Method for producing high-purity anhydrous magnesium chloride by using bischofite

An anhydrous magnesium chloride and bischite technology, applied in magnesium chloride, magnesium halide and other directions, can solve the problems of equipment corrosion, large ammonia circulation, long reaction time, etc., and achieve low production cost, low consumption and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

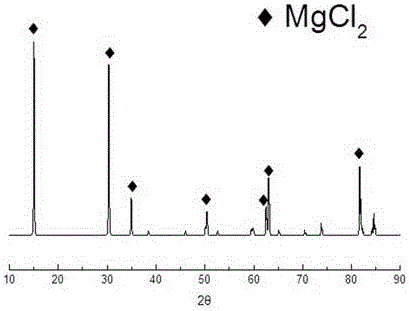

Image

Examples

Embodiment 1

[0037] A kind of method utilizing bischofite to produce high-purity anhydrous magnesium chloride, technological process is as follows figure 1 shown, including the following steps:

[0038] Take 20.33 kg (100 mol) of bischofite, add distilled water to dissolve and prepare a solution with a mass fraction of magnesium chloride of 28%, pass the prepared solution through a centrifugal spray dryer, spray dry at 300°C for 10 seconds, and collect magnesium chloride dihydrate powder. Take all the collected powder and mix it with 32.1kg (600mol) of ammonium chloride evenly, place it in a calciner and calcinate at 600°C for 3 hours, absorb the tail gas (mainly hydrogen chloride) with quicklime solution, and collect the crude product of anhydrous magnesium chloride and ammonium chloride respectively product. Get 10g of anhydrous magnesium chloride crude product and dissolve with distilled water, there is a small amount of white insoluble precipitate, measure the content of anhydrous mag...

Embodiment 2

[0041] A kind of method utilizing bischofite to produce high-purity anhydrous magnesium chloride, technological process is as follows figure 1 shown, including the following steps:

[0042] Take 20.33 kg (100 mol) of bischofite, add distilled water to dissolve and prepare a solution with a mass fraction of magnesium chloride of 35%, pass the prepared solution through a centrifugal spray dryer, spray dry at 200°C for 20 seconds, and collect magnesium chloride dihydrate powder. Take all the collected powder and mix evenly with 10.70kg (200mol) of ammonium chloride recovered from the previous batch of experiments, and then place it in a calciner for calcination at 750°C for 1 hour. Magnesium chloride crude product and ammonium chloride product. Take 10g of the crude product of anhydrous magnesium chloride and dissolve it in distilled water. There is a large amount of white insoluble precipitate. Volumetric titration of magnesium ions and chloride ions yields a content of 81.67% ...

Embodiment 3

[0044] A kind of method utilizing bischofite to produce high-purity anhydrous magnesium chloride, technological process is as follows figure 1 shown, including the following steps:

[0045] Take 20.33 kg (100 mol) of bischofite, add distilled water to dissolve and prepare a solution with a mass fraction of magnesium chloride of 30%, pass the prepared solution through a centrifugal spray dryer, spray dry at 280°C for 10 seconds, and collect magnesium chloride dihydrate powder. Take all the collected powder and mix with 5.35kg (100mol) of ammonium chloride evenly, then place it in a calciner for calcination at 700°C for 0.5h, absorb the tail gas with ammonia water, and collect the crude anhydrous magnesium chloride product and ammonium chloride product respectively. Take 10g of anhydrous magnesium chloride crude product and dissolve it in distilled water, there is a large amount of white insoluble precipitate, titrate the magnesium ion and chloride ion content by volumetric meth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com