Process for applying silica powder and superfine slag powder to co-dope tubular pile

A technology of slag micropowder and silicon micropowder, which is used in the manufacture of tools, molds, and reinforcement molding, can solve the problems of low corrosion resistance of pipe piles, and achieve the effects of large weight, high safety, and increased strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

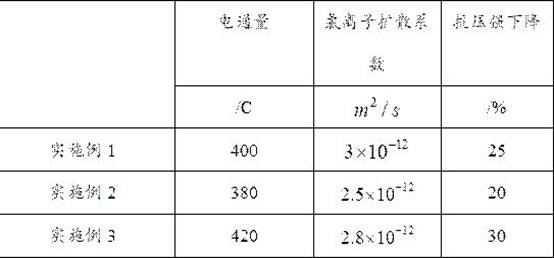

Embodiment 1

[0028] The present invention provides a kind of technology that utilizes micro-silicon powder and slag micro-powder to re-mix pipe piles, comprising the following steps:

[0029] Step 1: Add 150 parts of crushed stone, select particle size of 5mm, 50 parts of finely ground sand, 70 parts of slag micropowder, and 100 parts of silicon micropowder, into the dryer for drying, set the temperature to 80°C, and dry 30 minutes, then take it out and add it to the mixer, add 50 parts of deionized water, 130 parts of cement, 10 parts of water reducer, stir at 90 rpm for 100 minutes to obtain mixture A;

[0030] Step 2: Dehydrate 50 parts of epoxy coal tar pitch, 60 parts of epoxy resin, and 30 parts of phenolic resin at 100°C and a vacuum of 1.2 PMa for 20 minutes, and cool to 30°C to obtain substance B;

[0031] Step 3: Add substance B to substance A, stir at a speed of 130 rpm for 30 minutes, make it fully stirred, mix evenly, and obtain substance D for later use;

[0032] Step 4: Sel...

Embodiment 2

[0042] The present invention provides a kind of technology that utilizes micro-silicon powder and slag micro-powder to re-mix pipe piles, comprising the following steps:

[0043] Step 1: Put 170 parts of crushed stone, select particle size of 10mm, 60 parts of finely ground sand, 80 parts of slag micropowder, and 120 parts of silicon micropowder, into the dryer for drying, set the temperature to 90°C, and dry 30 minutes, then take it out and add it to the mixer, add 50 parts of deionized water, 140 parts of cement, 10 parts of water reducer, and stir at 90 rpm for 30 minutes to obtain mixture A;

[0044] Step 2: Dehydrate 60 parts of epoxy coal tar pitch, 70 parts of epoxy resin, and 50 parts of phenolic resin at 120°C and a vacuum of 1.2PMa for 30 minutes, and cool to 30°C to obtain substance B;

[0045] Step 3: Add substance B to substance A, stir at a speed of 140 rpm for 30 minutes, make it fully stirred, mix evenly, and obtain substance D for later use;

[0046] Step 4: ...

Embodiment 3

[0056] The present invention provides a kind of technology that utilizes micro-silicon powder and slag micro-powder to re-mix pipe piles, comprising the following steps:

[0057] Step 1: Put 170 parts of crushed stone, select particle size of 10mm, 70 parts of finely ground sand, 80 parts of slag micropowder, and 120 parts of silicon micropowder into the dryer for drying, set the temperature to 100°C, and dry After 40 minutes, take it out and add it to a mixer, add 50 parts of deionized water, 140 parts of cement, and 10 parts of water reducer, and stir at a speed of 90 rpm for 30 minutes to obtain mixture A;

[0058] Step 2: Dehydrate 70 parts of epoxy coal tar pitch, 70 parts of epoxy resin, and 60 parts of phenolic resin at 120°C and a vacuum of 1.2PMa for 30 minutes, and cool to 30°C to obtain substance B;

[0059] Step 3: Add substance B to substance A, stir at a speed of 140 rpm for 30 minutes, make it fully stirred, mix evenly, and obtain substance D for later use;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com