A kind of consolidated sand system and its preparation method and use method

A system and conjunctival technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of poor strength, poor alkali resistance, insufficient strength, etc., and achieve simple curing conditions, good adhesion performance, high The effect of compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

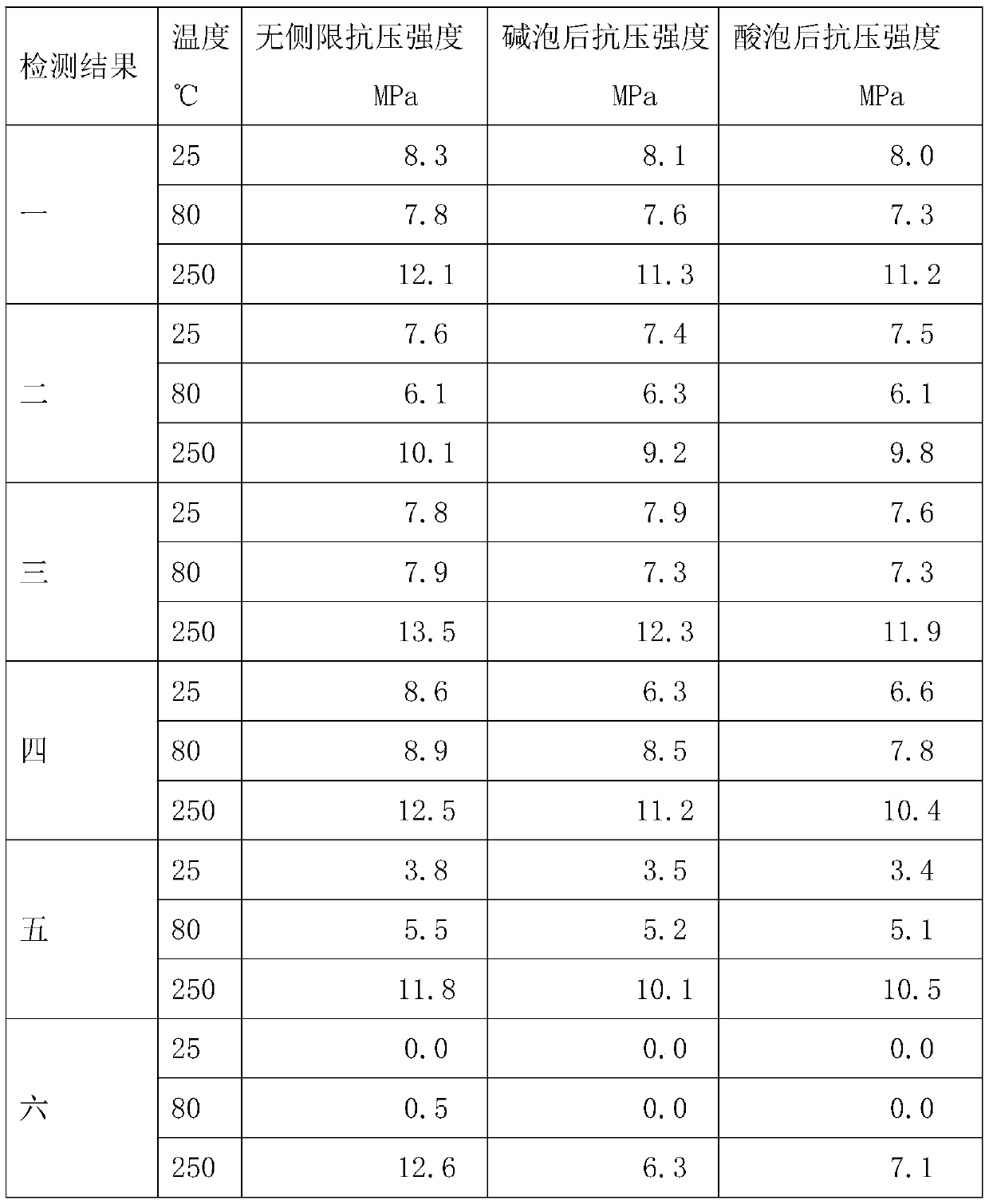

Examples

Embodiment 1

[0029] Select quartz sand with a particle size of 850-425μm as the aggregate, heat 2kg of quartz sand to 350°C, put the quartz sand in a mixer and stir to cool it, and add epoxy modification when the temperature of the quartz sand drops to 230°C 10g of phenolic resin was stirred for 30s, and at this time, the epoxy modified phenolic resin would form a reinforced layer on the outer surface of the aggregate; then add 10g of urotropine aqueous solution with a mass concentration of 10%, and continue to stir for 120 seconds, so that there is a reinforced layer re-disperse the aggregate evenly; add 30g bisphenol A epoxy resin, 30g epoxy modified phenolic resin and 6g diaminodiphenylmethane mixture and stir for 10 seconds, so that the outer surface of the reinforcement layer can form a functional layer, add 6g The mass concentration is 16% urotropine aqueous solution and stirred for 30 seconds to disperse the aggregate again, then add 5ml mass concentration of 0.5% sodium dodecylbenze...

Embodiment 2

[0031] Select quartz sand with a particle size of 850-425μm as the aggregate, heat 2kg of quartz sand to 250°C, put the quartz sand in a mixer and stir to cool it, and add epoxy modification when the temperature of the quartz sand drops to 180°C 45g of phenolic resin was stirred for 10s, and now the epoxy-modified phenolic resin would form a reinforcement layer on the outer surface of the aggregate; then add 30g of urotropine aqueous solution with a mass concentration of 15%, and continue to stir for 15 seconds to make a reinforcement layer The aggregate re-dispersed evenly; then add the mixture of 12.5g bisphenol A epoxy resin, 12.5g epoxy modified phenolic resin and 10g diaminodiphenylmethane and stir for 60 seconds, so that the outer surface of the reinforcement layer can form a functional layer, Adding 30g mass concentration is 20% urotropine aqueous solution and stirring for 15 seconds to disperse the aggregate again, then adding 4ml mass concentration is 1% sodium dodecyl...

Embodiment 3

[0033] Select quartz sand with a particle size of 850-425 μm as the aggregate, heat 2kg of quartz sand to 300°C, put the quartz sand in a mixer to stir and cool it, and add epoxy modification when the temperature of the quartz sand drops to 205°C 100g of phenolic resin was stirred for 60s, at this time, the epoxy modified phenolic resin would form a reinforced layer on the outer surface of the aggregate; then add 50g of urotropine aqueous solution with a mass concentration of 20%, and continue to stir for 30 seconds, so that there is a reinforced layer redisperse the aggregate evenly; add 36g of bisphenol A epoxy resin, 36g of epoxy modified phenolic resin and 1.8g of diaminodiphenylmethane mixture and stir for 30 seconds, so that the outer surface of the reinforcement layer can form a functional layer, adding 3.6g mass concentration is 10% urotropine aqueous solution and stirs for 120 seconds to disperse the aggregate again, then add 3ml mass concentration and then add 5% sodi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com