Method for measuring residual phosphorus content in wet process phosphate phosphorus gypsum

A technology of phosphophosphogypsum and phosphorus content, which is applied in the direction of weighing by removing certain components, can solve the problems of human injury, environmental pollution, long heating and decomposition time, and corrosion of ventilation equipment, so as to reduce environmental pollution and avoid corrosion experiments The effect of small corrosion of equipment and equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

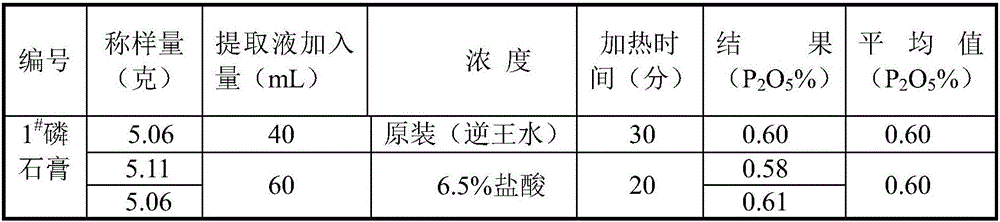

Embodiment 1

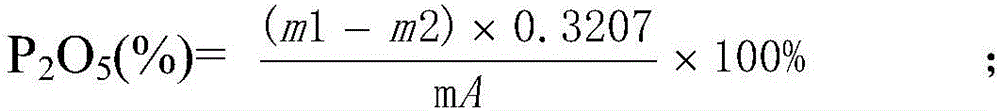

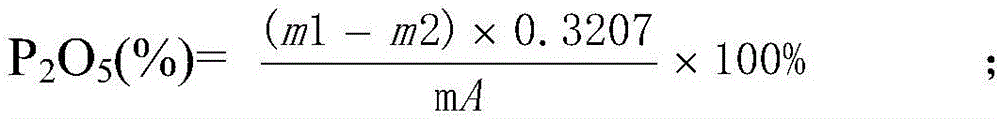

[0042] Take 5 grams of phosphogypsum wet sample, wash it with water until it is neutral, transfer it to a beaker, add 60 mL of hydrochloric acid with a mass fraction of 6.5%, heat to a slight boil for 20 minutes, cool and transfer to a 250 mL volumetric flask, constant volume, shake well, and dry filter , discard the first 20 mL of filtrate. Accurately draw 25.00mL of the filtrate into a 300mL beaker, add 1+1 (made up of 68% reagent grade chemically pure concentrated nitric acid and water volume ratio 1:1) nitric acid 10mL, add water to about 100mL, heat to near boiling, remove Beaker, under constant stirring, add 20mL quincimolicone precipitation agent, carefully heat until the upper solution is clear. Remove the beaker, let it stand for cooling, and filter it with a sand core crucible that has been dried to constant weight. First filter the supernatant, then wash the precipitate 1-2 times by pouring method (approximately 25 mL of water each time), transfer all the precipita...

Embodiment 2

[0056] Take 5 grams of phosphogypsum wet sample, wash it with water until it is neutral, transfer it to a beaker, add 50 mL of hydrochloric acid with a mass fraction of 7%, heat to a slight boil for 20 minutes, transfer it to a 250 mL volumetric flask after cooling, constant volume, shake well, and dry filter , discard the first 20 mL of filtrate. Accurately draw 25.00mL of the filtrate into a 300mL beaker, add 10mL of 1+1 nitric acid, add water to about 100mL, heat to near boiling, remove the beaker, add 20mL of quinolimonone precipitant under constant stirring, and carefully heat to the upper layer solution clear. Remove the beaker, let it stand for cooling, and filter it with a sand core crucible that has been dried to constant weight. First filter the supernatant, then wash the precipitate 1-2 times by pouring method (approximately 25 mL of water each time), transfer all the precipitate to the crucible, and continue to wash the precipitate and the inner wall of the crucib...

Embodiment 3

[0062] Take 5 grams of phosphogypsum wet sample, wash it with water until it is neutral, transfer it to a beaker, add 50 mL of hydrochloric acid with a mass fraction of 7.5%, heat to a slight boil for 20 minutes, cool and transfer to a 250 mL volumetric flask, constant volume, shake well, and dry filter , discard the first 20 mL of filtrate. Accurately draw 25.00mL of the filtrate into a 300mL beaker, add 10mL of 1+1 nitric acid, add water to about 100mL, heat to near boiling, remove the beaker, add 20mL of quinolimonone precipitant under constant stirring, and carefully heat to the upper layer solution clear. Remove the beaker, let it stand for cooling, and filter it with a sand core crucible that has been dried to constant weight. First filter the supernatant, then wash the precipitate 1-2 times by pouring method (approximately 25 mL of water each time), transfer all the precipitate to the crucible, and continue to wash the precipitate and the inner wall of the crucible unt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com