Heat accumulating type skid-mounted protection cover for heat insulation of pressure vessel and making method of heat accumulating type skid-mounted protection cover

A technology for a pressure vessel and a manufacturing method, which is applied in the field of heat-storage skid-mounted protective covers, can solve problems such as uneven temperature difference, falling off of the insulation layer, and corrosion, and achieves the convenience of moving, transportation and installation, and overcomes the falling off of the insulation layer. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will be described in detail with reference to the accompanying drawings.

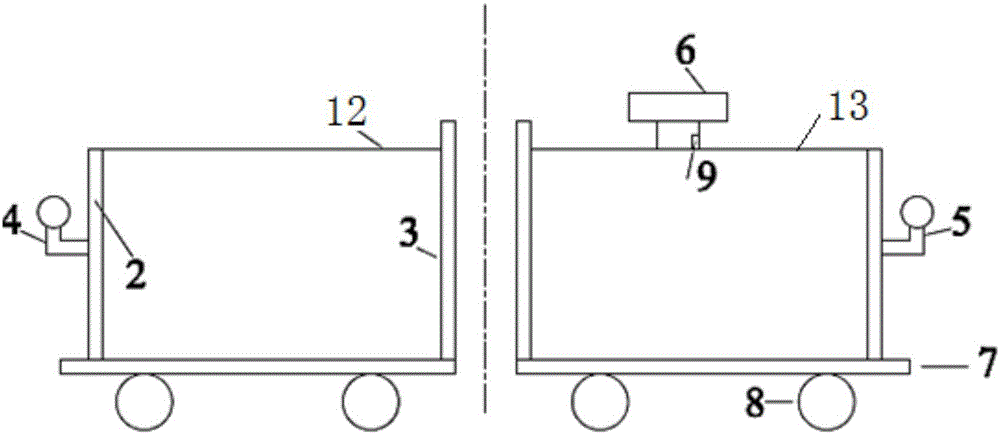

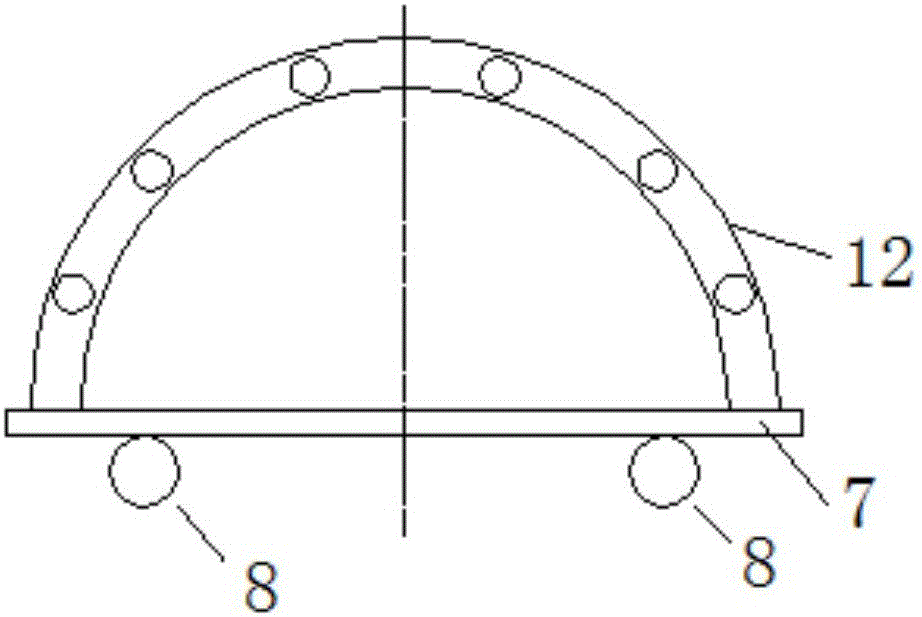

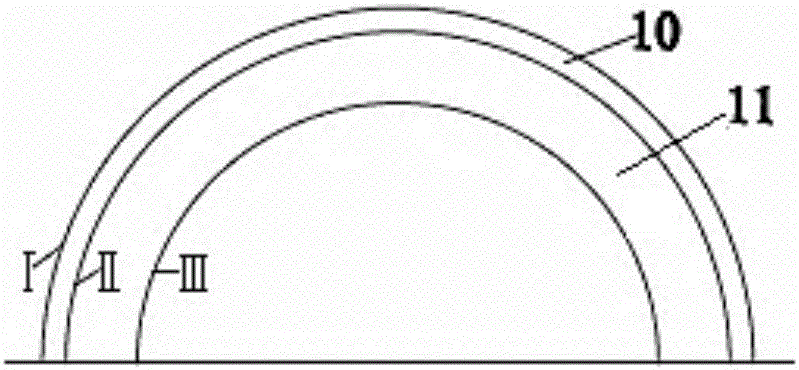

[0034] Such as figure 1 and figure 2 As shown, the cross-section of the thermal storage skid-mounted protective cover for pressure vessel insulation of the present invention is semicircular, including a skid plate 7, a roller 8 is provided at the bottom of the skid plate 7, and a shaft connected along the axial direction is arranged on the skid plate 7. The first semi-cylindrical cover 12 and the second semi-cylindrical cover 13, are connected by flange 3 between the first semi-cylindrical cover 12 and the second semi-cylindrical cover 13; the first semi-cylindrical cover 12 and the second semi-cylindrical cover 13 The ends are provided with end caps 2, the end cap 2 of the first semi-cylindrical cover 12 is provided with a pressure gauge 4, the end cap 2 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com