Method for preparing inorganic nanoparticle/polyethylene copolymer composite material

An inorganic nanoparticle and polyethylene copolymer technology, which is applied in the field of preparation of inorganic nanoparticle/polyethylene copolymer composite materials, can solve the problems of inability to make fine daily necessities, affect processing performance, reduce toughness, etc., achieve high toughness, improve Mechanical strength, effect of reducing crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

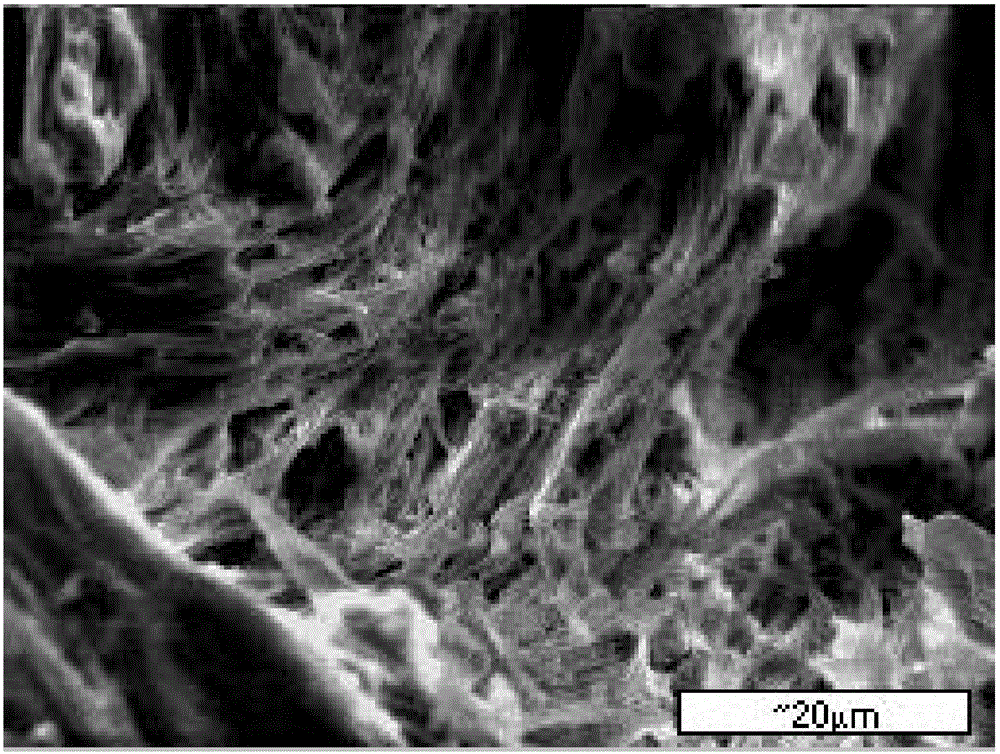

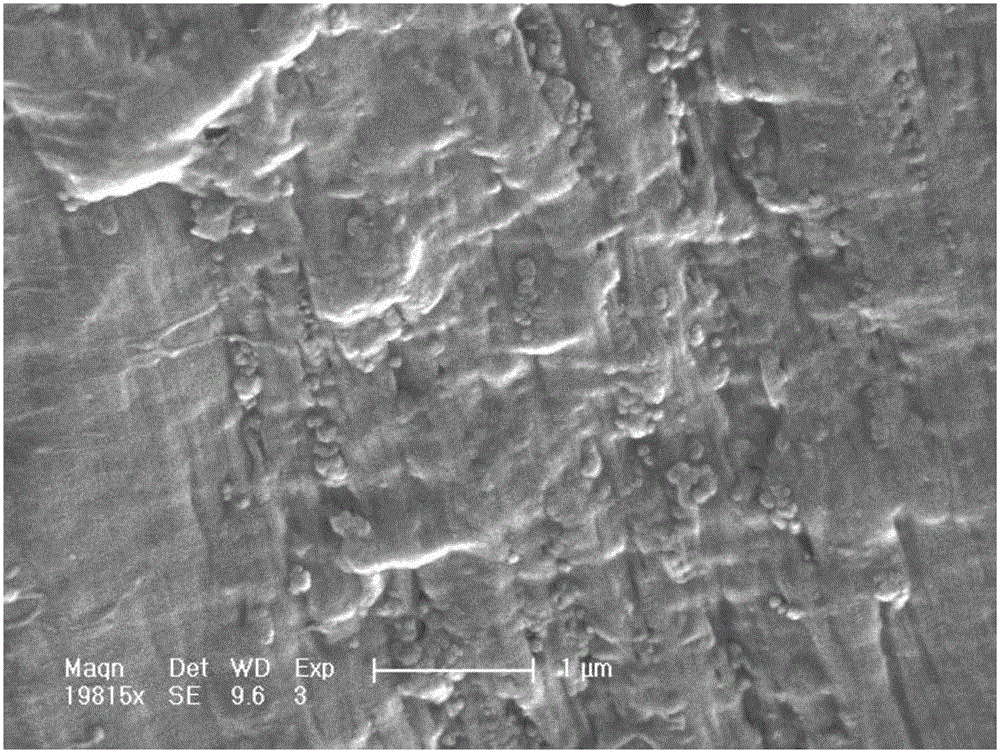

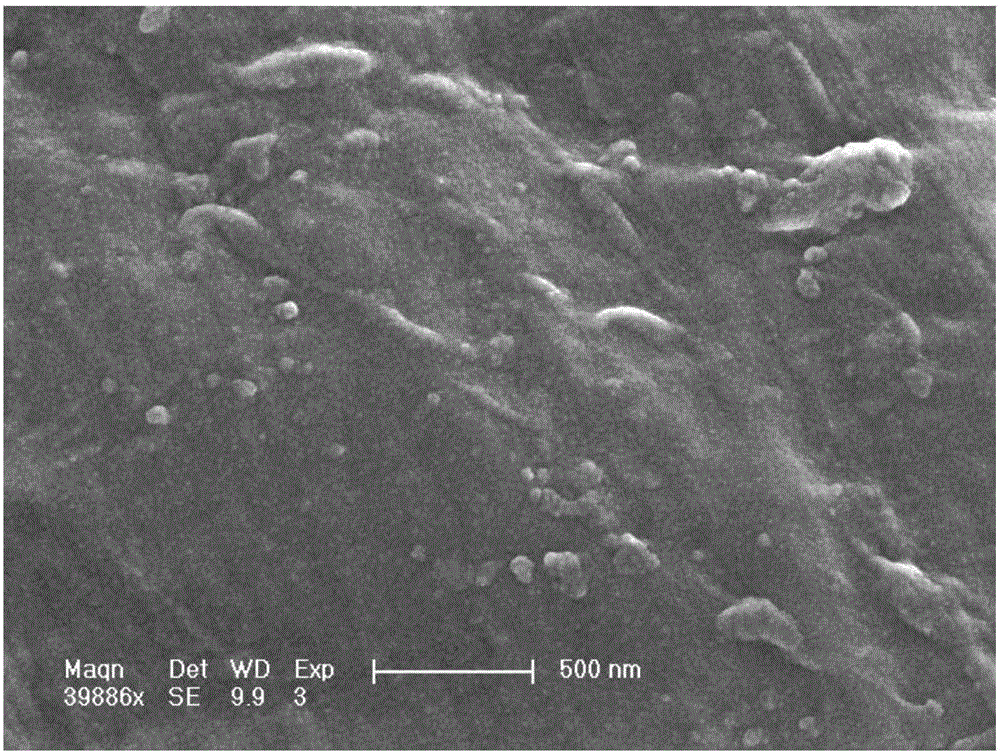

Image

Examples

Embodiment 1

[0020] A kind of inorganic nano particle / polyethylene copolymer composite material, composition content by weight percentage is as follows:

[0021] ingredients weight Linear Low Density Polyethylene 65.5% Ethylene-vinyl acetate copolymer 20% Calcium Carbonate Nanoparticles 10% Zinc Oxide Nanoparticles 2% Titanium Oxide Nanoparticles 1% Antioxidant 1010 1% liquid paraffin 0.5%

[0022] Its preparation method steps are as follows:

[0023] 1) Prepare an aqueous solution of YGO-1203 silane coupling agent with a volume of 1.5%, let it stand for 30 minutes to hydrolyze and dissociate silanol, add calcium carbonate, titanium oxide and zinc oxide nanoparticles, raise the temperature to 60°C, and react for 15 minutes , grafting silanol on the surface of the nanoparticles, drying and grinding at 120°C to disperse the aggregate particles, and preparing silane-modified ternary mixed nanoparticles;

[0024] 2) Add the above-menti...

Embodiment 2

[0028] A kind of inorganic nano particle / polyethylene copolymer composite material, composition content by weight percentage is as follows:

[0029] ingredients weight Linear Low Density Polyethylene 69.7% Ethylene-vinyl acetate copolymer 16% Alumina nanoparticles 5% Titanium Oxide Nanoparticles 7% Antioxidant 1010 1.5% Zinc stearate 0.8

[0030] Its preparation method steps are as follows:

[0031] 1) Petroleum ether was used as a solvent to prepare NDZ-101 titanate coupling agent solution with a volume percentage of 2.5%. After dispersion by ultrasonic and stirring, titanium oxide and aluminum oxide nanoparticles were added, and the temperature was raised to 60°C for 30 minutes of reaction , then volatilize the petroleum ether solvent at 80°C, dry, wash the residual solvent with ultrapure water, grind to disperse the aggregate particles, and prepare titanate-modified mixed nanoparticles;

[0032] 2) Put the above-mentioned...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com