0028] 1) 52 parts of epoxy resin, 19.5 parts of zinc phosphate, 21 parts of lead soap, 12.5 parts of coal tar, 10.5 parts of phytic acid ester, 7.5 parts of chlorinated paraffi...

Embodiment 3

[0034]An anti-corrosion coating for automobiles, made of the following materials in parts by weight, including 58 parts of epoxy resin, 20 parts of zinc phosphate, 22 parts of lead soap, 15 parts of coal tar, 12 parts of phytate, chlorinated 10 parts of paraffin wax, 20 parts of castor bean wax, 16 parts of activated carbon, 9 parts of zeolite, 14 parts of alkyd resin, 25 parts of sodium lauryl sulfate, 10 parts of trichlorofluoromethane, 14 parts of ethylene glycol ether acetate, toluene 8 parts of sulfonic acid, 10 parts of aluminum tripolyphosphate, 8 parts of propylene glycol methyl ether, 8 parts of micaceous iron oxide, 12 parts of silicon dioxide powder and 5 parts of siloxane.

[0035] A preparation method for automobile anticorrosion paint, comprising the following steps:

[0036] 1) 58 parts of epoxy resin, 20 parts of zinc phosphate, 22 parts of lead soap, 15 parts of coal tar, 12 parts of phytic acid ester, 10 parts of chlorinated paraffin, 20 parts of castor bean ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com