High-heat-resistance high-impact PA/ABS alloy material

An alloy material, high impact technology, applied in the field of high heat resistance and high impact PA/ABS alloy material, to achieve the effect of high impact, high heat resistance and improved heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

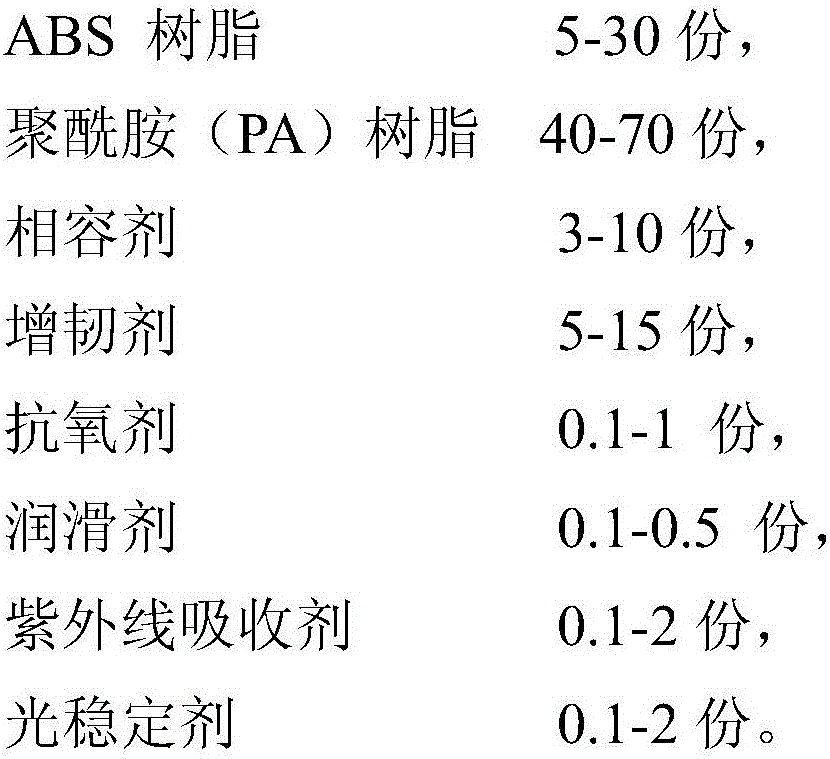

Image

Examples

Embodiment 1

[0036] 70 parts by weight of PA6; 10 parts of ABS; 5 parts of compatibilizer S601N; 14 parts of toughening agent NG7002; 0.2 part of antioxidant 1098; 0.2 part of antioxidant 168; Parts; 0.2 parts of light stabilizer UV944, dry mixed in a high-speed mixer at room temperature for 5 minutes, then added to a twin-screw extruder, melt extruded, granulated to make a composite material.

[0037] The heating zones of the screw are set as follows: Zone 1 200°C, Zone 2 230°C, Zone 3 230°C, Zone 4 230°C, Zone 5 230°C, Zone 6 230°C, Zone 7 230°C, Zone 8 230°C, The machine head is at 230°C, and the screw speed is 200r / min.

Embodiment 2-6

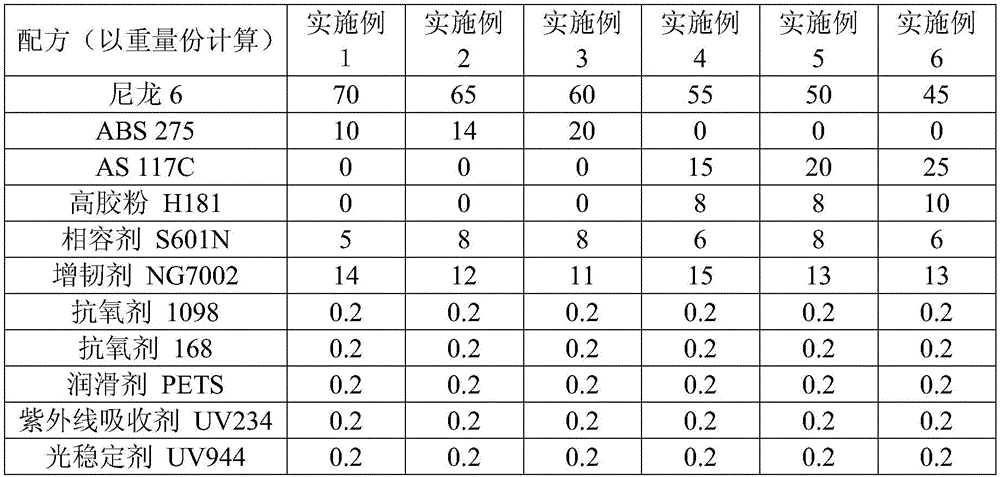

[0039] The raw materials were weighed according to the parts by weight in Table 1, and the preparation method was the same as in Example 1.

[0040] Components and proportioning of table 1 embodiment 1-6

[0041]

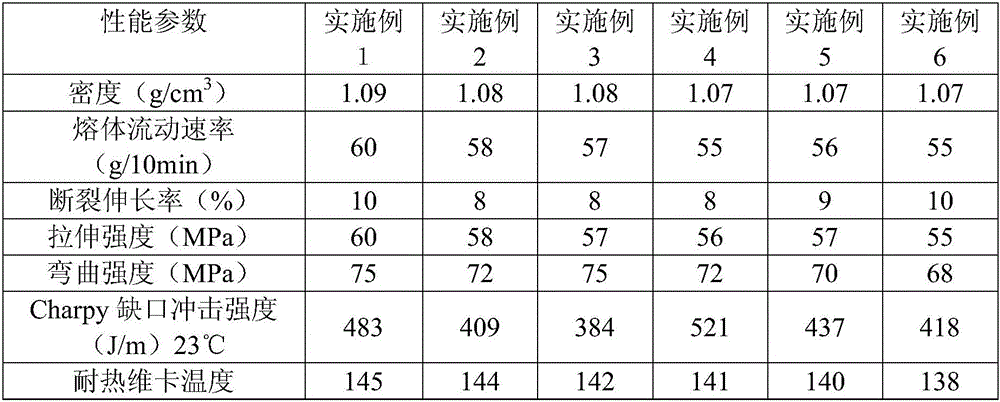

[0042] Evaluation of Implementation Effect

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vicat softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com